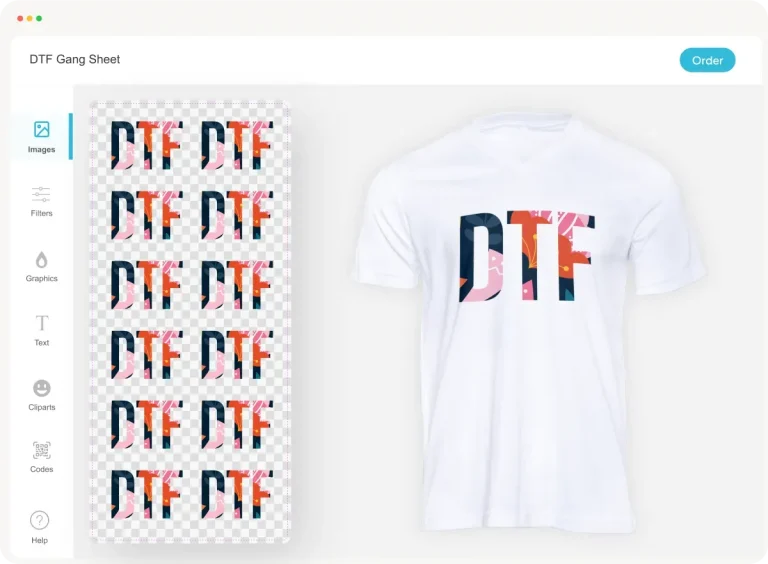

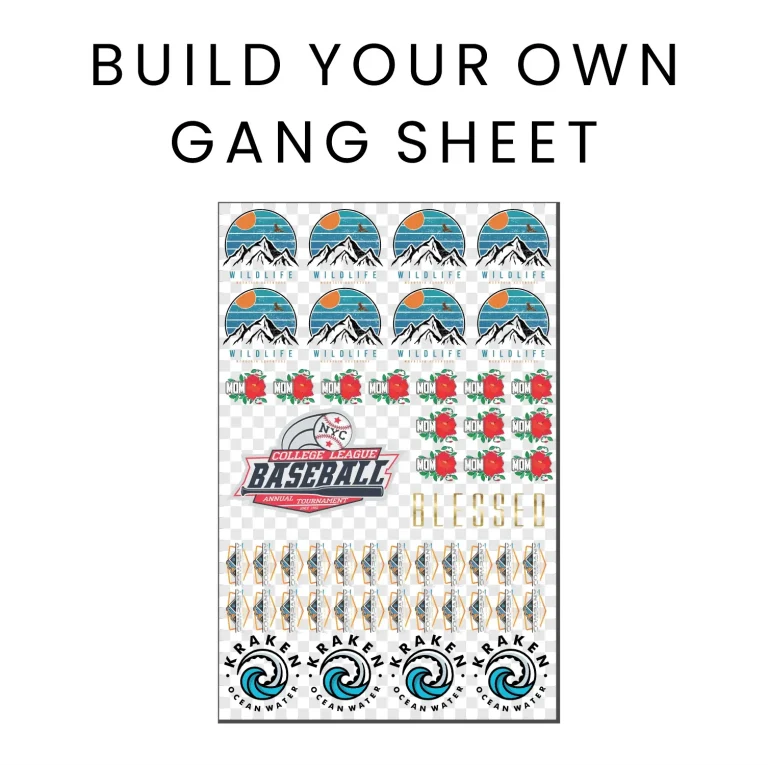

In the fast-paced world of custom apparel, efficiency isn’t just a goal—it’s a competitive necessity that drives repeat business. A DTF gangsheet builder helps teams maximize throughput by automating the layout of multiple designs on a single transfer sheet, boosting DTF printing productivity. By combining gangsheet optimization with DTF workflow automation, shops reduce setup times, minimize waste, and standardize color handling. The approach is illustrated by a case study DTF printing, where a mid-sized shop adopted the tool to elevate DTF production efficiency and reliability. The result is faster, more predictable prepress and consistent results across orders, giving shops a tangible edge.

Viewed through a different lens, this concept becomes a sheet-layout solution for transfer-print workflows that batches multiple designs into a single pass. Focusing on automated prepress, color consistency, and standardized asset handling, shops can scale output without compromising quality. Think of it as a design-batching engine that coordinates artwork metadata, print sequencing, and color profiles to speed production. As automation tools evolve, practical examples show how throughput, turnaround times, and consistency improve without adding staff.

Frequently Asked Questions

How can a DTF gangsheet builder improve DTF production efficiency and enable workflow automation?

A DTF gangsheet builder automates the layout of multiple designs on a single transfer sheet, accelerating prepress and enabling true DTF workflow automation. It optimizes margins, bleed, color separations, and placement in sync with your RIP and ICC profiles, delivering consistent color across orders and reducing misprints. This approach boosts DTF printing productivity by cutting manual layout time, minimizes setup changes, and scales with multiple SKUs for higher throughput. In a case study, shops saw prepress time drop about 32%, waste reduced ~22%, daily throughput up ~17%, and changeover time shrink about 25%, demonstrating tangible DTF production efficiency gains.

What steps should a shop take to implement a DTF gangsheet builder for gangsheet optimization, and what outcomes might be expected?

Start with standard sheet sizes and baseline print parameters, then build templates and catalog designs with metadata to guide automated layouts. Run parallel tests comparing builder-generated gang sheets with manual layouts, train operators on review processes, and establish go/no-go checks to ensure quality. In a practical case study, these steps yielded a 32% average reduction in prepress time, about 22% less material waste, a 17% increase in daily production throughput, and roughly 25% shorter changeovers, illustrating how proper templates, color workflows, and ongoing iteration enhance DTF production efficiency and gangsheet optimization.

| Aspect | Key Points |

|---|---|

| What is a DTF gangsheet builder? |

|

| Why this matters for productivity |

|

| Case study starting point |

|

| Implementation plan & early wins |

|

| Initial productivity gains |

|

| How it drives productivity |

|

| Outcomes: measured impact |

|

| Practical tips for implementation |

|

| Common challenges |

|

| Future-proofing with automation |

|