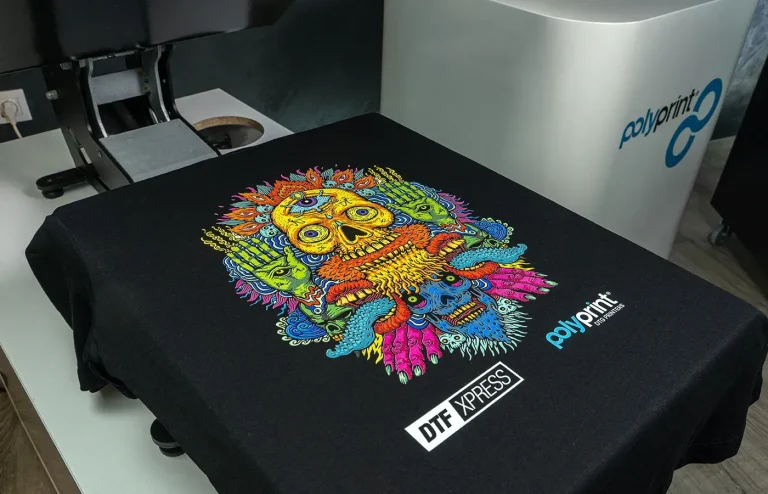

The DTF Gangsheet Builder is an essential tool for anyone delving into the world of DTF (Direct to Film) printing. This innovative solution is designed to optimize the printing process, allowing custom apparel creators to maximize the efficiency of their prints. With DTF transfer techniques, users can achieve vibrant colors and durable designs that breathe life into their projects. If you’re seeking the best results DTF, understanding how to effectively utilize the DTF Gangsheet Builder will make a significant difference. In this article, we’ll share invaluable DTF printing tips and highlight how this powerful tool can elevate your custom apparel printing endeavors.

Exploring the realm of DTF (Direct to Film) printing opens up a variety of possibilities for designers and printers alike. The DTF Gangsheet Builder serves as a pivotal component, allowing users to streamline their artwork and optimize print layouts. As you dive into different techniques for transferring designs onto fabrics, appreciating the nuances of this software becomes key to achieving striking and long-lasting results. Additionally, mastering the intricacies of custom garment printing can set you apart in a competitive market. This guide aims to illuminate the essential concepts and practices for utilizing DTF technology effectively.

