The DTF gangsheet builder is revolutionizing the way printing businesses operate, significantly enhancing productivity through innovative Direct-to-Film printing techniques. This cutting-edge tool allows for gangsheet creation, enabling multiple designs to be printed concurrently on a single film, which maximizes material efficiency and reduces overall production costs. As the demand for vibrant prints on diverse fabrics continues to soar, leveraging a DTF gangsheet builder can transform your workflow and elevate your brand’s offerings. By incorporating smart design optimization practices, printers can achieve exceptional results while minimizing waste and boosting turnaround times. In this guide, we explore essential strategies to harness the full potential of a DTF gangsheet builder and elevate your printing productivity to new heights.

In the realm of fabric printing, the gangsheet creator has become an indispensable asset for many businesses seeking efficiency and cost-effectiveness. By utilizing direct-to-film methods, this innovative tool allows printers to produce multiple designs in a single print run, streamlining the overall workflow. Optimizing design layouts becomes a seamless process with advanced gangsheet technology, which fosters better resource management and reduces material waste. As industry trends shift towards more complex, colorful prints, mastering DTF printing techniques is not just beneficial but essential for staying competitive. This discussion will introduce best practices for maximizing productivity through effective use of this transformative printing solution.

Understanding the Versatility of DTF Printing

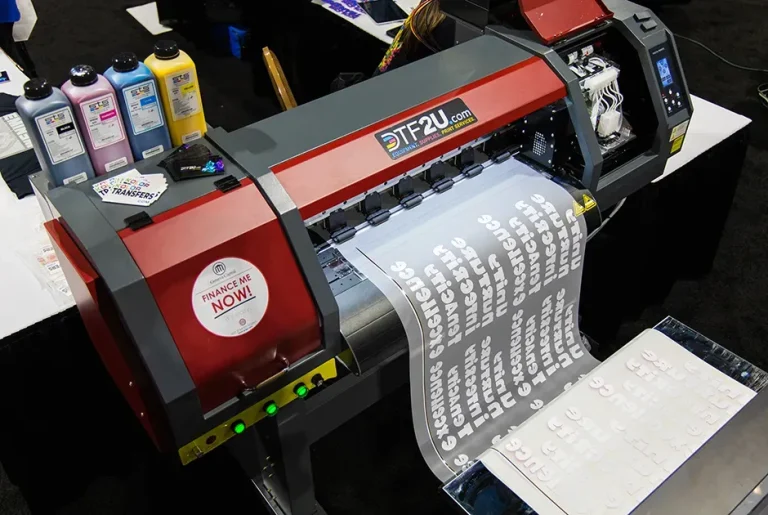

Direct-to-Film (DTF) printing is transforming the fabric printing landscape, offering unmatched versatility for businesses. Unlike traditional printing methods, DTF technology allows for the application of vivid, intricate designs directly onto a range of fabrics, including cotton, polyester, and blends. This capability not only enhances the quality of prints but also opens doors to a broader market, enabling companies to cater to diverse customer needs and preferences.

