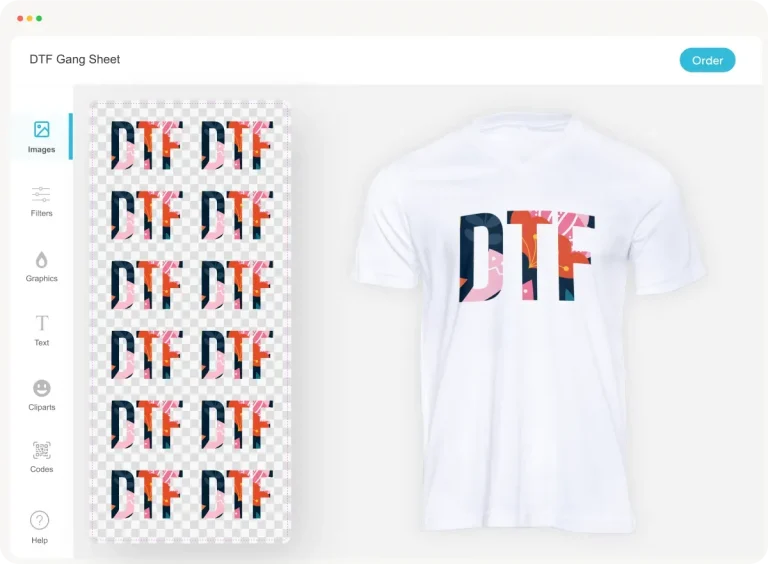

DTF gangsheet builder streamlines production by intelligently arranging multiple designs on a single sheet. Its intelligent DTF nesting software analyzes dimensions, rotations, and margins to maximize material use and minimize waste. Behind the scenes, it enhances DTF printing efficiency by preserving color separations and reducing setup time. With features that support gangsheet optimization and seamless DTF workflow automation, shops can move from planning to production faster. This descriptive tool is designed for the web audience, highlighting DTF gangsheet features that boost efficiency and scalable performance.

Another way to describe this technology is as a layout and batching solution for transfer film printing, designed to assemble multiple designs onto a single production sheet. Called by many names—layout optimizer, gang-sheet planner, or production hub—it coordinates art, substrates, and color data to streamline prepress. The result is smoother automation of the digital-to-fabric workflow, less material waste, and faster throughput across orders. In short, businesses seeking efficiency rely on a tool that merges design bundling with sheet-aware strategies to scale output.

