In the ever-evolving realm of custom apparel printing, efficiency and quality are crucial, making the **DTF Gangsheet Builder** a game-changer for businesses striving to enhance their production capabilities. This innovative building tool leverages **Direct-to-Film (DTF)** printing technology to harmonize multiple designs onto a single gangsheet, drastically improving printing efficiency. As the demand for high-quality prints intensifies, mastering the utilization of gangsheet printing opens new avenues for businesses to satisfy customer needs effectively. By merging vibrant print capabilities with intelligent design layouts, the DTF Gangsheet Builder empowers print shops to operate competitively in a market that constantly evolves. Join us as we explore how this groundbreaking technique is set to redefine the landscape of custom apparel printing and maximize your operational output.

Exploring the world of printing solutions, the concept of a **DTF gangsheet generator** signifies a pivotal advancement in modern printing methodologies. Leveraging the prowess of **Direct-to-Film (DTF)** techniques, this generator facilitates the simultaneous creation of multiple designs on a single sheet, embodying the principles of gangsheet printing. As businesses adapt to increasing consumer demands, optimizing efficiency through such innovative tools becomes imperative. The synergy between customized graphics and cutting-edge printing technology not only accelerates turnaround times but also enhances overall production quality. As we delve deeper into the advantages and applications of this transformative tool, it’s easy to see why it has become a staple in custom apparel manufacturing.

Understanding the Power of DTF Printing Technology

DTF printing technology has revolutionized the way we approach custom apparel printing, offering superior versatility and quality. Unlike traditional printing methods, DTF uses heat transfer to apply vibrant designs directly onto fabrics, ensuring a wide array of materials—such as cotton, polyester, and blends—can be printed with impressive results. This method eliminates the need for extensive setup changes between different fabric types, allowing for more streamlined production. Consequently, businesses can cater to diverse customer demands without compromising on quality.

Moreover, DTF printing enhances the efficiency of the printing process. As designs are meticulously printed onto specialized transfer film, this allows for high levels of color precision and detailing. Once printed, the designs can be easily transferred using a heat press, ensuring durability and vibrancy in the final product. This blend of efficiency and quality empowers companies to deliver exceptional results consistently, thus reinforcing their market position in the competitive landscape of custom apparel.

