DTF gangsheet builder software transforms how shops print by maximizing each sheet’s usable area and reducing waste. It supports improved DTF printing efficiency and gangsheet layout optimization to minimize waste. By previewing layouts and margins, it helps reduce misprints DTF during production. The tool also enables DTF ink savings by controlling ink coverage and color management. Whether you run a small shop or a larger studio, the gangsheet builder tool integrates smoothly into your workflow.

Beyond the direct tool talk, this approach aligns with smart garment-decoration workflows that emphasize sheet intelligence and automated tiling. Think of it as a gangsheet optimization engine that coordinates design placement, margins, bleed, and color fidelity across multiple jobs. The concept resonates with production planning, prepress automation, and error reduction. In practice, teams leverage layout-aware software to streamline prepress, minimize waste, and ensure consistent results on textiles and other substrates. By adopting this mindset, studios can scale throughput while maintaining accuracy, regardless of order complexity.

Maximizing DTF Printing Efficiency with a DTF gangsheet builder

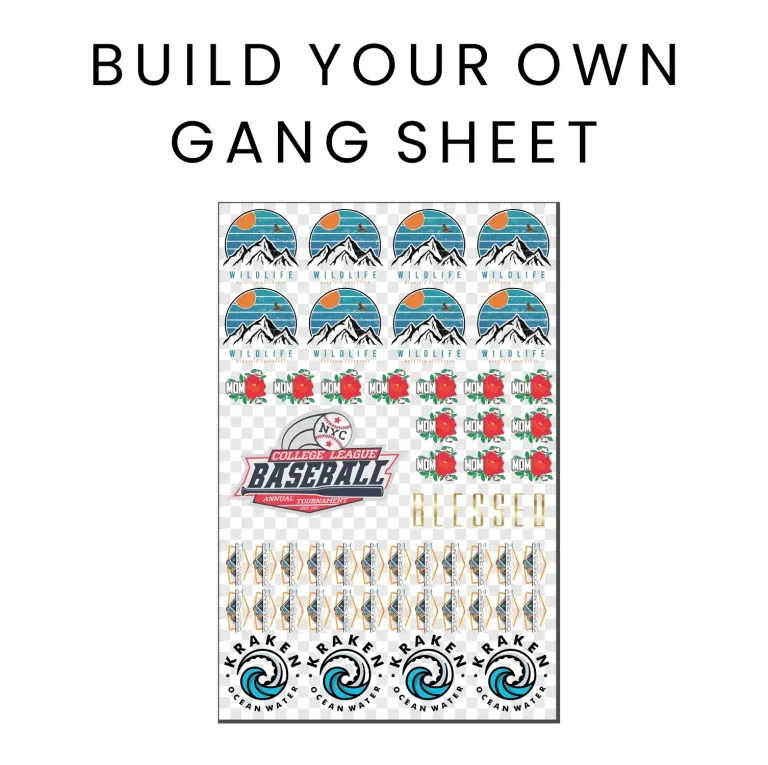

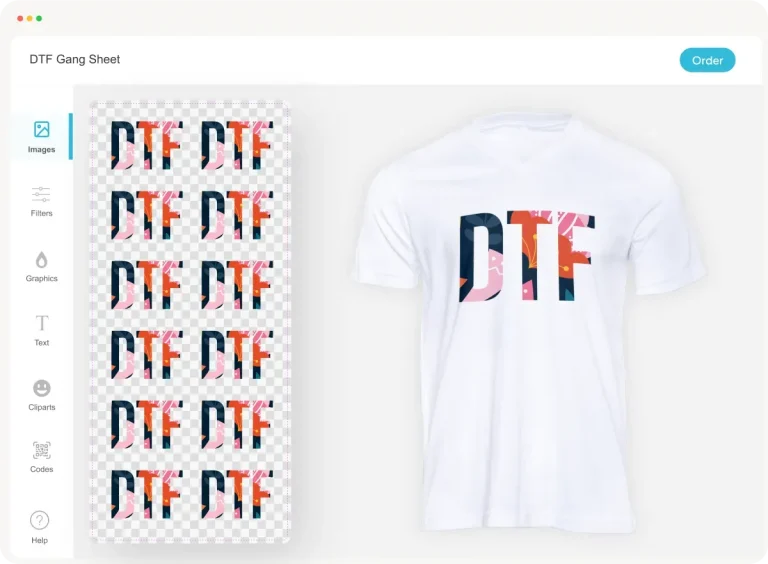

A DTF gangsheet builder is software that arranges multiple designs on a single printable sheet in a way that minimizes wasted space and ink. By orchestrating layout decisions with margins, bleeds, rotation, and mirroring options, it directly supports superior DTF printing efficiency and gangsheet layout optimization. This tool helps you visualize how designs will render when printed, ensuring that the available print area is used to its fullest, which translates to more garments or substrates decorated per run without sacrificing image quality.

