DTF transfers have revolutionized how designers, printers, and apparel brands bring graphics to life on T-shirts. This method offers vibrant color, a soft hand feel, and a workflow that scales from small runs to large productions. DTF printing and the direct-to-film transfer process enable precise edge work and full-color fidelity from concept to garment. For durability, pay attention to DTF film durability and proper curing, as these steps underpin wash-fast, crack-resistant results. If you’re comparing DTF vs screen printing or looking for practical DTF design tips, this guide helps you plan confidently.

Another way to describe this approach is a film-based transfer system that moves artwork onto fabric with heat and pressure. The workflow begins with high-quality artwork, prints it onto a specialty PET sheet, coats with adhesive powder, and cures before transfer. Compared to traditional screen printing, this method offers versatility across fabrics, strong color density, and a soft hand thanks to the thin adhesive layer. Using LSI-friendly terms like film-to-fabric transfer, heat-press application, and dye-accurate color management helps your content connect with related search queries. Keep the focus on design preparation, precise alignment, and proper curing to ensure durable, wash-ready results.

DTF transfers in Action: From Design to Durable Tees

DTF transfers represent a direct-to-film transfer process that begins with a digital design and ends on fabric through heat and pressure. In the broader field of DTF printing, the film carries the entire image, and an adhesive layer bonds the design to the garment once warmed. This approach delivers vibrant color and a soft hand feel, making it well suited for small runs and big productions alike. The workflow emphasizes accuracy in color management, precise trimming, and proper curing to maximize DTF film durability over time.

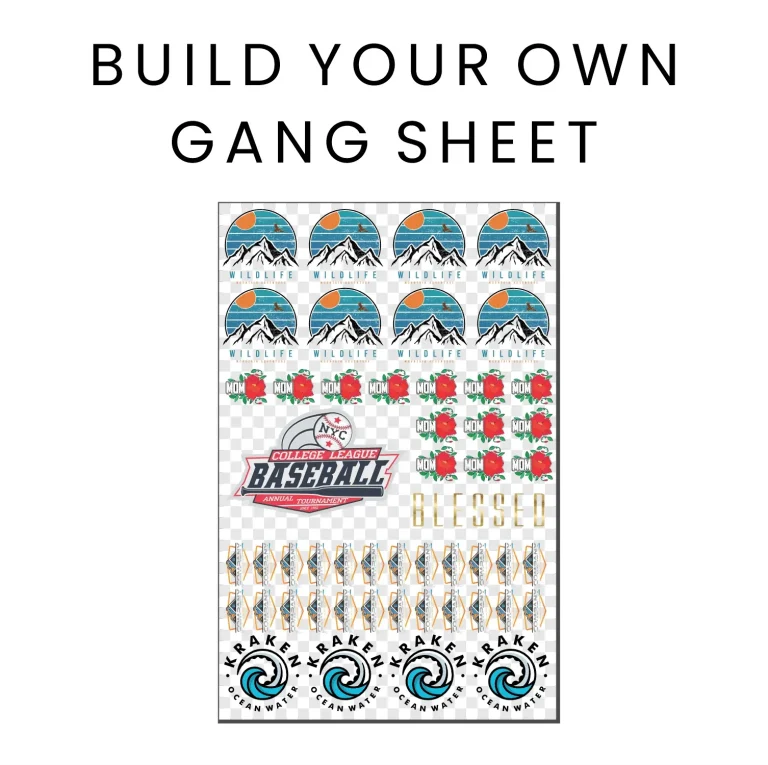

Designing for DTF requires practical tips that translate ideas from screen to fabric. For best results, work with clean vector shapes for sharp edges, or raster art at high resolution, typically 300 dpi at the final print size. Keep white space and trim lines in mind to ensure easy alignment during application, and plan color separations with attention to gradients and skin tones. A solid strategy around DTF design tips helps maintain edge clarity and color fidelity when the transfer is applied to different fabric types.

DTF Printing vs Screen Printing: Weighing Color, Durability, and Workflow

DTF printing offers distinct advantages over traditional screen printing, especially for short runs and on-demand orders. Unlike screen printing, which relies on creating screens for each color, DTF can reproduce complex, photo-realistic designs with smooth gradients directly from a digital file. This makes DTF a strong option for designs that demand full-color detail and a soft hand feel, while also enabling compatibility with a wider range of fabrics.