Exploring Gangsheet Printing Techniques

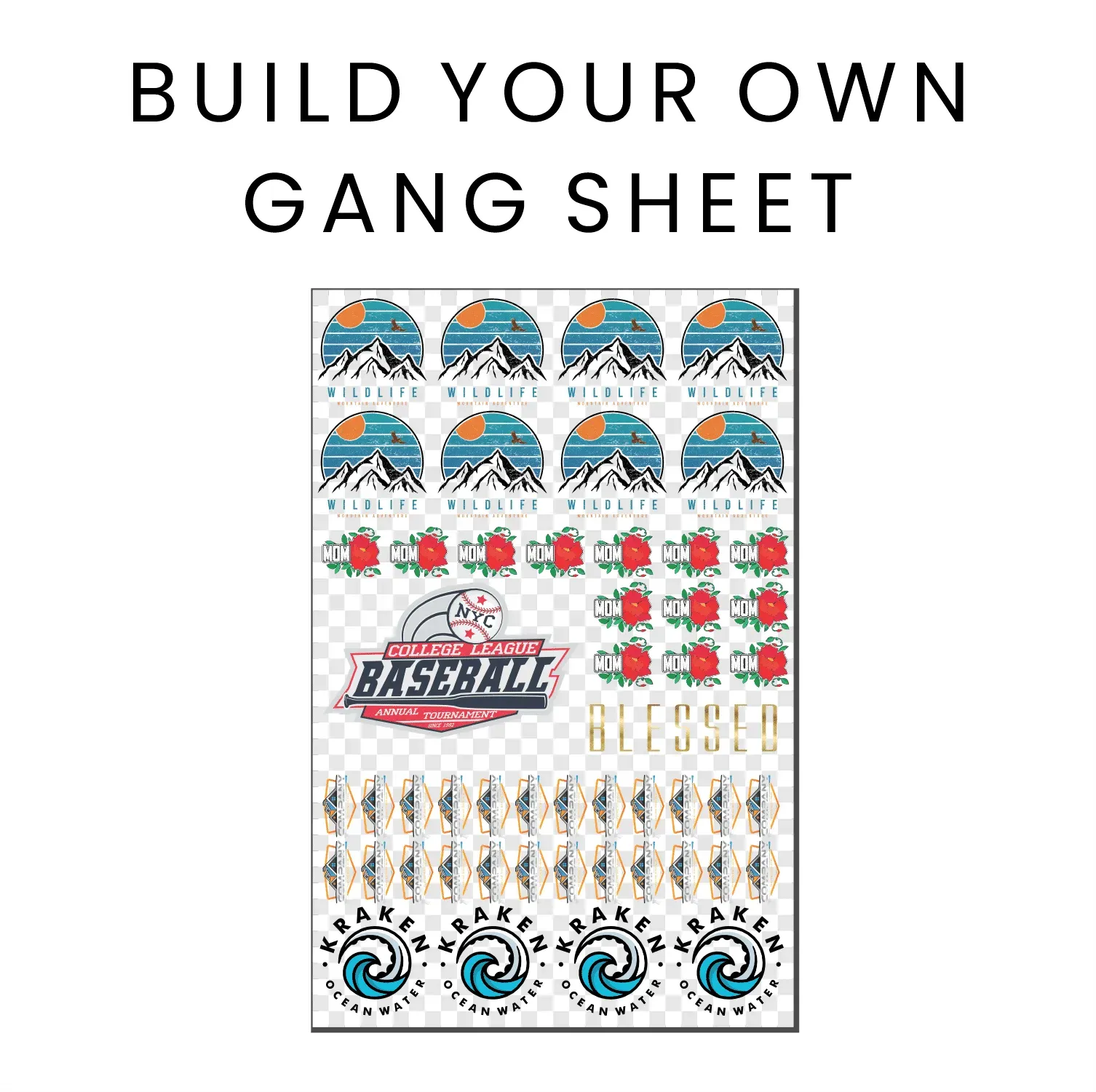

Gangsheet printing is one of the most effective techniques utilized in the DTF printing landscape. By enabling multiple designs to be printed on a single sheet of transfer film, this process minimizes material waste and significantly reduces costs. This practice not only enhances printing efficiency but also allows companies with various client needs to quickly adjust their offerings without extensive reprints. The strategic layout of designs on a gangsheet can optimize ink usage, making it an ideal solution for businesses aiming to boost profitability while maintaining high-quality outputs.

In addition to cost savings, gangsheet printing provides a notable advantage in terms of time efficiency. Businesses looking to fulfill multiple orders can leverage this technique to print several designs simultaneously, resulting in quicker turnaround times. This flexibility empowers companies to manage larger workloads while satisfying diverse customer requests with hastened delivery schedules. Overall, gangsheet printing stands as a cornerstone of efficient production in the custom apparel industry.

Benefits of Implementing a DTF Gangsheet Builder

Incorporating a DTF gangsheet builder into your printing setup offers numerous benefits, particularly in terms of efficiency and cost-effectiveness. By consolidating multiple designs onto a single gangsheet, businesses can significantly reduce material costs and optimize their workflows. This approach is conducive to businesses that frequently tackle multi-design orders, as it allows for a more straightforward production process with fewer materials required. The overall reduction of waste also contributes to more sustainable printing practices, solidifying a company’s reputation in a market increasingly focused on environmental consciousness.

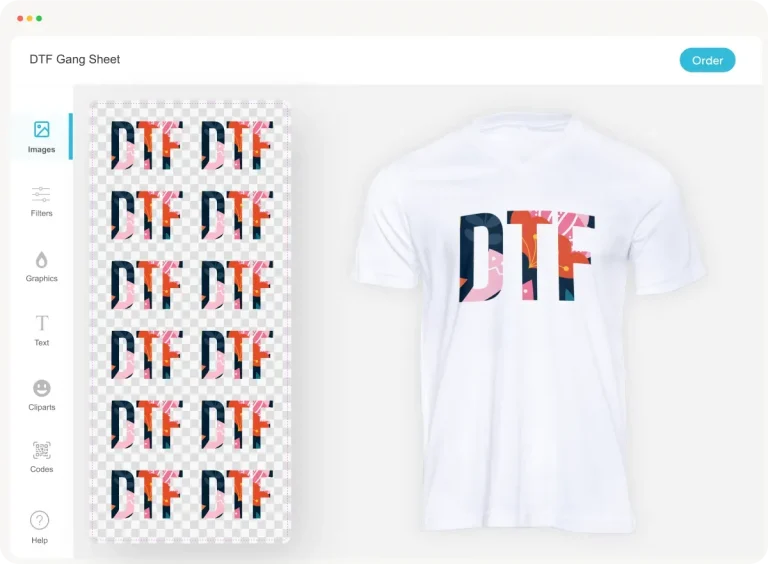

Furthermore, DTF gangsheet builders can streamline operations in a way that enhances the productivity of printing teams. With user-friendly software to arrange and optimize designs, employees can focus on creativity while the system handles printing logistics. Such advancements ease the burden on design processes, leading to noticeable improvements in time management and efficiency. As businesses leverage these benefits, they position themselves strategically within the market, ready to respond swiftly to changing customer demands.

Recent Innovations in DTF Printing Technology

The landscape of DTF printing technology is evolving rapidly, driven by innovations that enhance both printing capabilities and efficiency. Notable manufacturers like Epson, Roland, and Mimaki are pushing boundaries by introducing advanced printers that offer superior color accuracy and faster print speeds. These technological advancements are transforming how businesses execute their printing tasks, making it easier to achieve high-quality results that meet increasing demand.