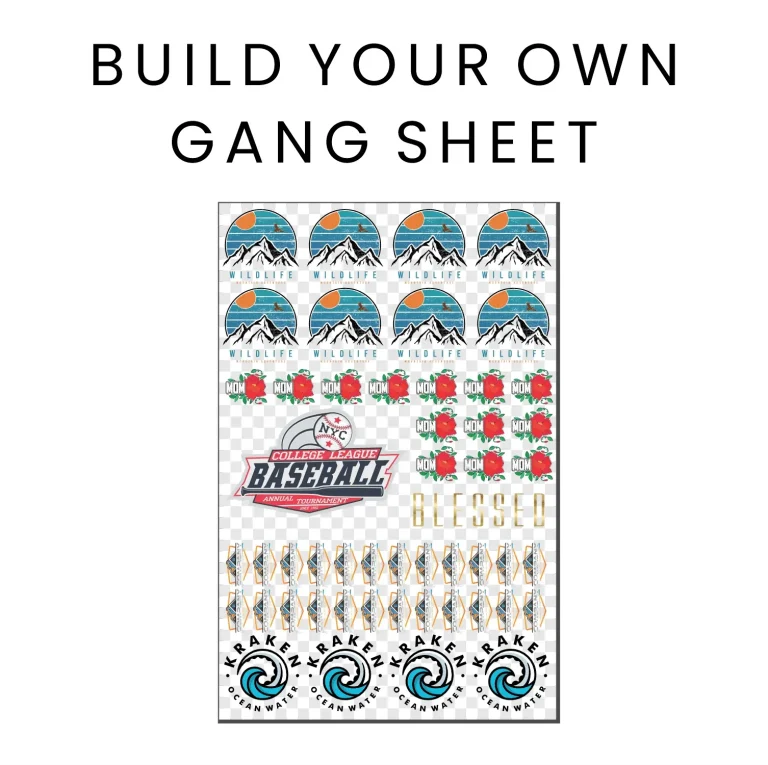

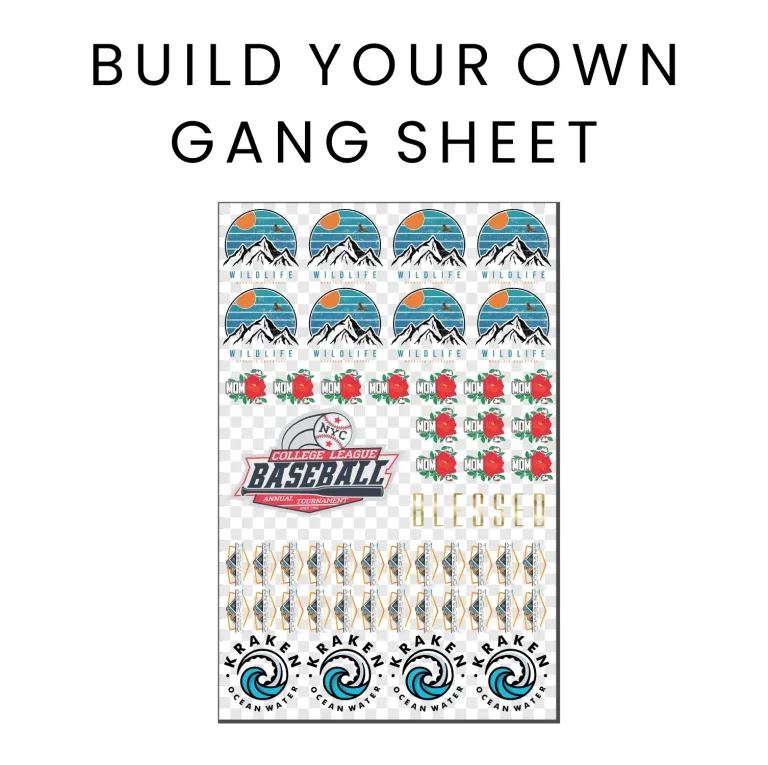

The gangsheet method is particularly advantageous, as it enables multiple designs to be printed simultaneously on a single film. This minimizes waste and optimizes material usage, a crucial factor in driving down costs. By maximizing the efficiency of design layouts, printing operations can achieve significant productivity boosts while delivering high-quality products that resonate with customers.

Step-by-Step Guide to Effective Gangsheet Creation

Creating an effective gangsheet requires careful planning and a methodical approach. Begin by using graphic design software that supports your preferred file formats, ensuring that your designs are compatible with DTF printing. Proper sizing and placement of each design on the gangsheet is imperative for maximizing space; a well-organized layout can reduce excess film usage and lower costs.

Utilizing pre-set templates can simplify the gangsheet creation process, allowing for standardization across various designs. By utilizing these tools, printers can enhance their operational efficiency and lay the groundwork for consistent output quality. Emphasizing meticulous design preparation will ultimately lead to superior print results and help maximize overall productivity.

Maximizing Productivity with DTF Software Features

Investing in the right DTF software is paramount for enhancing printing productivity. Specialized tools designed for gangsheet creation come equipped with features like color accuracy checks and automated design adjustments, saving valuable time during the setup process. Effectively leveraging these features enables printers to streamline their workflow and maintain high-quality standards across all products.

Moreover, keeping software updated with the latest enhancements ensures that operators benefit from improved functionalities, further optimizing the production process. Advanced DTF printing techniques integrated into these programs can also assist in achieving consistent color output and precise replication of designs, which is essential for maintaining a strong brand identity.

Ensuring Quality Control in DTF Printing

Quality control is a vital component of any successful DTF printing operation, particularly when utilizing a gangsheet builder. Conducting trial runs on various fabrics allows for assessment of print durability and overall performance. Utilizing high-quality films and inks is crucial; they play a significant role in ensuring that the final products meet customer expectations and stand the test of time.

