DTF gangsheet builder is a powerful tool that reshapes how you plan designs on a single print sheet, turning potential waste into precise, scalable layouts that align with production goals, color rules, and deadline pressures. It guides you through the entire prepress process, coordinating margins, print areas, and color separations so you can move from idea to production with confidence while minimizing reprints and bottlenecks. By centralizing layout decisions, teams experience faster setups, fewer misalignments, and more consistent results across orders, enabling designers and operators to collaborate more effectively and respond to urgent requests without sacrificing quality. The emphasis on gangsheet optimization helps ensure every inch of the sheet is used effectively, driving cost savings and streamlined workflows that scale as product lines expand and seasonal campaigns come online. Across projects, this strategic approach supports ongoing improvement, enabling better planning, clearer communication, and scalable efficiency as demand grows, while still leaving room for experimentation and iterative refinement.

Seen through a different lens, this kind of tool functions as a sheet layout planner for garment transfers, helping teams arrange artwork efficiently across large print runs. Rather than a single feature, it acts as a planning engine that coordinates margins, safe zones, and print areas while accommodating different garment types. From a production perspective, you gain workflow optimization, repeatable prepress steps, and improved color management, all aimed at reducing setup times and material waste. By framing the concept with terms like layout optimization, print-ready tiling, and transfer-ready schematics, designers and operators can align creative intent with practical constraints.

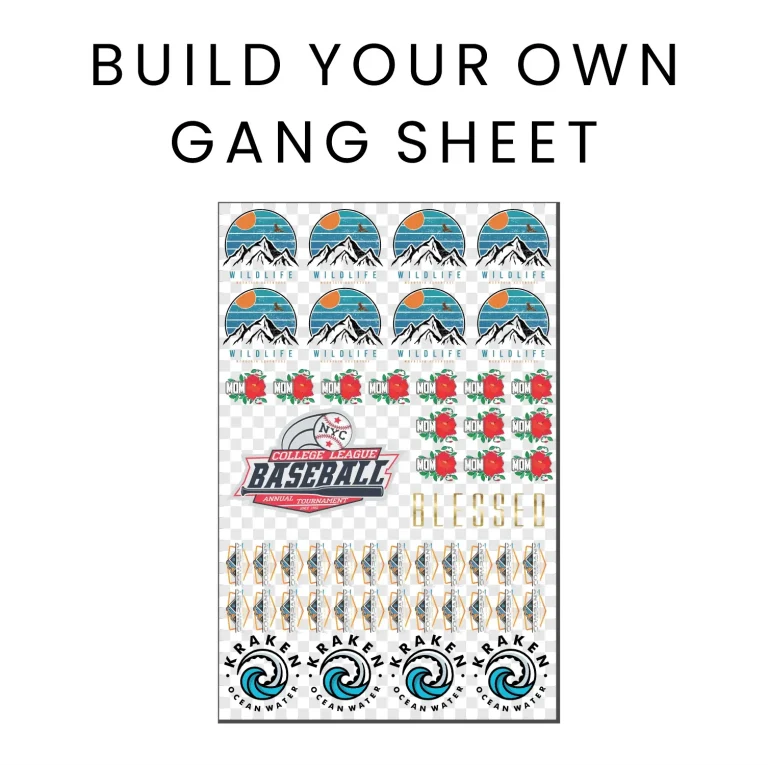

DTF gangsheet builder: How this tool boosts DTF printing efficiency and layouts

A DTF gangsheet builder is a planning tool that helps you plan, tile, and optimize designs across a single sheet. By considering margin allowances, printer capabilities, color separations, and garment sizes, it supports better DTF gangsheet layouts and enables gangsheet optimization to minimize waste and costs. Using this approach, you set a solid foundation for repeatable projects and a streamlined workflow that benefits the entire team.

With a quality gangsheet builder, you establish a repeatable process that enhances DTF printing efficiency and drives maximize sheet utilization. The framework also supports layout ideas for DTF, helping you design sheets that accommodate multiple designs without sacrificing print quality, reducing setup time and material waste.

Layout ideas for DTF: Maximizing sheet utilization through optimized gangsheet layouts

Creative layout ideas for DTF can be implemented through concepts like mosaic grids or thematic clusters, all of which contribute to better DTF gangsheet layouts. For example, assembling a mosaic of micro-designs in a uniform grid packs many small motifs onto one sheet, ensuring every inch is utilized while maintaining consistent margins for clean cuts and predictable post-processing.