When considering durability and wash fastness, DTF film durability and proper curing play critical roles. The adhesive powder is cured to form a durable bond that holds up through multiple washes with care. In contrast, screen printing may excel on bold, simple designs but can feel heavier and crack over time on certain fabrics. Evaluating the production workflow—cost per unit, minimums, and speed—helps determine whether DTF printing or screen printing is the better fit for a given project.

Frequently Asked Questions

What is DTF printing and how does the direct-to-film transfer process work?

DTF printing is a direct-to-film transfer process that prints a design onto a PET film, coats the ink with an adhesive powder, cures the powder, and then transfers the image to fabric with heat and pressure. The film carries the full-color image, and when heated the adhesive bonds it to the garment, delivering a durable, vibrant print with a soft hand feel. The typical workflow includes design and color management, printing on film with water-based inks, powder coating and curing, aligning the transfer on the fabric and pressing at about 300–320°F for 15–20 seconds, followed by a cooling peel and finishing. This approach suits small runs and on-demand production and contrasts with traditional screen printing by handling full-color designs on a variety of fabrics.

How durable are DTF film transfers and what design tips help maximize longevity compared to screen printing?

DTF film durability is strong when properly cured and heat pressed, offering good wash-fastness and flexibility across many washes. To maximize longevity, follow garment care instructions (turn inside out, wash cold or warm, avoid harsh detergents, and minimize high-heat drying) and avoid excessive post-press heat. In comparison to screen printing, DTF provides full-color detail and a softer hand feel, often with excellent durability on a wide range of fabrics, though large solid-color runs can be more cost-efficient with screen printing. For durability and quality, consider these DTF design tips: use high-resolution art (300 dpi at final print size), design with clean vector shapes for sharp edges, implement careful color management (especially skin tones and gradients), and leave sufficient negative space to simplify alignment during application. Always test a sample before committing to a full run to verify adhesion, color fidelity, and hand feel.

| Section | Key Points |

|---|---|

| Introduction | DTF transfers reshape how designers, printers, and apparel brands approach custom t-shirts, offering vibrant color, soft hand feel, and a scalable workflow for both small runs and large productions. |

| Understanding DTF Transfers | DTF stands for direct to film; the process prints onto a PET film, coats it with an adhesive powder, cures the powder, and transfers the image to fabric with heat and pressure. Prints on film carry the whole image, delivering a durable, vibrant print that can stretch with the fabric and resist cracking. |

| The Direct-to-Film Transfer Process |

|

| Designing for DTF | Prepare artwork at the recommended resolution (often 300 dpi); use clean vector shapes for sharp edges; manage color separations focusing on skin tones and gradients; account for white space and trim lines for easy alignment. |

| DTF vs Screen Printing and Other Methods | • Setup and run size: DTF excels at short runs and on-demand orders due to lower setup; large runs may favor screen printing. • Color and detail: DTF reproduces complex images with smooth gradients; screen printing excels at bold, simple designs with fewer colors. • Garment compatibility: DTF works on cotton, poly blends, and many fabrics; durability varies by fabric. • Feel and durability: DTF typically has a softer hand; washes well with proper curing. • Cost and speed: DTF is quick for small runs; screen printing can be more cost-efficient per unit on large runs. |

| Materials and Equipment You Need | • DTF printed film and adhesive powder • A compatible printer with the right inks and RIP software • A heat press with stable temperature control and even pressure • A curing station or oven to cure the adhesive powder • Scissors or a cutter for trimming the film • Lint-free gloves and proper safety equipment when handling hot materials |

| Durability, Care, and Longevity | DTF prints hold up well when properly cured and heat pressed. Care: turn garments inside out, wash cold or warm, avoid harsh detergents and high tumble drying; avoid excessive heat after application; store away from direct sunlight; test a sample before full runs. |

| Troubleshooting Common DTF Issues | Cracking/peeling: ensure proper curing and correct press settings; Fading colors: calibrate printer profiles; White edges/haloing: trim precisely and ensure film sits flat; Sticky prints: allow cooling and verify film release properties. |

| Best Practices for Consistent Results | Maintain stable press temperature and pressure; use consistent curing; keep firmware, driver software, and RIP profiles up to date; maintain a QC checklist; document workflow and steps for reproducibility. |

| Conclusion | (Table row provides a concise takeaway.) |