Direct-to-Film Printing is redefining how designers and print shops approach apparel decoration, blending digital design with a simple transfer process to unlock vibrant, durable results, while offering a flexible workflow that suits both boutique studios and larger production spaces. This approach relies on a reliable DTF printer and compatible DTF inks to create bold colors on a wide range of fabrics, from cotton tees to performance blends, with rich saturation, smooth gradients, and a forgiving print path that reduces misregistration. A clear transfer film carries the design, then a fine adhesive powder for DTF is applied and cured to form a strong bond before heat pressing, ensuring the ink sits on or near the fabric surface for lasting vibrancy and wash durability. With the right DTF supplies, including transfer film, adhesive powder for DTF, curing equipment, a reliable heat press, and quality RIP software, you can streamline small-batch production, maintain consistent results across runs, and scale up as demand grows. As a versatile solution for makers, brands, and small studios, DTF technology continues to evolve with improved white underlays, faster curing options, and better color management, helping you deliver professional-looking transfers quickly and with fewer production bottlenecks for e-commerce drops, event branding, and on-demand orders.

Direct-to-Film Printing: A Practical Guide to DTF Supplies and Workflow

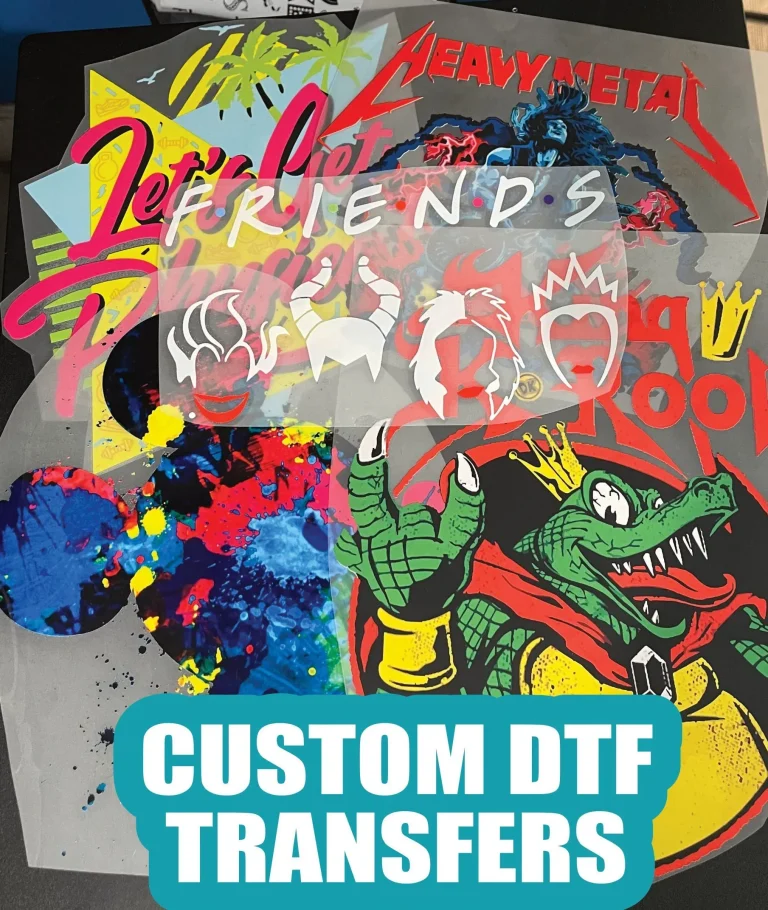

Direct-to-Film Printing redefines how designers and print shops decorate apparel by combining digital imaging with a simple transfer process. In this workflow, a design is printed in reverse onto a transparent transfer film using DTF inks, a white base layer on dark fabrics, followed by a coating of adhesive powder and a curing step before heat pressing onto the garment. This approach creates vibrant, durable transfers with a soft hand feel across a wide range of fabrics.

The DTF printer serves as the backbone of the setup, delivering color-rich output that leverages white ink for dark textiles and high-opacity color inks for bright gradients. With the right transfer film and adhesive powder for DTF, you can achieve reliable adhesion and clean releases, reducing misprints and powder shedding while keeping workflow relatively straightforward for small runs.

In practice, this means you can scale from home studios to small commercial shops without paying for expensive screens. The essential DTF supplies—from the DTF printer and DTF inks to transfer film and curing equipment—work together to deliver consistent results when proper color management and maintenance practices are followed.

DTF Supplies: Best Practices for Consistent, High-Quality Transfers

Choosing the right DTF supplies is critical to reliability. A compatible DTF printer paired with robust DTF inks (including a white ink layer for dark fabrics) and a suitable transfer film determines color density, detail retention, and wash durability. Paying attention to the ink compatibility with your printer and film ensures predictable results and easier RIP-based color management.

Equally important are the adhesive powders for DTF and the curing process. A uniform, thin powder coat that is properly cured improves powder adhesion, reduces shedding, and promotes a durable bond during heat pressing. Selecting a compatible transfer film with the chosen printer and inks, along with reliable curing or drying equipment, underpins a stable, repeatable workflow.

Additional best practices include maintaining RIP software profiles for consistent color, regular printer maintenance, and proper storage of transfer films and powders to prevent moisture uptake. Together, these steps help minimize color drift and defects, delivering consistent results across batches.

Frequently Asked Questions

What are the essential DTF supplies for Direct-to-Film Printing, and how do the DTF printer, DTF inks, transfer film, and adhesive powder work together?