Additionally, the emergence of software solutions tailored for DTF printing is revolutionizing the users’ experience. Solutions such as Cadlink Software enable print operators to efficiently arrange designs, optimize layouts, and control print sizes, paving the way for a more productive printing environment. These innovations are not only enhancing the user experience but also playing a critical role in the increased adoption rates of DTF gangsheet builders as firms strive for operational excellence.

Best Practices for Using DTF Gangsheet Builders

To maximize the potential of DTF gangsheet builders, employing best practices is essential. Businesses should start by selecting quality software that aligns with their specific needs, emphasizing features that enhance gangsheet layouts and print efficiency. Comprehensive team training on DTF printing techniques and software applications will empower operators to leverage these tools effectively, resulting in significant gains in productivity and output quality.

Another crucial practice is optimizing designs for gangsheet printing. By strategically placing designs on the film, companies can minimize fabric waste and reduce costs while maintaining high-quality print standards. Regular maintenance of printing equipment is equally vital; ensuring that printers are functioning optimally will preserve efficiency and quality, leading to reliable outputs over time. Adhering to these best practices can truly transform the overall printing process for businesses embracing DTF technology.

The Future of Custom Apparel Printing with DTF Technology

As the custom apparel market continues to expand, the future of printing will heavily rely on advanced techniques like DTF technology and gangsheet printing. The growing demand for personalized apparel necessitates innovative solutions that streamline production processes without sacrificing quality. DTF gangsheet builders are poised to become core components of efficient printing operations, enabling businesses to meet customer expectations in both speed and creativity.

Looking ahead, continuous developments in both printing technology and software solutions will likely drive further efficiency improvements and expand capacities in custom apparel printing. Companies that adopt these advancements will be well-equipped to thrive in an increasingly competitive landscape. By embracing DTF technology and implementing effective gaansheet practices, businesses can secure their place as market leaders while pushing the boundaries of what’s possible in fabric customizations.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a specialized tool or software that helps printers create multiple designs on a single sheet of Direct-to-Film (DTF) transfer material. By arranging several graphics efficiently, businesses can maximize material usage and reduce printing costs. This builder streamlines the gangsheet printing process, allowing for speedy transfers onto various fabrics.

How does DTF printing technology enhance custom apparel printing?

DTF printing technology revolutionizes custom apparel printing by enabling vibrant designs to be printed directly onto various fabrics. This method allows for flexibility, as it requires minimal setup adjustments for different materials, ensuring high-quality results with enhanced color accuracy and durability.

What are the advantages of using gangsheet printing with a DTF Gangsheet Builder?

Using gangsheet printing with a DTF Gangsheet Builder offers significant advantages, including cost-effectiveness through reduced material waste, increased efficiency with faster turnaround times, and the flexibility to accommodate multiple designs, catering to varied customer requests in the custom apparel market.

Can DTF Gangsheet Builders support multiple fabric types?

Yes, DTF Gangsheet Builders are designed to support a range of fabric types. The DTF printing technology allows for successful transfers on cotton, polyester, and blended materials, making it ideal for diverse custom apparel printing needs.

What software solutions are best for optimizing DTF gangsheet printing?

Several emerging software solutions, such as Cadlink Software, are tailored specifically for optimizing DTF gangsheet printing. They help users arrange designs, control print sizes, and maximize layouts to reduce waste, ultimately enhancing printing efficiency.

How can businesses stay updated with DTF printing trends and best practices?

Businesses can stay updated with DTF printing trends by participating in online communities and forums focused on DTF printing technology. These platforms provide valuable insights, tips for optimizing gangsheet usage, and shared experiences that can benefit both newcomers and seasoned professionals.

| Key Point | Description |

|---|---|

| What is DTF Printing? | An innovative printing technique allowing vibrant designs to be transferred onto fabrics using heat. |

| Gangsheet Concept | Printing multiple designs on a single sheet to minimize waste and maximize efficiency. |

| Benefits of Gangsheet Printing | Cost-effectiveness, time efficiency, and flexibility in accommodating various product designs. |

| Recent Developments | Emerging software, advancements in equipment, and growing market demand are evolving DTF gangsheet builders. |

| Best Practices | Invest in quality software, train your team, optimize designs, and maintain equipment regularly. |

Summary

DTF Gangsheet Builder revolutionizes the printing process in the custom apparel market by enhancing efficiency and quality. With its innovative approach to DTF printing, businesses can print multiple designs simultaneously on a single sheet, significantly reducing waste and operational costs. As printing technology advances and market demand increases, adopting a DTF Gangsheet Builder not only streamlines production but also positions businesses for competitive success. Therefore, leveraging this powerful tool is essential for any company aiming to thrive in the vibrant world of custom printing.