Beyond simply tiling, a capable DTF gangsheet builder standardizes print preparation so you can reduce misprints DTF and maintain consistent color across designs and devices. With precise bleed control, safe zones, and reliable previews, you prevent color shifts and alignment errors before a single sheet goes to the RIP. The result is not only faster production but also tangible benefits like DTF ink savings and a more predictable workflow that scales from a small shop to a high-volume print studio, all while keeping image fidelity intact.

Practical guide to implementing a DTF gangsheet builder for color consistency and ink savings

To start, gather all designs destined for the same gangsheet and prepare them at a suitable resolution with consistent color profiles. The gangsheet builder allows you to set sheet size and print area, then apply margins and bleeds that prevent edge artifacts. By focusing on gangsheet layout optimization during setup, you ensure that each design occupies optimal space and that the final output maintains color accuracy across the entire sheet.

As you arrange layouts with automatic tiling, rotation, and alignment aids, preview the color output and calibrate ink usage to minimize waste. Export print-ready files that preserve the intended color profile and bleed settings, and integrate them into your RIP workflow. Through standardized templates, consistent file formats, and diligent performance tracking, you’ll realize improvements in DTF printing efficiency, substantial DTF ink savings, and fewer misprints, all achieved by leveraging the consistent capabilities of a robust gangsheet builder tool.

Frequently Asked Questions

How does a DTF gangsheet builder improve DTF printing efficiency and reduce misprints?

A DTF gangsheet builder maximizes sheet usage through smart tiling, margins, and bleeds, boosting DTF printing efficiency by reducing wasted space and the number of sheets needed. It also provides previews and alignment checks that cut misprints, ensuring consistent color and margins across designs. Together, these features streamline production and improve DTF ink savings.

Which features in a gangsheet builder tool support gangsheet layout optimization and DTF ink savings?

Look for auto-tiling, rotation, mirroring, and alignment guides in a gangsheet builder tool to optimize gangsheet layout and density. Strong color management, bleed control, and accurate print area visualization help standardize ink coverage, delivering DTF ink savings and more predictable results across designs and jobs.

| Aspect | Key Points |

|---|---|

| Purpose | A DTF gangsheet builder arranges multiple designs on a single printable sheet to maximize area, reduce waste, and streamline multi-design runs. |

| Ink Efficiency & Misprints | By minimizing blank space and standardizing margins, bleeds, and color management, it lowers ink usage and reduces misprints caused by cropping or color shifts. |

| Core Benefits | Increased efficiency, lower ink costs, fewer misprints, and faster production. |

| Key Features | Automatic tiling, rotation/mirroring, print area visualization, safe zones, and color calibration previews. |

| How to Use (Overview) | Gather designs, choose sheet size, set margins/bleeds, arrange layouts, preview color management, and export for production. |

| Color Management | Supports consistent color profiles across designs and printers to minimize color shifts and test prints. |

| Practical Tips | Standardize templates, use consistent file formats/profiles, leverage rotation/mirroring, run mockups, plan post-processing, track metrics. |

| Impact & Case Studies | Real-world results include reduced sheet waste, lower ink usage, and fewer misprints, improving turnarounds. |

| Choosing a Builder | Ease of use, intelligent layout, color management, RIP integration, and scalability. |

Summary

DTF gangsheet builder is a strategic tool that directly influences ink efficiency, cost per print, and misprint reduction by optimizing how designs are laid out on each sheet. By standardizing margins, bleeds, and color management, it enables reliable previews and a more predictable production workflow. Whether you run a small shop or a high-volume studio, adopting a gangsheet approach can lower material costs, speed up turnarounds, and improve consistency across orders. Start with clear requirements, test layouts on real jobs, and measure the impact on key metrics to build a repeatable, efficient workflow that consistently delivers high-quality results for your customers.