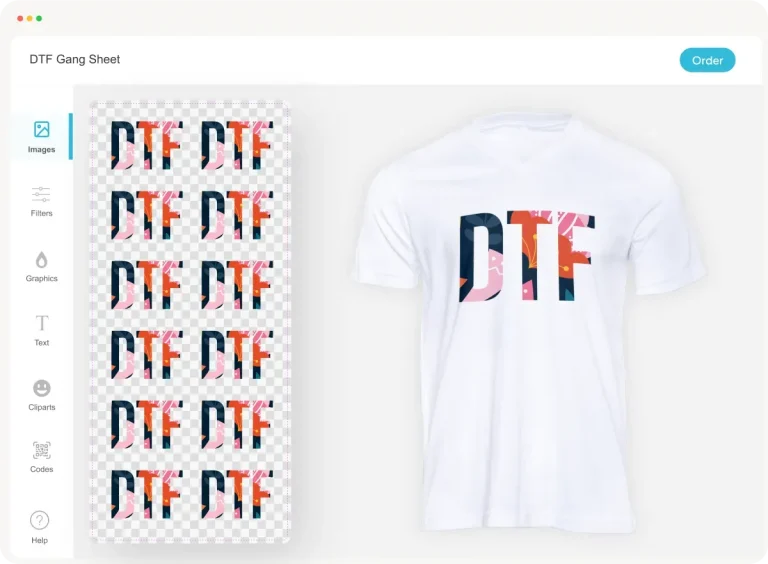

DTF Gangsheet Builder unlocks efficient, scalable workflows for apparel and product customization by assembling multiple designs onto a single gang sheet while preserving color integrity, registration, and predictable output across batches in busy production environments, achieved through modular templates, standardized color targets, and data-driven planning that accommodates varying garment types and print runs. As a result, DTF gangsheet printing becomes more predictable and cost-efficient, with tighter registration, better ink utilization, and less wasted film, enabling shops to maximize press time while maintaining repeatable results across runs, and by standardizing setup sheets and documenting nozzle checks, shops reduce onboarding time and maintain results when teams rotate. Focusing on color accuracy in DTF, operators calibrate printers, palettes, and separation strategies, implement linearization and soft-proofing steps, and verify that hues remain consistent across fabrics, finishes, and design revisions; a robust preflight checklist helps catch file issues before printing, ensuring the gangsheet holds up to long production days and multiple proofs. DTF alignment best practices come into play as you lock rotation, margins, and marks, optimize gutter space, and verify edge-to-edge registration, keeping every design aligned from the first pass to the final trim with confidence; investing in repeatable fixtures, dedicated calibration routines, and clear process documentation also supports training and scaling into new markets. Know when to use ganging sheets for DTF and how to optimize DTF printer setup to support repeatable runs with minimal color drift, while documenting lessons learned for future jobs and audits, and ultimately, these practices translate into fewer reprints, faster turnarounds, and higher client satisfaction while maintaining fabric compatibility.

DTF Gangsheet Builder: Color Management and Alignment Best Practices

Color management in the DTF Gangsheet Builder workflow begins long before the press. Start with printer calibration and RIP workflow alignment so that color output matches your ICC profiles for the specific media and ink set. Build or procure standardized color profiles for DTF and embed them into the job to keep color space consistent across the gang sheet. Create and use color charts or patches during setup to verify that color values stay within tolerance, reducing surprises in production. This approach is central to DTF gangsheet printing, ensuring that hues, gradients, and skin tones remain faithful across designs and fabrics.

Registration accuracy hinges on robust alignment practices. Define clear registration marks, plan margins and bleeds, lock rotation and scale across all designs, and ensure consistent media handling. When you verify substrate alignment separately from the gang sheet, you prevent misregistration caused by garments or accessories. Together, these steps form the backbone of DTF alignment best practices in a multi-design gangsheet, helping keep prints crisp and predictable even as the batch size scales.