Maximizing Results with the DTF Gangsheet Builder

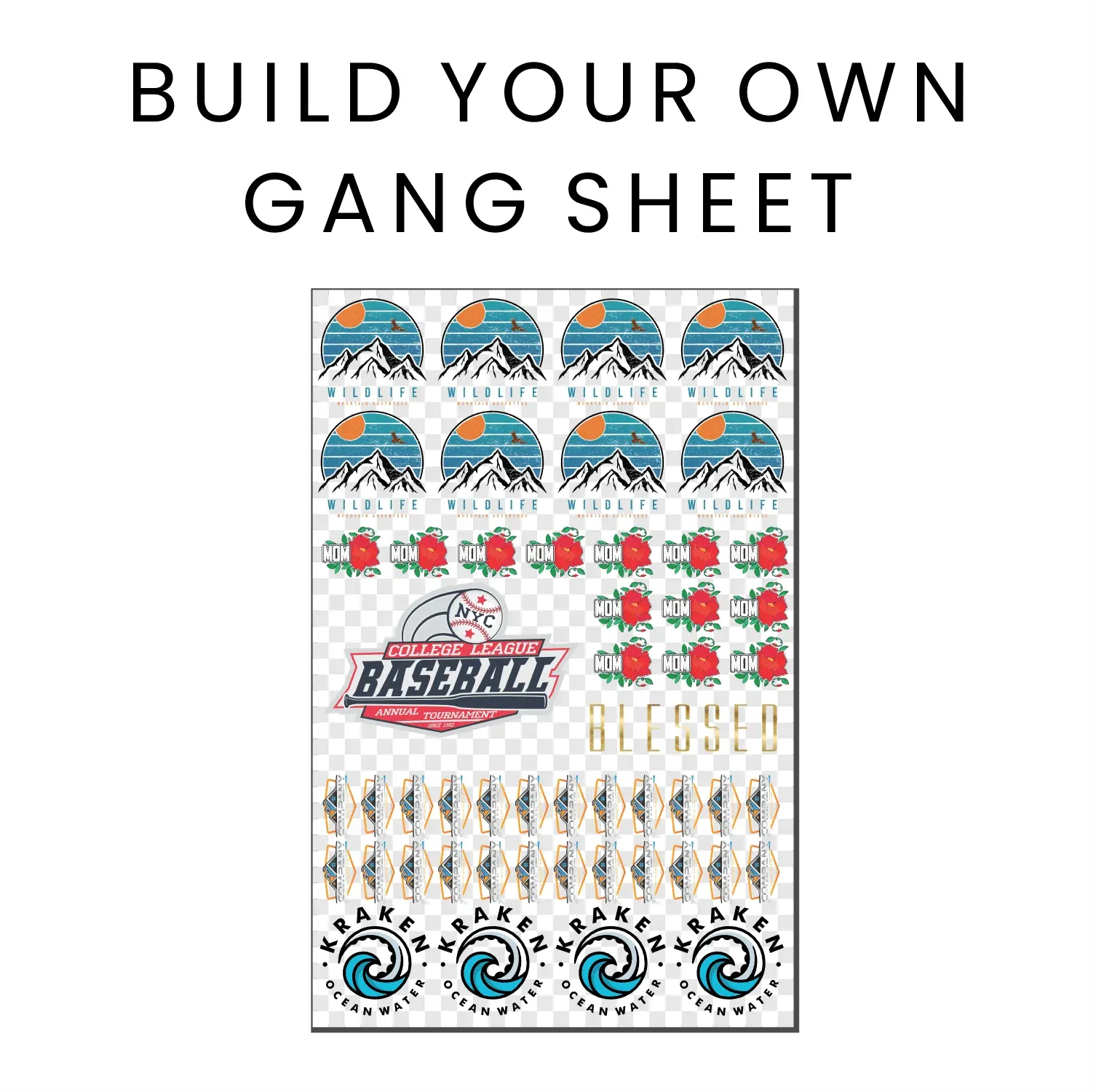

The DTF Gangsheet Builder is a powerful tool that enables users to create compact and efficient layouts for their designs, optimizing the use of film and reducing waste. By leveraging this feature, custom apparel printers can arrange multiple designs on one gangsheet, which not only facilitates large orders but also minimizes costs. The software allows for precise placement, making it easier to keep designs aligned and organized, ensuring that each transfer comes out as expected. This control over layout not only enhances operational efficiency but also guarantees vibrant prints that maintain color fidelity.

In utilizing the DTF Gangsheet Builder, users must focus on spacing between designs to prevent overlapping during the transfer process. Properly spaced designs ensure that each print receives proper heat and pressure for optimal adhesion. Moreover, experimenting with different arrangements can lead to discovering unconventional layouts that cater to specific client requests. Taking advantage of these features will help achieve the best results DTF enthusiasts can hope for, making it an essential step in the DTF printing workflow.

Understanding DTF Transfer Techniques

DTF transfer techniques are critical to achieving professional-looking prints in custom apparel. This method employs heat and pressure to transfer designs directly from DTF film to fabric, creating durable and vibrant artworks. One of the key techniques involves ensuring the right temperature is achieved during the transfer. Typically, temperatures between 320°F and 340°F are ideal, but it’s essential to adapt this based on the specific DTF inks and fabrics used. Keeping an eye on the settings not only maximizes the adhesion but also preserves the design’s integrity.

Another part of mastering DTF transfer techniques is the choice of transfer powder. The powder is crucial in binding the ink to the film, allowing it to stick to the fabric during the heat application. It’s advisable to select a powder that matches the fabric type for best results. In addition, the application technique must be precise—an even layer of powder ensures uniform results. Engaging in thorough preparation, such as preheating both the heat press and the fabric, can significantly enhance the transfer quality and overall look of the apparel.

Essential DTF Printing Tips for Success

For anyone looking to break into the world of DTF printing, grasping some core DTF printing tips can make a world of difference. Start by ensuring all designs are rendered at a high resolution; ideally, formats should be at 300 DPI or higher. Designing with high resolution allows for intricate details to shine through on the final product, maintaining crisp lines and vibrant colors that are essential for eye-catching apparel. This attention to detail is a hallmark of quality that customers will appreciate.

Additionally, understanding the importance of regular printer maintenance can prevent unexpected printing hiccups. Frequent cleaning of the printheads and ensuring the ink supply remains optimal are simple steps that deeply impact the output quality. Also, consider performing test prints before executing a large bulk job to fine-tune settings and evaluate the results. This practice can save time and costs down the line, ensuring satisfaction with each printed garment.

Choosing the Right Materials for DTF Printing

Selecting appropriate materials is fundamental to achieving great prints with the DTF process. The quality of DTF inks you use can significantly affect the vibrancy and longevity of the finished products. Investing in premium DTF inks helps prevent issues such as fading or smudging over time, ensuring that your customers receive durable products. Coupled with the right choice of DTF films, printers can produce breathtaking designs that withstand their intended use.

Moreover, it’s crucial to consider the properties of various textile substrates when selecting materials. Different fabrics react uniquely to DTF printing, and some may require special formulations of film or ink. For instance, cotton, polyester, and blends may need varying temperature and pressure settings during the transfer process. Familiarizing yourself with the characteristics of each material allows for enhanced adaptability, ensuring the prints adhere correctly and showcase true colors.