Additionally, establishing a routine maintenance schedule for printing equipment can dramatically reduce operational downtime. Regularly cleaning print heads and inspecting equipment allows for smoother production runs. By prioritizing quality control measures, businesses can enhance their output efficiency and deliver products that not only meet but exceed customer satisfaction.

Strategic Material Management for Efficiency

Effective material management is critical for a productive DTF printing environment. By keeping an organized inventory of films and inks, businesses can prevent unnecessary delays that may arise from low stock levels. Implementing an inventory management system allows for better tracking of supplies, ensuring that necessary materials are always available when needed, thus maintaining an uninterrupted production flow.

Regularly assessing inventory levels and reordering supplies in a timely manner can further optimize the workflow. This proactive approach not only contributes to material efficiency but also supports cost management initiatives, making it an essential strategy for any printing operation focused on maximizing productivity.

Streamlining Workflow for Enhanced Output

Workflow optimization is key to achieving higher productivity rates in DTF printing operations. By segmenting tasks among team members, each individual can focus on their areas of expertise, leading to faster and more efficient production. For instance, design specialists can dedicate their efforts to creating artwork, while printing technicians handle the actual printing process.

Utilizing visual tools like flowcharts or checklists can clarify roles and responsibilities among team members, enhancing communication and collaboration. This structured approach minimizes bottlenecks and maximizes throughput, ultimately contributing to a more productive work environment and achieving outstanding printing results.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance Direct-to-Film printing?

A DTF gangsheet builder is a tool used in Direct-to-Film (DTF) printing that allows users to arrange multiple designs on a single sheet of film. This technique not only optimizes material usage but also maximizes printing productivity and reduces costs by minimizing waste.

How can I improve my gangsheet creation process with a DTF gangsheet builder?

To enhance your gangsheet creation process, invest in specialized DTF software that automates layout adjustments and ensures color accuracy. Also, meticulously prepare your designs to maximize space on the gangsheet, allowing for more efficient printing productivity.

What role does design optimization play in using a DTF gangsheet builder?

Design optimization is crucial when using a DTF gangsheet builder because it ensures that every inch of the gangsheet is utilized effectively. Properly sizing and arranging designs maximizes output and minimizes waste, directly impacting overall printing productivity.

What are the key best practices for DTF printing techniques with a gangsheet builder?

Key best practices for utilizing DTF printing techniques with a gangsheet builder include meticulous design preparation, leveraging specialized software, performing regular quality control, and maintaining efficient material management to streamline the workflow.

How do quality control measures affect the productivity of my DTF gangsheet builder?

Quality control measures, such as regular testing on various fabrics and maintaining clean equipment, significantly impact the productivity of your DTF gangsheet builder by minimizing downtime and ensuring high-quality outputs, which leads to greater customer satisfaction.

What are some ways to optimize workflow when using a DTF gangsheet builder?

Optimizing workflow with a DTF gangsheet builder includes segmenting tasks among team members based on their strengths, using visual aids like flowcharts, and encouraging open communication to enhance cooperation and speed up the overall production process.

| Key Point | Explanation |

|---|---|

| Understanding DTF Technology | DTF technology allows for intricate designs on various fabrics using gangsheet printing, optimizing resources and minimizing waste. |

| Design Preparation | Use graphic design software for layout planning to maximize space on the gangsheet and minimize waste. |

| Software Utilization | Invest in specialized DTF software for optimal design arrangement and production efficiency. |

| Quality Control | Conduct tests with high-quality materials to ensure durability and equipment maintenance. |

| Material Management | Keep an organized inventory of films and inks to prevent production delays. |

| Workflow Optimization | Segment tasks based on team member strengths to enhance communication and speed up production. |

| Experimentation and Feedback | Use early runs for experimentation and encourage team feedback for continuous improvement. |

| Training and Education | Regular training sessions are critical for keeping teams updated on DTF advancements and best practices. |

Summary

DTF gangsheet builder is an essential tool that can revolutionize your printing business by enhancing productivity and reducing costs. By incorporating best practices such as meticulous design preparation, efficient software utilization, and rigorous quality control, you can maximize the output of your DTF operations. Embracing a culture of continuous improvement and education ensures your team remains competitive in an ever-evolving industry. As you implement these strategies, watch your productivity soar, positioning your printing business for long-term success.