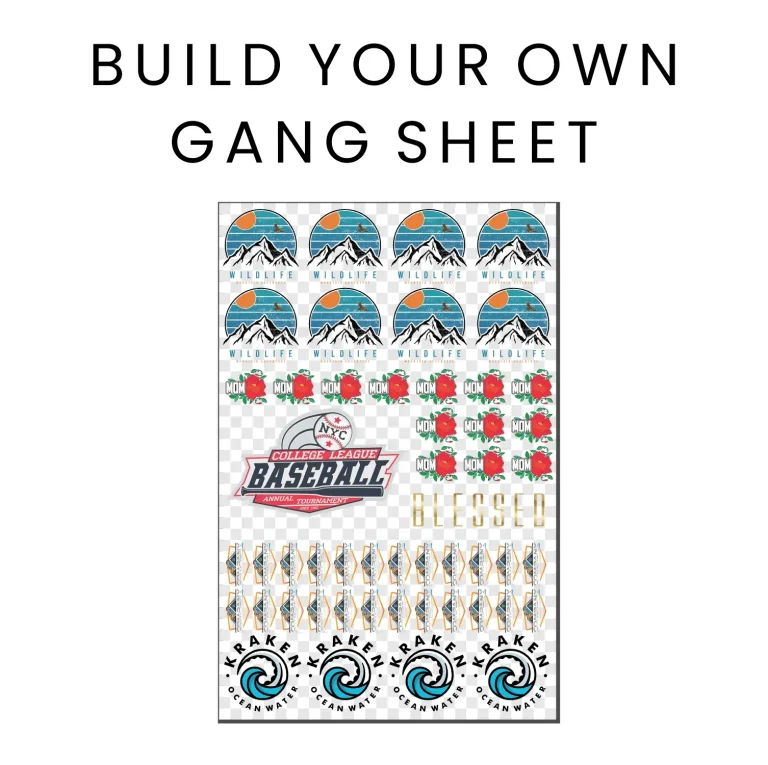

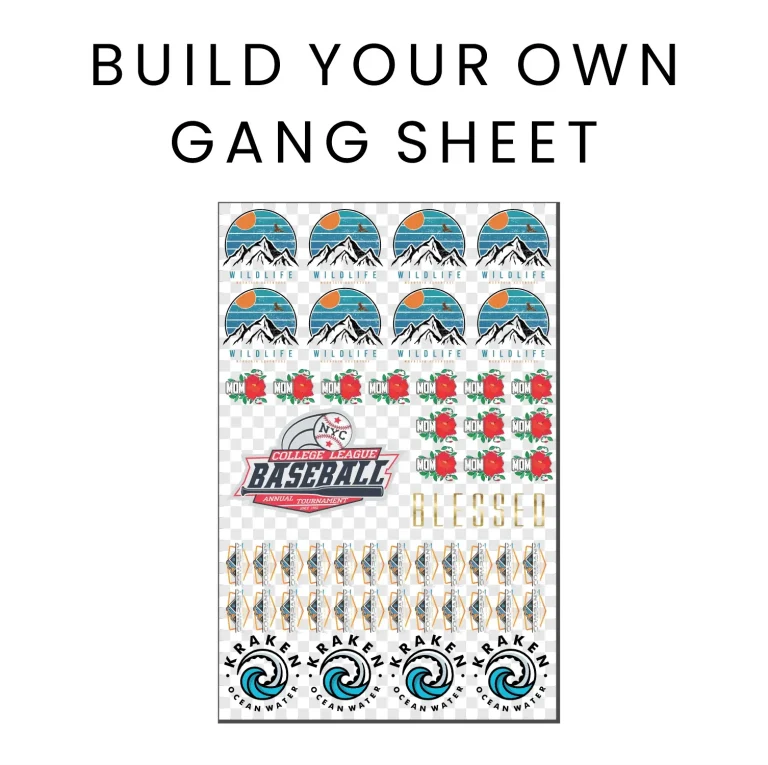

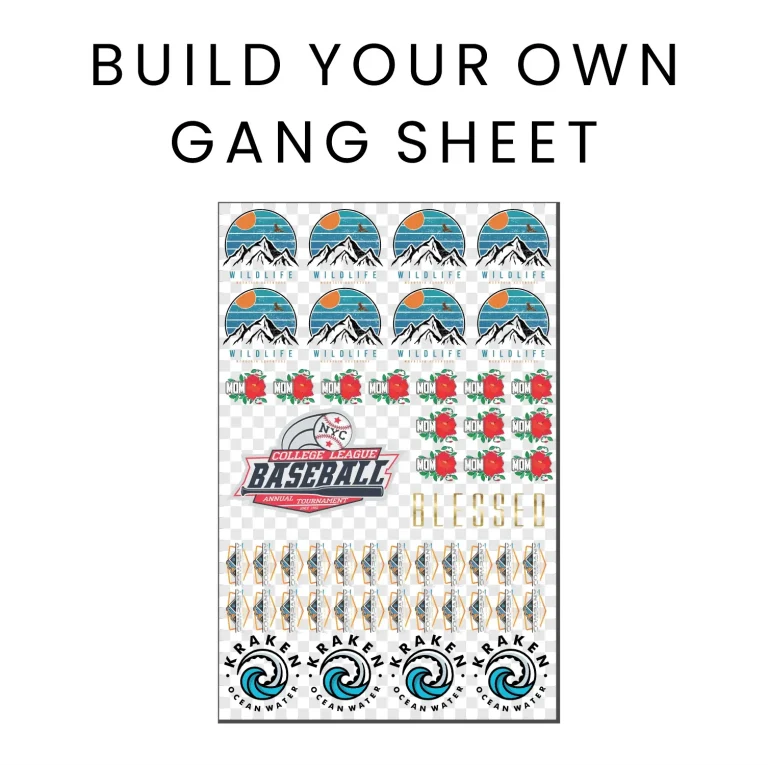

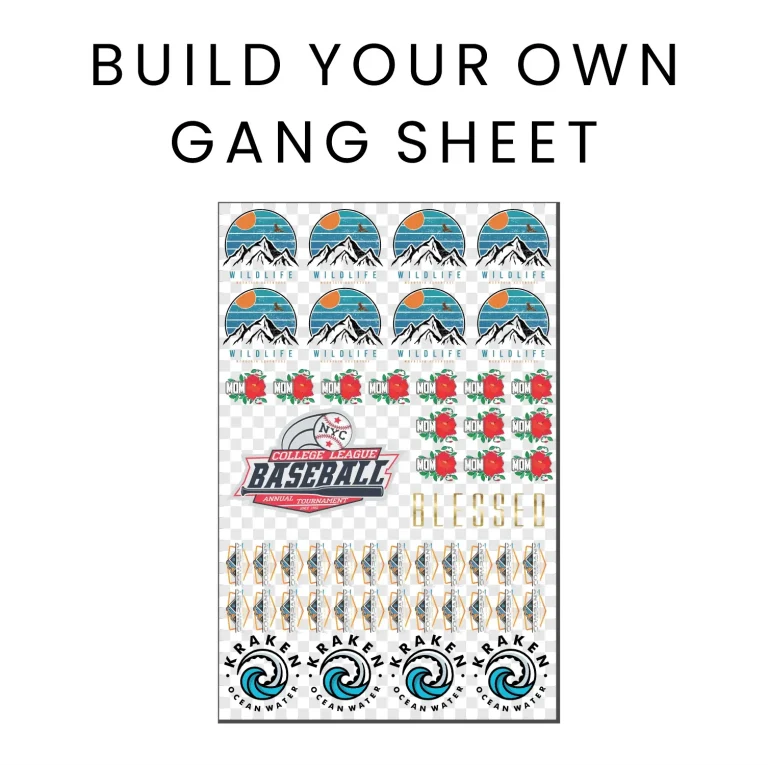

The DTF gangsheet builder is a powerful tool that streamlines multi-design transfers, and this DTF gangsheet builder tutorial will guide you from setup to production. You’ll learn how to create gang sheets DTF efficiently by arranging multiple designs on a single sheet, maximizing space and reducing waste. Master the DTF printing workflow from design preparation to heat-transfer finishing to ensure consistent results. When planning, pay attention to gang sheet design for DTF principles like margins, bleeds, alignment, and color separation so every design prints true. Choosing the right DTF software to manage layouts, color profiles, and exports will keep your production smooth and scalable.

In practical terms, think of a gang sheet as a planning canvas that combines several designs into one print-ready file, aligned with DTF printing workflow concepts. From an LSI perspective, related terms include layout automation, template libraries, color management, and precise alignment to ensure consistency across fabrics, including gang sheet design for DTF considerations. This framing emphasizes bleed, safe zones, and channel management to create scalable, reusable designs that save time on future runs, especially when paired with DTF software. You’ll encounter references to print-ready compositions, sequencing, and software-assisted layouts that map to the same production workflow you use for single designs, as highlighted in a DTF gangsheet builder tutorial. When evaluating tools, look for printer compatibility, export options, and robust color profiles to reproduce high-quality results across materials, and this approach informs how to create gang sheets DTF efficiently.