Optimizing Your DTF Design Layout

When it comes to DTF printing, optimizing your design layout can vastly improve your efficiency and output quality. Begin by making sure your designs are grouped logically on the gangsheet, utilizing all available space wisely. This not only reduces material wastage but also increases the number of designs transferred simultaneously. A well-organized layout facilitates quicker production times while also allowing for experimental designs to find their best arrangement.

However, layout optimization doesn’t just stop at arrangement; it also encompasses padding and spacing between designs. Aim for a balance that gives each design its breathing room without risking overlap during the transfer. Taking time to refine your layout will minimize distractions during the setup process and lead to a more streamlined operation. Properly executed designs will shine through, highlighting the spectacular capabilities of DTF printing techniques.

Post-Transfer Care and Maintenance of DTF Prints

Once the thrilling process of transferring designs via DTF printing is complete, it’s vital to educate customers on post-transfer care to ensure the longevity of the prints. Advising them to wash garments in cold water and to avoid harsh chemicals helps maintain the printed designs’ durability. Furthermore, recommend air drying instead of using a dryer, as heat can compromise the print quality over time. This level of customer care will foster loyalty as customers recognize that you value their experience even after the purchase.

Additionally, maintaining the heat press and printer used for DTF transfers is essential for long-term success. Regular maintenance checks and prompt address of any malfunctions can prevent potential downtimes and ensure consistent quality production. Keeping equipment in top condition directly results in fewer misprints and enhances the overall efficiency of your DTF printing operation.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a tool that allows users to efficiently layout multiple designs on a single film sheet for DTF printing. By optimizing the arrangement of designs, users can save materials and reduce costs while harnessing the vibrant colors and durability of DTF printing. This technique is key to achieving the best results in custom apparel printing.

What materials are essential for optimal DTF printing with the Gangsheet Builder?

To achieve the best results in DTF printing using the Gangsheet Builder, it is crucial to select high-quality DTF inks, specially designed DTF films, and the appropriate transfer powder. These materials ensure vibrant colors, effective adhesion to fabrics, and ultimately lead to stunning results in your custom apparel projects.

What are some best practices for using the DTF Gangsheet Builder effectively?

To use the DTF Gangsheet Builder effectively, ensure you design at a high resolution (at least 300 DPI) for crisp details, optimize the layouts to maximize film usage, and group similar designs accurately. Additionally, testing print settings and performing test prints will help refine your process and guarantee the highest quality in your DTF transfers.

How can I ensure successful DTF printing results with the Gangsheet Builder?

Successful DTF printing results with the Gangsheet Builder hinge on several factors: choose high-quality materials, maintain the printer properly, and adjust printer settings according to the type of DTF film and ink used. Adequate pressure during transfer and following proper cooling and peeling techniques also play vital roles in achieving flawless prints.

What are key DTF printing tips to remember when using the Gangsheet Builder?

Key DTF printing tips when using the Gangsheet Builder include: 1) Always preheat your heat press for effective transfer, 2) Use the right pressure settings to ensure adhesion, and 3) Advise customers on post-transfer care such as washing instructions to maintain print quality. Following these can enhance the longevity and appearance of your designs.

Can the DTF Gangsheet Builder be used for complex designs and multiple colors?

Yes, the DTF Gangsheet Builder is particularly suited for complex designs with multiple colors. The DTF printing technology excels in capturing intricate details, making it a popular choice for custom apparel. By using the Gangsheet Builder effectively, you can maximize color vibrancy while minimizing material waste, ensuring beautiful outcomes in all your projects.

| Key Point | Details |

|---|---|

| Introduction to DTF Gangsheet Builder | DTF printing provides vibrant colors, durability, and is essential for custom apparel. |

| Understanding DTF Technology | Printing onto a release film that transfers designs to textiles using heat. |

| Choosing the Right Materials | Select high-quality DTF inks, films, and transfer powders for best results. |

| Design Optimization | Design at high resolution and arrange multiple designs efficiently on a gangsheet. |

| Printer Settings | Adjust printer settings and maintain the printer for optimal performance. |

| Transfer Process | Preheat press, apply adequate pressure, and peel after cooling. |

| Testing Your Process | Conduct test prints to ensure quality before large orders. |

| Post-Transfer Care | Advise customers on proper care and washing instructions for longevity. |

Summary

The DTF Gangsheet Builder is a game-changer for anyone looking to enhance their printing capabilities. By mastering the intricacies of DTF printing—from understanding the underlying technology to selecting the right materials and perfecting the transfer process—you can ensure that your designs stand out and are built to last. It’s crucial to implement effective design optimization techniques and regular printer maintenance to achieve consistently high-quality outputs. Testing your process meticulously will help you fine-tune your approach and build customer satisfaction. Following up with proper care instructions will further ensure that your prints remain vibrant and durable, solidifying your reputation in the competitive world of custom apparel printing. Embrace these strategies with the DTF Gangsheet Builder, and you’ll be well on your way to creating impressive prints that wow your customers.