Direct-to-Film Printing relies on a core set of supplies that work in harmony. The essential DTF supplies include a DTF printer, DTF inks (white and color inks), transfer film, adhesive powder for DTF, curing or drying equipment, a quality heat press, RIP software for color management, and basic maintenance tools. In practice, you print your design on the DTF transfer film using your DTF printer and inks (white ink is crucial for dark fabrics). After printing, you apply a thin coat of adhesive powder and cure it so the powder bonds to the ink. The film is then pressed onto the garment with a heat press, where the adhesive melts and bonds the image to the fabric. This workflow delivers vibrant transfers on many fabrics with a soft hand feel. Regular maintenance and proper storage of films and powders help sustain consistent results.

How can I optimize Direct-to-Film Printing results and troubleshoot issues related to the transfer film and adhesive powder for DTF?

To optimize Direct-to-Film Printing, select the right transfer film (consider thickness and clarity) and ensure your adhesive powder coats are uniform before curing. Use a compatible DTF printer and DTF inks, especially ensuring white ink produces solid coverage on dark fabrics. Cure the powder properly, then press at the recommended temperature, time, and pressure for your film and fabric. Use RIP software to manage color profiles and calibrate output across batches. Common issues—powder not adhering, color washing out, or cracking after wash—usually stem from incomplete curing, uneven powder application, or incorrect heat or time settings. Regular maintenance, proper film storage, and testing on sample garments help prevent these problems.

| Topic | Key Points |

|---|---|

| What Direct-to-Film Printing Is and How It Works | – Direct-to-Film Printing is a digital ink-on-film process that creates a transfer ready for fabric application. – A design is printed in reverse on DTF transfer film using specialized inks, including white ink for dark fabrics. – The printed film is coated with hot-melt adhesive powder and cured/dried so the powder sticks to the ink. – The film is pressed onto the garment with a heat press; the film fibers melt and bond to the fabric, producing a durable, colorful transfer without screens. |

| Why DTF Printing Is Gaining Traction | – Versatility: Works on a broad range of fabrics and garments, including dark and light textiles. – Color Brilliance: White ink plus high-quality inks produce bright, crisp images with smooth gradients. – Convenience: Simpler setup than traditional screen printing and shorter lead times for small runs. – Cost-Effectiveness: No need for screens for each design; good for short runs and one-offs. – Scalability: Easily grows from home studios to small commercial shops with the right supplies. |

| Essential DTF Supplies You Need (Overview) | A core toolkit that works together to deliver consistent results across fabrics and designs. |

| DTF Printer | – Backbone of the workflow; designed for dye-based or pigment inks with reliable print heads and ink circulation. – Compatible with the chosen DTF inks; some are marketed as DTF-specific, others are standard inkjets configured for DTF. – Key considerations: print head reliability, white ink support, color management, RIP compatibility, maintenance, and replacement parts. |

| DTF Inks (White and Color Inks) | – Formulated for transfer film; white ink is essential for dark fabrics. – Focus on brightness, opacity, compatibility with printer/film, print longevity, and cost per print. |

| Transfer Film (DTF Film) | – Carries the printed image; must release cleanly and retain detail after pressing. – Consider thickness (thinner for detail; thicker for forgiveness on larger runs), adhesion after curing, compatibility, and storage stability. |

| Adhesive Powder (Hot-Melt Powder) | – Bonds ink to fabric when heated. – Tips: apply a uniform, thin coat; ensure proper curing; choose powders with good wash-fastness and fabric flexibility. |

| Curing or Drying Equipment | – Needed to dry/cure the adhesive powder before pressing. – Options include a heat tunnel, heat dryer, or curing oven; aim for uniform drying without scorching. |

| Heat Press | – Provides controlled heat and pressure for bonding. – Important factors: temperature control, even pressure, transfer time, and appropriate platen size. |

| RIP Software and Color Management | – Manages color profiles and print settings for consistency across fabrics. – Look for color management, ICC profiles, tiling, and calibration tools. |

| Cleaning, Maintenance, and Miscellaneous Tools | – Keep the system clean to reduce color drift. – Store films dry and protected; check powders for moisture; have basic tools (wipers, squeegees, gloves, isopropyl alcohol) handy. |

| Design, Print, Powder, Press: Step-by-Step Workflow | – Prepare artwork with accurate color profiles. – Print onto transfer film; mirror if required. – Inspect color density; reprint if needed. – Apply adhesive powder evenly; cure/dry thoroughly. – Align on garment and press at recommended settings. – Allow to cool and peel; adjust parameters if needed. |

| Common Issues and Troubleshooting | – Off-white colors: check white ink coverage and base layer; nozzle health and alignment. – Powder not adhering: ensure proper curing and uniform application; review drying time/temperature. – Sticky surface: adjust curing or heat/time. – Cracking/peeling after wash: verify fabric compatibility and washing parameters. |

| Maintenance and Best Practices | – Regularly clean printer heads and maintain alignment. – Store transfer films in a dry, clean area; replace powders showing moisture or clumps. – Calibrate RIP profiles periodically for color accuracy across batches. – Test on new fabrics/films before full runs. |

| DTF in Practice: Use Cases and Considerations | – Well-suited for small-batch runs, on-demand printing, and customized merchandise. – Excels with bright, saturated colors on a variety of fabrics without separate color screens. |

Summary

HTML table generated summarizing the key points of the base content in English.