Beyond grids, ideas such as size-based tiling, mirrored or rotated repeats, color-conscious packing, and orientation-aware layouts help optimize gangsheet layouts and improve DTF printing efficiency. Planning for color separations, reserved zones for future tweaks, and prototype testing further supports gangsheet optimization and reduces waste, delivering more reliable, scalable production.

Frequently Asked Questions

DTF gangsheet builder: How does it improve DTF gangsheet layouts to maximize sheet utilization and boost DTF printing efficiency?

Using a DTF gangsheet builder, you can plan, tile, and optimize designs across a single sheet—accounting for margins, printer capabilities, color separations, and garment sizes. It enforces consistent DTF gangsheet layouts, supports logical groupings and predictable color orders, and drives gangsheet optimization. The result is maximum sheet utilization, reduced waste, shorter setup times, and improved DTF printing efficiency, with a repeatable process for future projects.

What are practical layout ideas for DTF when using a DTF gangsheet builder to achieve gangsheet optimization and maximize sheet utilization?

Use practical layout ideas for DTF with a DTF gangsheet builder to maximize sheet utilization and improve DTF printing efficiency: 1) Mosaic of micro-designs—grid of small motifs; 2) Thematic clusters—group related designs by theme; 3) Size-based tiling—tiered rows for different sizes; 4) Mirrored and rotated repeats—creative symmetry; 5) Color-conscious packing—group by color blocks; 6) Bleed-friendly grids—allow minimal bleed; 7) Multi-garment compatibility—plan for different products; 8) Reserved zones for future tweaks—leave space for adjustments; 9) Orientation-aware layouts—portrait and landscape mixed; 10) Prototype-first approach—test prints. A DTF gangsheet builder automates grid setup, margins, and color planning to support these ideas and improve sheet utilization and overall DTF printing efficiency.

| Aspect | Key Points | Benefits |

|---|---|---|

| Purpose of a DTF gangsheet builder | Plan, tile, and optimize designs on a single sheet; accounts for margins, printer capabilities, color separations, and garment sizes | Reduces waste and material costs; creates a repeatable workflow |

| Core principles of DTF gangsheet layouts | Know base sheet size, print area, material; balance margins, color separations, and logical groupings; plan color order and ink usage | Improved efficiency and easier post-processing |

| 1) Mosaic of micro-designs | Uniform grid with tight spacing to pack small motifs | Maximizes sheet utilization; supports many small designs |

| 2) Thematic clusters | Group related designs by theme; align by color families; easy to rotate sheets | Simplifies color management and reordering |

| 3) Size-based tiling | Bands by size; balance sheet; reduce waste with varying design sizes | Better sheet balance for multi-size orders |

| 4) Mirrored and rotated repeats | Strategic mirroring and rotation for symmetry | Visual impact with efficient use of space |

| 5) Color-conscious packing | Pack designs so color layers align; know separations | Reduces color-change time; consistent results |

| 6) Bleed-friendly grids | Account for bleed; placeholders for slight misalignments | Fewer reprints; smoother throughput |

| 7) Multi-garment compatibility | Single sheet for shirts, hoodies, totes; plan print areas | Versatility and efficient sheet utilization |

| 8) Reserved zones for tweaks | Leave space for additions or edits | Flexibility for urgent orders |

| 9) Orientation-aware layouts | Mix portrait and landscape on one sheet | Maximize space usage; varied design fit |

| 10) Prototype-first approach | Test prints to refine margins, color alignment, and transfer quality | Reduces waste; data for future projects |

| Optimizing workflow with the gangsheet builder | Automate grid setup, margin calculation, and color-block planning; pair with SOPs | Speeds prepress, reduces human error, accelerates turnaround times |

| Common pitfalls and how to avoid them | Overcrowding, misalignment risks; standardize safe margins; run test prints | Prevents waste and misregistration; keeps teams aligned |

| Tools and tips for success | Choose a high-quality gangsheet builder; predefined color strategy; library of layouts; update regularly; document best practices | Ensures consistency, faster iteration, and ongoing optimization |