Ganging Sheets for DTF: Layout Strategies, Templates, and Printer Setup

Layout strategy for ganging sheets for DTF focuses on throughput and color coherence. Group high-color-density designs with compatible color channels on the same sheet to minimize color drift and head travel, design uniform print areas, and choose sheet size and orientation to minimize waste. Use templates and nesting in your RIP to reproduce repeat runs with consistent margins and gutters, while keeping DTF printer setup simple and reliable. A reliable DTF printer setup is essential for consistent results and efficient gangsheet production.

Proofing and validation complete the loop. Run small test patches with color checks, verify registration marks, and document issues encountered for continuous improvement. A rigorous verification process — including color accuracy checks, alignment tests, and notes on any media or ink changes — reinforces DTF printer setup and ensures that ganging sheets for DTF deliver repeatable results across jobs. By combining robust layout templates with disciplined proofing, you create a scalable workflow that reduces waste and speeds production.

Frequently Asked Questions

How does the DTF Gangsheet Builder enhance color accuracy in DTF gangsheet printing?

The DTF Gangsheet Builder helps enforce a robust color workflow across the entire gang sheet. Key steps include calibrating your printer and RIP, using standardized color profiles for DTF, embedding ICC profiles in the job, applying color separations that preserve intended hues, and preparing color charts that you verify with a colorimeter. By locking a shared color profile for the sheet’s space and allowing designs to adjust only within that framework, you minimize color shifts and maintain color accuracy in DTF printing.

What are the DTF alignment best practices when ganging sheets for DTF using a DTF Gangsheet Builder?

DTF alignment best practices for gang sheet work start with clear and repeatable registration marks placed at predictable locations. Plan margins and bleeds to prevent edge gaps, lock rotation and scaling across all designs, and ensure consistent media handling and film loading. Verify substrate registration on garments in addition to the gang sheet, and use templates for repeat jobs. Finally, perform quick proofing to catch misalignment before full production and keep a log of issues to continuously refine your DTF Gangsheet Builder workflow.

| Area | Key Points |

|---|---|

| DTF Gangsheet Builder Purpose | – Organizes multiple designs on a single gang sheet – Preserves color integrity and registration accuracy – Increases throughput and reduces waste – Streamlines cut lines and print timing |

| Color Management | – Calibrate printer and RIP; embed ICC profiles – Use standardized color profiles for media/ink – Thoughtful color separation and spot colors; simulate previews; avoid clipping – Include color charts/patches; verify with a colorimeter – Maintain consistent color space across designs; lock shared profile |

| Alignment & Registration | – Define clear registration marks – Plan margins/bleeds; safe zones between designs – Lock rotation and scaling across designs – Consistent media handling; ensure even tension – Verify substrate registration (garment seams, etc.) |

| Layout Strategies | – Group by color complexity – Respect uniform print areas – Consider substrate size and orientation – Create templates for repeat runs – Build in quality checks |

| Printer Setup & Hardware | – Maintain ink flow and head health – Calibrate media handling – Optimize print modes for color and speed – Use appropriate films and pre-treatments – Keep a clean workflow environment |

| RIP Software & Workflow | – Prepare color separations and spot colors in the RIP – Use soft proofing and go/no-go testing – Automate ramping and downscaling with care – Leverage nesting features – Maintain version control |

| Proofing & Troubleshooting | – Print test patches and color checks – Inspect for banding and color shifts – Validate alignment across the entire gang sheet – Document issues and adjust |

| Best Practices Checklist | – Establish and lock color profiles for each media/ink set – Use clear registration marks and consistent margins – Maintain printer and substrate maintenance routines – Build templates and nested layouts for repeat jobs – Verify proofs with objective color measurements – Validate alignment and spacing before production |

Summary

This HTML table summarizes the essential concepts from the provided content on DTF Gangsheet Builder, highlighting purpose, color management, alignment, layout strategies, printer setup, RIP workflow, proofing, and best practices. Use these points to guide your DTF gangsheet projects toward consistent color accuracy, precise registration, and efficient production.