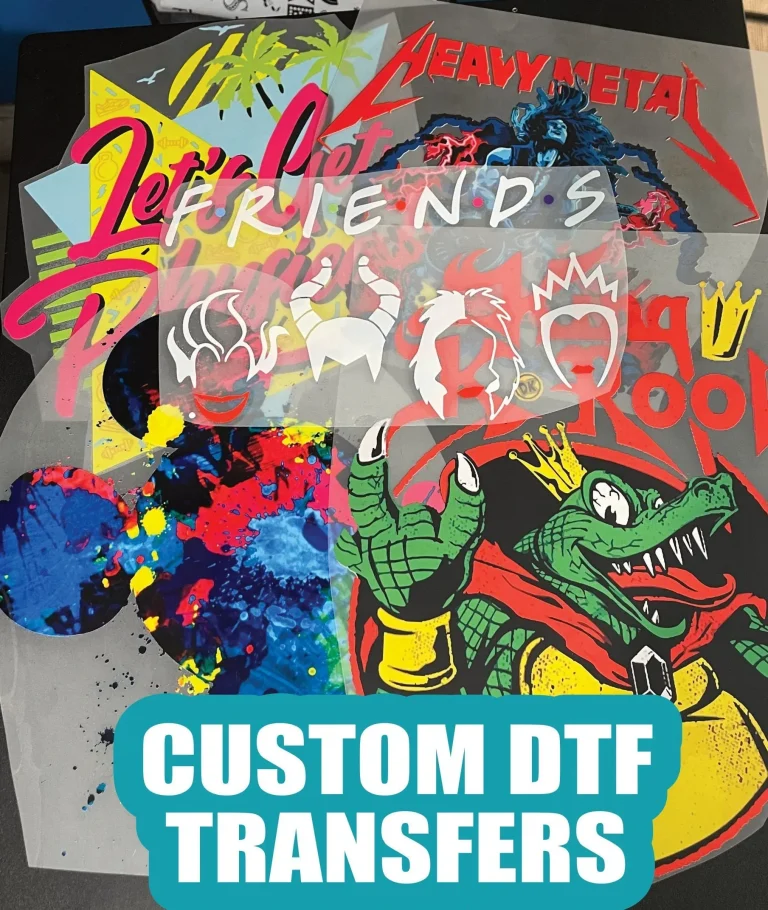

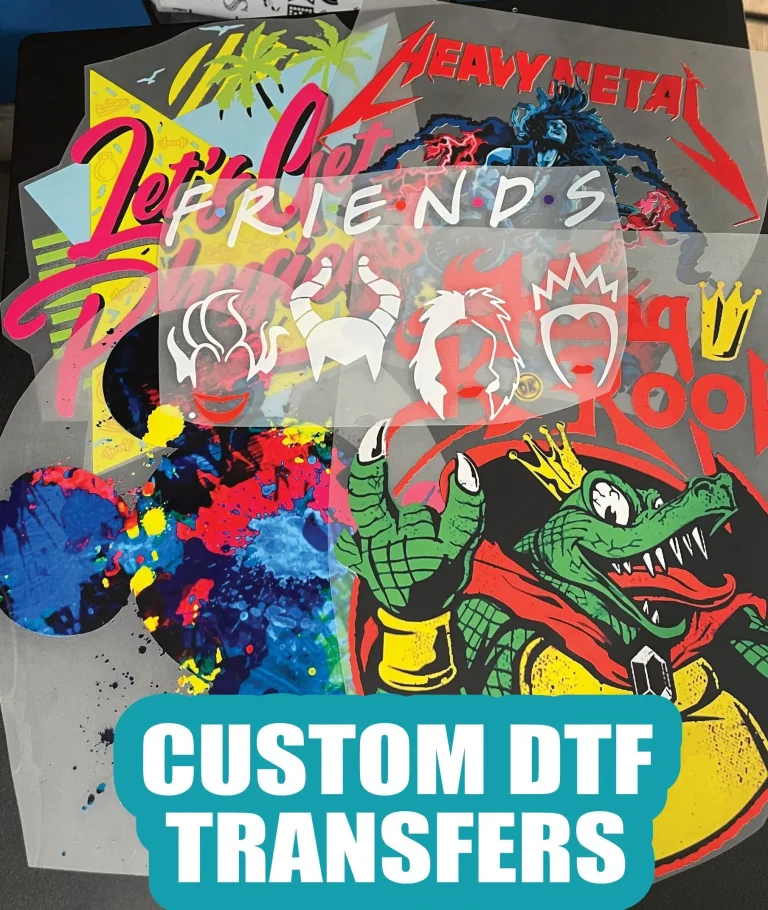

DTF transfers have transformed how custom apparel is made, delivering vibrant color, durable adhesion, and a forgiving workflow for hobbyists and small shops. For designers aiming crisp images on T-shirts, hoodies, tote bags, or fabrics with a soft hand, mastering DTF printing can streamline production and unlock new creative possibilities. This guide outlines a practical, step-by-step approach that covers design, printing, powder bonding, and the essential steps for successful application. By focusing on the fundamentals of the transfer workflow, you can achieve consistent results whether you are printing a single order or running a small business. To ensure durability and color fidelity across a range of fabrics, follow best practices during preparation, pressing, and finishing.

Viewed from another angle, this direct-to-film technique treats the design as a printed sheet that is bonded to fabric through heat and a specialized adhesive, delivering durable results on a wide range of textiles. LSI-friendly terminology like film-to-fabric decoration and transfer adhesion emphasizes the same concept while widening the semantic field around the process, from design to final garment. When you optimize the DTF transfer application workflow, you gain control over alignment, color fidelity, and wash durability across small runs and large batches. To maximize reliability, consider practical cues such as how the film is handled, the recommended DTF curing tips, and how the heat press tempo is matched to fabric type.

DTF Transfers: Practical Guide to DTF Printing, Film Setup, and Transfer Application

DTF transfers open new possibilities for custom apparel, delivering vivid color reproduction, flexible fabric compatibility, and a simple, forgiving workflow that suits hobbyists and small shops. Whether you’re printing on T-shirts, hoodies, tote bags, or fabrics with a soft hand and long wear, mastering DTF transfers can elevate your products while keeping production approachable.

To master the DTF workflow, you need to understand the full process from design to final transfer. The core steps include designing for the substrate, printing with DTF printing principles onto PET film, and applying an adhesive powder via a proper DTF film setup. When you combine accurate film setup with a consistent heat press, you achieve a reliable DTF transfer application with crisp edges, strong adhesion, and durable color under a range of fabrics.

Mastering Heat Press Techniques for DTF: From Pre-Press to Curing and Durability