DTF gangsheet builder: Key features that optimize production and reduce waste

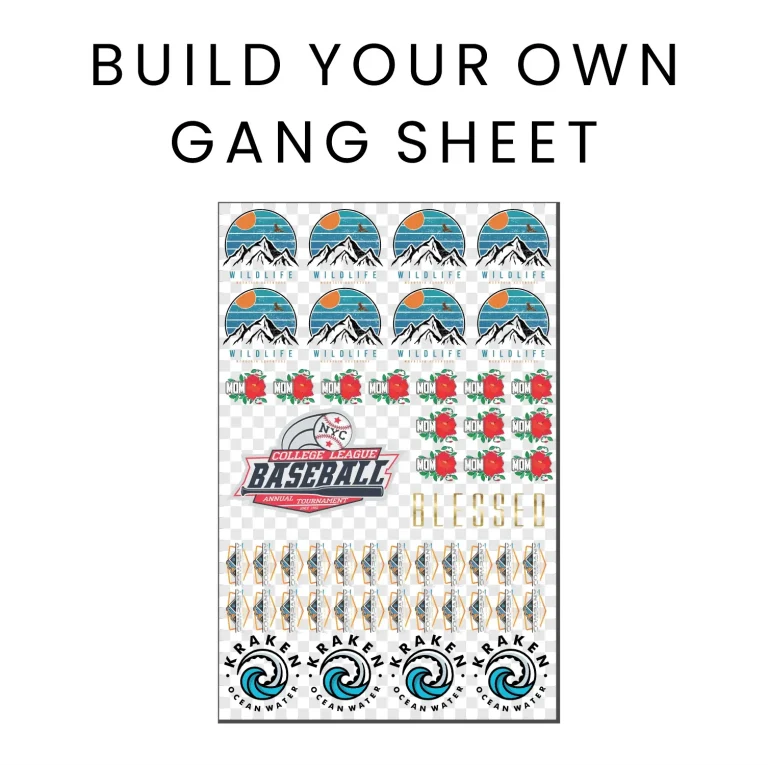

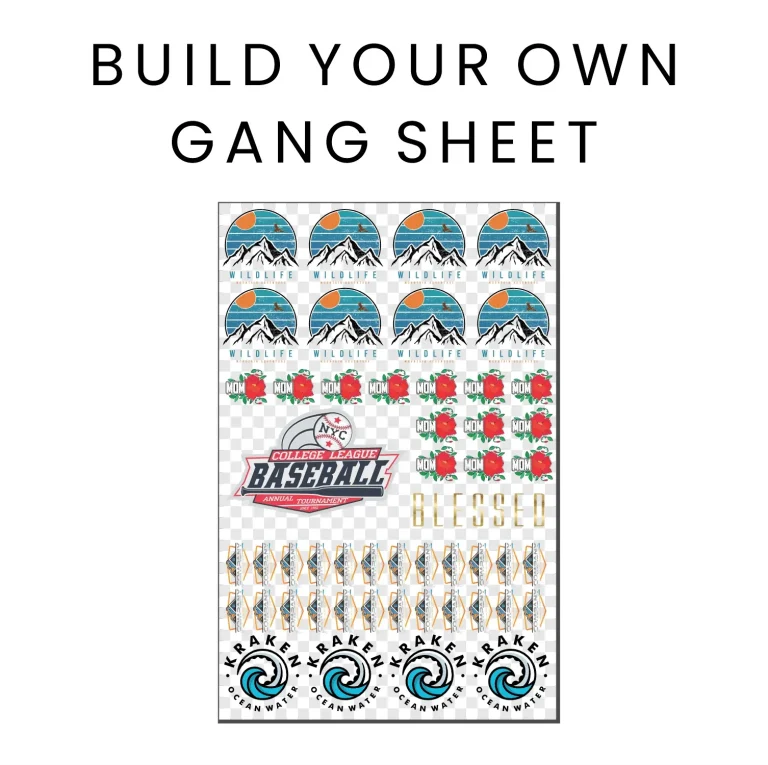

A DTF gangsheet builder harnesses intelligent auto layout and nesting efficiency to pack multiple designs onto a single sheet. By leveraging DTF nesting software, it analyzes dimensions, rotation options, and margins to maximize sheet usage, which directly boosts DTF printing efficiency and minimizes material waste. This core capability reduces manual rearrangement and accelerates throughput, letting operators focus on quality checks and finishing tasks.

Color management and separation compatibility are critical for vibrant, reliable prints. A high-quality DTF gangsheet builder preserves accurate color separations when designs share a sheet, minimizing color bleed and misregistration. The result is higher first-pass yield and fewer reprints, which translate to lower costs and faster order fulfillment.

Size and margin control, templates, and reusable designs empower consistent layouts across orders. Granular placement guarantees safe zones for all target garment sizes, while templates enable rapid reproduction of proven configurations for recurring clients. Multi-design optimization and multi-sheet planning further increase efficiency, balancing ink coverage and sheet capacity across several sheets to maximize output without sacrificing print quality.

Maximizing shop throughput through gangsheet optimization and workflow automation

Gangsheet optimization, including multi-design planning and multi-sheet handling, is a keystone of scalable production. A capable system distributes layouts to balance ink usage, color constraints, and substrate limits while integrating with RIPs to transfer color profiles and print settings directly into the production queue. This seamless data flow is the essence of DTF workflow automation, reducing manual entry and minimizing human error.

