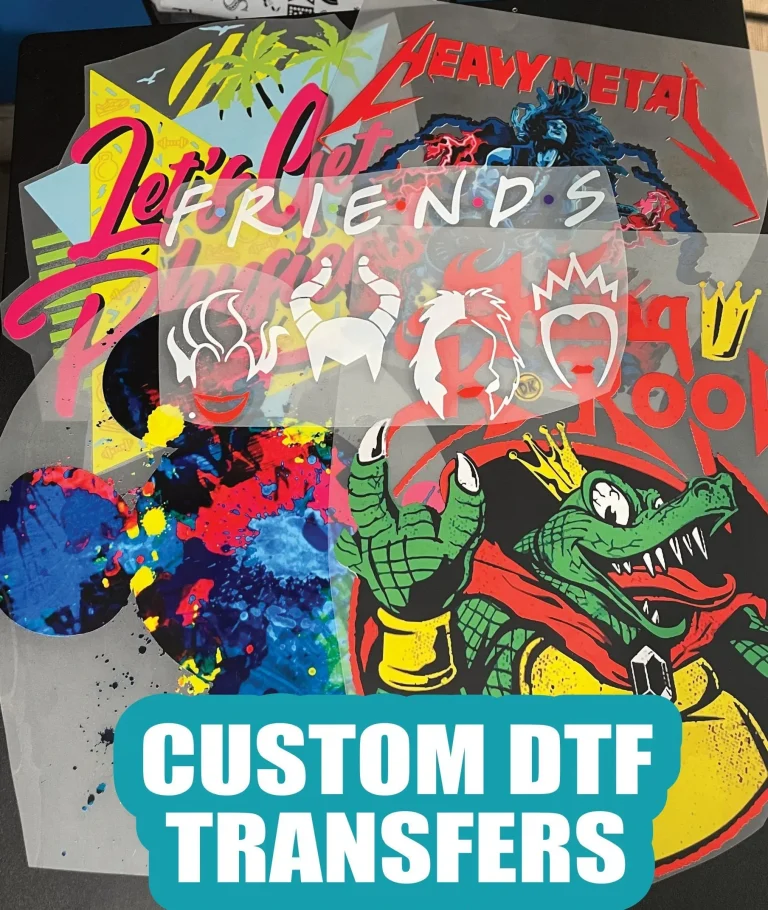

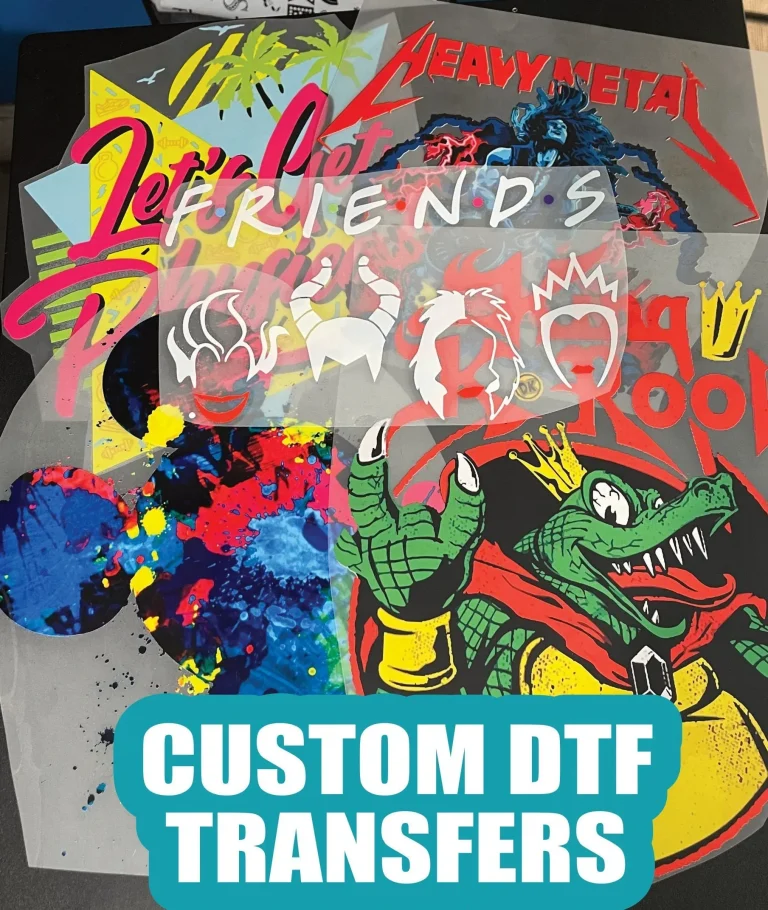

DTF transfers have transformed apparel decoration by delivering vibrant color, broad fabric compatibility across cotton, blends, and even certain synthetics, and a forgiving workflow that supports small runs, on-demand production, and the ability to batch designs for future releases. If you’re starting out, this guide explains the DTF workflow in practical terms, highlighting the DTF equipment you’ll need, from reliable printers and films to curing gear, and how each component contributes to consistent, durable results. You’ll learn about the core steps from artwork preparation and color separation to printing on the PET transfer film, powder adhesion, curing, and the transfer itself, with emphasis on ensuring white ink opacity on darker fabrics, color management strategies, and practical checks to prevent misregistration during pressing. Practical tips cover printable material quality, printer maintenance, color management, profile calibration, substrate testing, and the interplay of temperature, time, and pressure to achieve consistent adhesion without scorching or cracking, plus guidance on onboarding clients and documenting best practices for repeatable results. By planning ahead, calibrating your workflow, and running batch tests, you’ll have a solid foundation to plan a DTF project or business with confidence, including how to scale capacity, manage customer expectations, and iterate your products based on feedback.

Direct-to-film design and transfer—often described as film-based textile printing—approaches garment decoration from a slightly different perspective. Instead of talking only about a heat-transfer film, think of a digital art piece printed onto a release sheet that is later bonded to fabric with heat and pressure. This framing highlights related concepts such as substrate versatility, color-fast results, and careful curing and post-press care. Whether comparing this approach to DTG, screen printing, or other ink-on-fabric workflows, the underlying principles apply across fabrics, colors, and production scales.

DTF transfers: How the DTF printing process, materials, and equipment come together

DTF transfers have transformed textile decoration by enabling vibrant color, fabric versatility, and a flexible workflow. To understand why, it helps to look at the DTF printing process as a chain: design preparation, printing on a PET transfer film using white ink plus CMYK, powder adhesion, curing, and finally a heat-press transfer to fabric. Grasping how DTF works starts with the printing stage, the transfer materials, and the essential DTF equipment that makes consistent results possible.