DTF Gangsheet Builder and the Printing Workflow: From Design to Delivery

DTF gangsheet builder acts as the core of a streamlined printing workflow, letting you lay out multiple designs on a single transfer sheet. By planning spacing, margins, color channels, and white ink layers within a single file, you reduce waste and ensure consistent color reproduction across designs. In the context of DTF software, a well-tuned gangsheet builder helps align artboards, manage bleed, and preview how the sheet will trim, making the DTF printing workflow more predictable from file creation to final transfer.

For beginners, exploring a DTF gangsheet builder tutorial can be a quick way to learn how to create gang sheets DTF. Start with choosing a user-friendly DTF software or plugin, define your sheet size, then import designs and arrange them in a grid (2×2 or 3×3). Use a color-management preset to match ICC profiles, and save a preset to reuse layouts for future runs. This approach aligns with how to create gang sheets DTF and helps you ramp up faster while minimizing misalignment.

Gang Sheet Design for DTF: Best Practices with DTF Software

Designing effective gang sheets for DTF requires attention to margins, safe zones, and legible typography across multiple designs on one sheet. Keep a consistent color depth and finish so every design reads similarly when printed, and use DTF software to enforce these rules with grid layouts, bleed settings, and transparent backgrounds where needed. Proper gang sheet design for DTF also means planning for white ink underlays and correct color channel order so the final transfer looks cohesive on various fabrics.

To optimize production, adopt templates and automation within your DTF software, test print small gang sheets, and practice a color-first design approach. Vectorize raster elements where possible to preserve sharp edges when scaling across sheet sizes, and document your settings for repeatable results. Integrating these practices into the DTF printing workflow minimizes misregistration, reduces waste, and speeds up multi-design runs.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it fit into a typical DTF printing workflow?

A DTF gangsheet builder is software or a workflow that arranges multiple designs on a single transfer sheet. It helps you set canvas size, margins, color profiles, and export print-ready files for production. In a DTF printing workflow, use it to grid designs (2×2, 3×3), preview alignment, and generate the final sheet. For learning, follow a DTF gangsheet builder tutorial and explore compatible DTF software for your printer.

What should I consider when designing a gang sheet for DTF using a gang sheet design for DTF approach, and how can a DTF gangsheet builder help?

When designing a gang sheet for DTF, consider consistent color depth, bleed, safe zones, and even spacing to prevent trimming issues. Use calibrated color profiles, ensure text readability, and plan the print order and underlays if needed. A DTF gangsheet builder provides grid-based placement, snapping, and preview tools, plus export formats that match your workflow, helping you execute a clean gang sheet design for DTF.

| Topic | Key Points |

|---|---|

| DTF gangsheet builder | Software or workflow to arrange multiple designs on a single transfer sheet, manage spacing, margins, color profiles, and file exports for production. |

| Gangsheet concept | A gangsheet holds multiple designs in one transfer sheet to print at once, reducing waste, speeding production, and enabling testing of options. |

| Prerequisites | DTF printer with compatible ink, film, and heater; gangsheet software; export formats (PNG with alpha, TIFF, or native); high-quality assets; calibrated color management; a simple workflow plan. |

| Step 1 – Choose tool | Look for an intuitive interface, grid-based placement, reliable export options; preview the finished sheet. |

| Step 2 – Canvas and sheet specs | Define sheet size, margins, bleed, safe zones; enable a grid; use color management presets aligned to printer ICC profile. |

| Step 3 – Import and arrange | Import designs as PNGs or vectors; place with consistent spacing; start with simple grids (2×2 or 3×3); include colorways on the same sheet. |

| Step 4 – Review and export | Preview for edge margins; verify white underlays and color channel order; export print-ready file; save presets for reuse. |

| Design and layout considerations | Maintain consistency across designs, calibrate color with ICC profiles, manage bleed and safe zones, preserve transparency, ensure text readability. |

| Printing workflow and tips | Plan print order (underlays first if needed); verify print quality; test substrate compatibility; set heat press parameters; allow curing. |

| Common mistakes | Rushing layouts; overloading sheets; ignoring color management; inconsistent file naming; skipping test prints. |

| Advanced tips | Automation and templates; vector optimization; channel management; color-first design; documentation and version control. |

| Beginner benefits | Saves time, reduces waste, provides structure, scalability, and templates that build confidence. |

Summary

DTF gangsheet builder is a powerful tool for organizing multiple designs on a single transfer sheet, enabling faster production and more consistent results. By using a dedicated layout tool, you can optimize spacing, margins, color management, and file exports, reducing waste and touchpoints throughout the workflow. Start with a clear plan for sheet sizes and safe zones, calibrate colors with ICC profiles, and run test gang sheets before full production. As you gain experience, templates and automation can further speed up repetitive tasks, helping you deliver high-quality multi-design transfers for diverse fabrics and outfits.