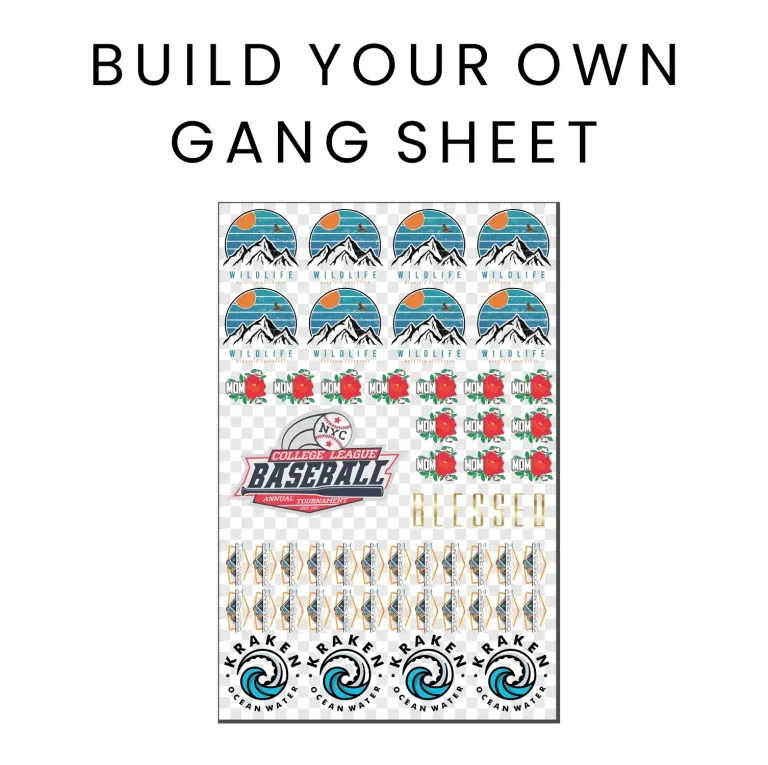

DTF Gangsheet Builder is a game-changer for batch transfers, combining design agility with production speed. In this intro, we explore how the tool orchestrates an efficient workflow for textiles. With the ability to arrange several designs on a single gangsheet, it enables you to produce more transfers quickly without sacrificing quality, helping print runs scale. For those seeking guidance, a DTF gangsheet tutorial can walk you through layouts, margins, and export settings to ensure consistent results. From planning to press, this approach optimizes material use, reduces setup time, supports faster fulfillment for your clothing line, and scales smoothly with growing product catalogs.

When designers think about batch printing and design consolidation, the concept often called gangsheet creation emerges as a core efficiency driver. Another way to describe it is as a sheet-based layout tool that groups multiple designs for a single print, reducing handling steps and aligning color layers. From a broader perspective, it supports a streamlined DTF workflow by optimizing material usage, print planning, and post-press finishing. Understanding these terms helps operators adopt best practices in creating DTF transfer sheets, managing color accuracy, and delivering consistent results at scale.

DTF Gangsheet Builder and the DTF Printing Workflow: Efficient Large-Scale Transfers for Textiles

Using a DTF Gangsheet Builder consolidates multiple designs into a single gangsheet, reducing media changes, cutting setup time, and ensuring consistent ink depth across transfers. This approach supports gangsheet DTF transfers at scale and is especially useful for bulk runs and e-commerce catalogs. As outlined in a DTF gangsheet tutorial mindset, this workflow emphasizes grid-based layouts, precise gutters, and efficient color planning to maximize sheet utilization while preserving print quality on textiles.

Beyond planning, the core workflow steps include defining sheet parameters, importing designs as PNGs with transparent backgrounds, enabling snap-to-grid, planning color layers and white underbase, and exporting print-ready files. This aligns with the DTF printing workflow and helps ensure consistent results across devices. When you build a library of templates, you can produce more designs quickly without sacrificing color accuracy, edge definition, or wash durability.

Creating DTF Transfer Sheets for Textiles: Best Practices for Color, Coverage, and Durability

Creating DTF transfer sheets for textiles requires careful color management and material considerations. You’ll typically separate the white underbase for dark fabrics and overlay color layers to achieve opacity, saturation, and edge durability. DTF transfers for textiles depend on fabric type (cotton, blends, poly blends) and ink profiles, making testing on target fabrics critical. This is where following a structured approach—rooted in creating DTF transfer sheets—helps ensure predictable results across runs and reduces reprints.