DTF transfer materials include the transparent PET film, water-based CMYK inks with white for opacity on dark fabrics, adhesive powder, shakers or sifters, curing units or hot air dryers, and a reliable heat press. The DTF equipment you choose—such as a printer compatible with white ink, a dedicated curing setup, and a sturdy heat press—directly affects color accuracy, adhesion, and throughput. Investing in quality components helps minimize issues and sustains long-term durability.

A standard DTF workflow follows a repeatable sequence: color-managed design, printing on film, powder application and curing, removal of excess powder, and transfer to the garment with heat and pressure. Proper prepress color management and precise curing are critical to prevent misregistration and ensure wash-fast results. This method works across cotton, blends, polyester, and dark fabrics, making it a versatile option for on-demand production.

With the right approach to DTF transfers, you can batch multiple transfers and store them before pressing, supporting small runs and scalable workflows. This flexibility—combined with the DTF printing process and compatible materials and equipment—helps both hobbyists and professional shops achieve reliable, high-quality results.

DTF transfer vs screen printing and DTG: How to choose the right method for fabrics and runs

DTF transfer vs screen printing: For small runs and designs with complex color gradients, DTF transfers often require less setup and can deliver vibrant multi-color images on a wide range of fabrics, including dark textiles. Screen printing excels in high-volume production but needs screens, separations, and setup for each color. By weighing factors like the DTF transfer materials and equipment against screen printing constraints, shops can decide which method yields the best balance of cost, speed, and design fidelity.

DTF transfer vs DTG: Direct-to-garment printing (DTG) can produce very smooth results directly on fabric, but may struggle on dark fabrics without a white underbase. DTF transfers use a white ink layer on the PET film to achieve opacity and color lift on dark fabrics, with strong wash durability and typically lower per-unit costs for small runs. This makes DTF advantageous for non-cotton fabrics, bold color work, and on-demand orders while maintaining image sharpness.

Practical selection guidelines include considering fabric type, color complexity, run length, budget, and desired hand feel. Conduct side-by-side tests of the DTF printing process and DTG or screen printing to evaluate color fidelity, stretch, and durability. Use color management tools, ICC profiles, and manufacturer guidelines to ensure the chosen method aligns with your equipment and production goals.