Material and ink type support ensure layouts are tuned for different substrates—polyester, cotton blends, and specialty finishes—so ink usage stays efficient without compromising fidelity. Coupled with robust integration, reporting, and analytics, shops gain visibility into waste, throughput, and bottlenecks. The result is faster setup, improved throughput, and a scalable pathway to handle growing order volumes while maintaining consistent quality.

For shops experimenting with automation, pilots and pilots-informed adjustments are essential. A tool that offers detailed production reports, waste metrics, and performance dashboards helps teams quantify gains from gangsheet optimization and DTF workflow automation. With scalable plans and ongoing updates, the right DTF workflow solution evolves with your business, turning daily operations into a consistently efficient, automated production line.

Frequently Asked Questions

What are the top DTF gangsheet features of a DTF gangsheet builder that boost DTF printing efficiency?

DTF gangsheet builder’s top features enable efficient packing of multiple designs onto a single sheet. Auto layout and intelligent nesting minimize waste and reduce setup time, directly improving DTF printing efficiency. Strong color management, size/margin controls, and template reuse ensure accurate, repeatable results across orders. Together, these DTF gangsheet features streamline prepress and production, boosting throughput.

How does DTF nesting software within a DTF gangsheet builder enhance gangsheet optimization and DTF workflow automation?

DTF nesting software inside a DTF gangsheet builder automates how designs are arranged, balancing ink coverage and sheet capacity while respecting color separations. This supports gangsheet optimization by maximizing substrate use and reducing waste, while enabling smooth DTF workflow automation through RIP integration and automated data transfer. The result is faster setup, higher throughput, and consistent print quality across jobs.

| Key Point | Description |

|---|---|

| What is a DTF gangsheet builder | Software that automatically arranges multiple designs into one or more production sheets (gangsheets) for DTF printing, packing designs on a single sheet to maximize material use while respecting color separations, margins, and substrate limits. |

| Auto layout and nesting efficiency | Intelligent auto layout analyzes design dimensions, rotation options, and margins to nest designs on a sheet, reducing waste and enabling larger batches with less manual rearrangement. |

| Color management and separation compatibility | Ensures accurate color separations are preserved when designs are packed together, minimizing color bleed and misregistration for higher first-pass yield. |

| Size and margin control | Granular control over placement, margins, and safe zones to fit all target sizes without overlapping ink or clipping on edges. |

| Template and reusable designs | Save proven gangsheet layouts as templates to quickly reproduce configurations for recurring clients or product lines, speeding planning and production. |

| Multi-design optimization and multi-sheet planning | Handles multi-design and multi-sheet layouts, balancing ink coverage, color constraints, and sheet capacity across several sheets for high-volume throughput. |

| Material and ink type support | Recognizes substrate nuances and adapts layouts to minimize ink usage while preserving print fidelity; supports preferred inks and transfer films. |

| Integration with RIP and production workflow | Seamless data exchange with RIPs and production systems so color profiles, print settings, and ink estimates flow into the print queue. |

| File compatibility and ease of import | Supports common formats (PNG, JPEG, PSD, TIFF, SVG) and preserves layers/transparency to enable quick re-use of designs. |

| Job management and reporting | Provides visibility into job status, material usage, waste, and productivity with dashboards and reports for data-driven decisions. |

| Real-world benefits | Increased DTF printing efficiency, reduced waste, faster setup, more accurate color, improved workflow automation, and scalable solutions for shops of all sizes. |

| Choosing a DTF gangsheet builder | Assess bottlenecks (layout/setup), check integration with RIP/workflow, evaluate scalability and support, review reporting capabilities, and test with real jobs to validate improvements. |

| Impact across sizes and markets | Benefits extend from small studios to large shops: better nesting, lower per-unit costs, faster quotes, and reliable lead times through gangsheet optimization. |

Summary

The table above summarizes the key concepts of a DTF gangsheet builder and how its features translate into real-world shop benefits, emphasizing auto layout, color management, templates, and automated workflows to boost efficiency and material utilization.