Practical best practices include calibrating color management with ICC profiles, planning margins and gutters, and validating designs with test prints. This aligns with the broader DTF printing workflow and the goal of high-quality textile transfers. Regular quality control, archiving templates, and maintaining a library of ready-to-use gangsheet configurations help scale production while maintaining consistency and reducing waste.

Frequently Asked Questions

How does the DTF Gangsheet Builder improve efficiency for DTF transfers for textiles in bulk runs?

The DTF Gangsheet Builder lets you lay out multiple transfer designs on a single gangsheet, reducing media changes, reprints, and setup time. By using a grid-based layout, managing color and white underbase layers, and exporting print-ready files compatible with your RIP, it supports a streamlined DTF printing workflow and more efficient DTF transfers for textiles.

What features should I look for when choosing a DTF Gangsheet Builder to aid in creating DTF transfer sheets?

Key features include a grid-based layout with configurable sheet sizes, robust color management, clear layer organization (white underbase and color layers), and export formats that fit your RIP. Importing and aligning artwork easily and preserving layer order are important too. If you’re new, a DTF gangsheet tutorial can guide you through creating DTF transfer sheets and optimizing your workflow.

| Topic | Summary | Practical Takeaway |

|---|---|---|

| DTF Printing Basics | Direct-to-film printing delivers vibrant colors, strong adhesion, and broad textile compatibility, enabling scalable transfers. | Foundational understanding of why gangsheet workflows matter. |

| DTF Gangsheet Builder | A specialized software/tool that layouts multiple transfer designs onto one sheet so you print, press, and ship many designs in a single run. | Core efficiency tool for bulk DTF production and consistency. |

| Why Use Gangsheet | Improves efficiency, consistency, reduces costs, speeds fulfillment, and enables versatile repurposing of layouts. | Primary justification for adopting gangsheet workflows. |

| Key Features to Look For | Grid-based layout, flexible sheet sizes, color management, layer organization, export formats, and design import/alignment. | Guides evaluation of DTF gangsheet tools. |

| Getting Ready | Plan, gather artwork, ensure high resolution (≥300 DPI), use transparent PNGs or vector files, consider fabrics, and decide color separations. | Prepares assets and settings for reliable gangsheet creation. |

| Step-by-Step Guide (Overview) | Defines sheet parameters, imports designs, lays out grid, plans color layers/white underbase, optimizes spacing, checks color accuracy, exports print-ready files, prints/cures/presses, performs post-press checks, and archives templates. | Represents the structured workflow to produce gang sheets. |

| Best Practices | Calibrate color management, maintain a repeatable workflow, implement quick QC checks, manage assets, ensure proper drying/curing, test on target fabrics, document processes. | Improves quality and consistency across runs. |

| Real-World Considerations | Fabric color/texture affects density and white underbase; adjust color palettes; sometimes separate gang sheets for white-on-dark vs full-color designs. | Guides color decisions and sheet planning for different fabrics. |

| Troubleshooting | Misalignment, color shifts, white underbase not registering, ghosting, edge bleed. | Provides problem areas to check during production. |

| Case Study | 500-unit run using gangsheet per design group on 16×20 sheets; 12–16 transfers per run; reduced setup time and waste; faster fulfillment. | Demonstrates tangible efficiency gains. |

| FAQs | Software needs, template reuse, color on dark fabrics, garment types, metrics to track. | Addresses common questions and operational concerns. |

Summary

DTF Gangsheet Builder is a transformative tool in garment decoration, enabling you to plan, group, and print multiple transfers on a single sheet, speeding production and reducing waste. By organizing designs into gang sheets, you can maximize material usage, ensure consistent ink density, and shorten setup times for bulk runs. This workflow suits small shops and larger production lines alike, supporting rapid turnarounds for e-commerce listings and custom orders. Effective use involves careful pre-planning, accurate color management, and a repeatable post-print process including curing and press parameters. With templates and standardized margins, the DTF Gangsheet Builder helps maintain design fidelity across garments and fabrics, while offering scalable capacity as orders grow. In summary, adopting this tool improves efficiency, consistency, and profitability in DTF transfers.