Effective heat press techniques for DTF begin with a thorough pre-press to remove moisture and reduce wrinkles. Align the transfer with the garment using a jig or guides, place a silicone or Teflon barrier sheet over the design, and apply even, steady pressure at the recommended temperature for a careful, timer-based duration. This attention to pre-press, temperature, and pressure is essential to minimize ghosting and ensure consistent adhesion across the print.

After the main press, follow the appropriate peel method—hot, warm, or cold—based on the adhesive powder you used, and consider a brief post-press to lock the print into the fabric. For durability, incorporate DTF curing tips such as controlled powder curing, temperature calibration of the heat press, and testing on swatches before large runs. By integrating these heat press techniques for DTF with proper curing and post-care, you can extend wash durability and maintain color integrity across garments.

Frequently Asked Questions

What are the essential steps of DTF transfer application and heat press techniques for durable, vibrant results?

DTF transfer application begins after you print the design on PET film with a white base. For heat press techniques for DTF, pre-press the garment to remove moisture, set your press to about 160–170 C (320–340 F), and press with even pressure for 12–20 seconds. Apply an even layer of adhesive powder (DTF curing tips: use a powder shaker, melt and cure evenly, then brush off excess). Place the transfer on the garment with the design facing down, cover with a silicone or Teflon barrier sheet, and press again. Peel according to the adhesive guidelines (hot, warm, or cold) to reveal the finished image. A brief post-press can improve durability. Ensure proper DTF film setup by keeping the film flat and aligned to avoid skew and edge lift.

How should I set up DTF film and apply curing tips to ensure consistent results across different fabrics?

DTF film setup starts with printing for DTF printing on PET film using the correct orientation; in most workflows you do not mirror the image in advance because the adhesive powder will transfer the image correctly. After printing, cure the adhesive powder evenly (DTF curing tips) with a shaker to apply a uniform coat, then melt and cure as required. Pre-press the garment to remove moisture, align the transfer using marks or a jig, and cover with a barrier sheet. Heat press at 160–170 C (320–340 F) for 12–20 seconds with steady pressure, then peel according to the adhesive spec (hot, warm, or cold). Test on fabric swatches and adjust temperature and time for each fabric type to maintain consistency. Regularly calibrate your heat press and keep the DTF film setup clean to prevent texture or adhesion issues across fabrics.