Frequently Asked Questions

How does the DTF printing process work for DTF transfers?

The DTF printing process starts with design prep and color management, then prints the artwork onto a PET transfer film using white ink and CMYK inks on a DTF-compatible printer. After printing, a fine adhesive powder is applied and cured, and excess powder is removed. The film is placed on the garment and heat pressed to transfer the design, with a possible post-press for full adhesion. DTF transfer materials include PET film, water-based inks (white and CMYK), adhesive powder, a curing unit, and a heat press. This method works on a wide range of fabrics, including cotton, blends, and dark textiles, delivering durable, vibrant results.

DTF transfer vs screen printing: when should you choose DTF transfers over screen printing?

DTF transfers are typically ideal for short runs and on-demand production because they require less setup and can handle complex color gradients on many fabrics, including darks. Screen printing is usually more economical for large-volume orders and best for designs with fewer colors after screens are prepared. DTF transfers work across a broader fabric range and can simplify color limitations, while screen printing can offer very high throughput for simple, multi-color designs. Choose DTF transfers for small runs or custom designs, and choose screen printing for large batches and simpler color work.

| Aspect | Key Points |

|---|---|

| What are DTF transfers? | DTF transfers are a modern textile printing method where a color design is printed onto a PET film using water-based inks (including white). After printing, a powdered adhesive is applied and cured, and the film is heat-pressed to the garment to create a durable, vibrant image on fabrics such as cotton, polyester, blends, and dark textiles. The film format allows batching multiple transfers for small runs or on-demand production. |

| The DTF transfer process – Step-by-step | 1) Design and prep: artwork in vector or high-res raster with layers for colors (especially white); color-managed and sized for the garment area. 2) Printing on PET film: print with a DTF printer using white + CMYK inks; white is crucial for opacity on dark fabrics. 3) Powder application and curing: dust adhesive powder while the ink is wet and cure to set the powder. 4) Removal of excess powder: brush/blow away excess powder after curing. 5) Transfer to fabric: place film on garment with printed side down; heat press to bond; peel away film. 6) Post-press if needed: optional secondary press for adhesion and wash durability. |

| Materials needed | DTF film (transparent PET); water-based CMYK inks plus white; powder adhesive; powder shaker; curing unit or hot air dryer; heat press; weeding tools and protective liners; cleaning supplies and safety gear. |

| The role of the DTF printer and equipment | DTF printers handle white ink and multi-color CMYK on film and must work with the adhesive powder workflow and curing temperatures. Beyond the printer, a dedicated heat press is essential; some shops use a conveyor dryer or hot air ovens for powder curing. Equipment choice affects efficiency, color accuracy, and throughput. |

| The DTF workflow in practice | Prepress/color management: calibrate monitors and use ICC profiles. Artwork optimization: simplify elements, ensure white layers separate, and plan for good registration. Printing and curing: print on PET film with accurate alignment and solid white areas; cure the film. Powder adhesion and curing: apply adhesive powder evenly, cure, and remove excess. Transfer and finishing: align the film on the garment, apply heat/pressure, and peel per method (hot or cold) for your system. |

| Quality control and troubleshooting | Color matching: test with swatches and rely on printer profiles. White ink opacity: ensure whites are solid, adjust profiles and viscosity if needed. Adhesion quality: cure, pressure, and temperature must be correct; check edges after washing. Film handling: avoid misalignment and wrinkling; maintain a tidy workflow. Wash durability: ensure proper curing and post-press care; advise customers on garment care. |

| DTF transfers vs other methods | DTF transfers vs screen printing: handles complex color gradients well, is often more economical for short runs, and works on a broader fabric range with forgiving color options. DTF transfers vs DTG: DTG prints directly on garments; DTF offers durability, cost advantages for small runs, and strong color lift on non-cotton or dark fabrics. |

| Best practices for successful DTF projects | Choose quality components (film, inks, powders, heat press). Calibrate and test: run scrapes to dial in temperature, pressure, and time. Follow proper press settings (temperature typically 320–380°F, 8–15 seconds, suitable pressure). Prepare fabrics (pre-wash) and provide post-care guidance. Store printed films properly and plan production batches to optimize workflow. |

| Applications and limitations | Versatile for fashion tees, hoodies, bags, and athletic wear; suitable for small to medium runs and custom orders with complex color schemes. Limitations include the tactile feel of some transfers and potential challenges with ultra-photorealistic detail on certain fabrics; always test fabrics and inks to determine best use. |