| Section | Key Points | Practical Tips |

|---|---|---|

| What are DTF transfers and why choose them | DTF stands for direct-to-film printing. Design is printed on PET film with a water-resistant adhesive and transferred to fabric with a heat press. Benefits include vibrant color, good fabric stretch, and compatibility with many fabrics. Uses a powder adhesive for durable results and a relatively simple workflow, appealing to hobbyists and small businesses. | Use a printer compatible with DTF workflows, pair with appropriate film and adhesive, and test on sample fabrics. Ideal for small orders, multicolor designs, or on-demand printing. Follow the step-by-step process for best results. |

| What you need to get started | DTF film and adhesive powder; printer or DTF workflow setup; heat press; silicone or Teflon sheet; pre-press setup (garment rack or flat surface); optional powder shaker, curing/dryer, and a cutting tool. | Keep a clean workspace; calibrate your printer; choose substrates compatible with DTF; have barrier sheets and storage for powders ready. |

| Step 1: Prepare the design and print | Create a high-quality design sized for the substrate; ensure vibrant colors and solid edges. Print onto PET film with a white base and color channels; align artwork for the garment; generally do not mirror the image. | Use color management, print tests, and alignment marks. Verify orientation and sharpness before proceeding. |

| Step 2: Apply and cure the adhesive powder | Apply a fine, even layer of adhesive powder to the printed side. Powder melts and bonds during heat. Use a powder shaker; cure per equipment guidelines; gently brush off excess powder. | Ensure an even coat; avoid clumps; follow cure times; remove excess powder after curing. |

| Step 3: Pre press the garment | Pre-press to remove moisture and wrinkles, flatten fabric, and reduce ghosting. Typical 3–5 seconds at moderate temperature; use a barrier for delicate fabrics if needed. | Use a garment rack or flat surface; verify fabric is flat; adjust time for fabric type. |

| Step 4: Position the transfer and begin the heat press | Place the transfer on the garment with design facing down. Use alignment marks or a jig. Cover with a silicone or teflon sheet. Press at 160–170 C (320–340 F) for 12–20 seconds with even pressure. Do not move the transfer during pressing. | Use alignment aids; test on similar fabrics; monitor temperature and time; avoid movement during pressing. |

| Step 5: Peel the film at the right moment | Peel after pressing according to adhesive guidelines. Some require a hot peel while still warm; others a warm or cold peel after cooling. Proper peel prevents edge lifting; re-press briefly if needed for durability on dense fabrics. | Follow adhesive specifications; peel consistently; re-press if edges lift. |

| Step 6: Optional post press for durability | Optional short post-press to lock the print into the fabric. 2–3 seconds at the same temperature with a barrier sheet helps adhesion and wash durability. Avoid gloss or distortion; test on samples first. | Include post-press as needed; test on samples to set expectations. |

| Common mistakes to avoid | Inadequate pre-press, uneven powder coating, incorrect temperature or time, skewed alignment, lack of protective barrier. | Always pre-press to flatten fabric; apply powder evenly; follow manufacturer ranges; use alignment aids; protect print with barrier sheets. |

| Pro tips for better results | Use quality DTF supplies; keep printer tuned; manage powder environment; calibrate heat press; test on swatches; maintain a production/log; test various film/adhesive brands. | Document settings; run regular print quality checks; maintain equipment; perform trials on swatches before larger runs. |

| Troubleshooting and care after applying | If peeling, cracking, or color loss occurs, review pre-press, post-press, and powder steps. Wash garment per care guidelines; turn inside out; use cold or warm water; avoid high-heat drying. | Reassess steps, adjust heat and time, and ensure proper washing care. |

| DTF transfers vs other methods | DTF transfers offer a flexible alternative to screen printing or iron-on methods, especially for small runs, complex multicolor designs, and on-demand printing. They provide vibrant colors and durable results; evaluate setup costs, run length, fabric compatibility, and design change flexibility. | Compare with screen printing and iron-on methods; plan for costs, orders, and fabric types; ensure prep quality. |

| Data-driven optimization and ongoing improvements | Track results to identify patterns that improve outcomes. Maintain a simple log (fabric type, pre-press time, transfer temp, press duration, peel type, color shifts, edge lifting). Test brands of film and powder to determine best combinations; use data to improve quality and efficiency. | Keep a running data log; run controlled tests; adjust process based on results. |

| Conclusion | A concise summary of the base content highlights the practical DTF transfer workflow and its outcomes. | Focus on design prep, adhesive powder, pre-press, calibrated heat pressing, and proper peeling for consistent results. |