DTF gangsheet builder reshapes how apparel printers plan transfers by packing multiple designs onto a single sheet. This approach maximizes substrate usage, reduces waste, and speeds up production while maintaining color accuracy and consistency across orders through smart DTF printing layout practices, clear standards, and repeatable checklists. In this guide, you will learn how to design layouts, how to manage bleed in DTF printing, and how to control color with best-practices and a reliable workflow for creating DTF gang sheets, including practical templates, sample sheets, and validation steps. We will cover margins, gaps, safe zones, and explain how these align with gangsheet layout best practices to ensure consistent trimming and predictable outcomes, plus tips for on-press checks that save time. Whether you are a small shop, a POD creator, or just starting with DTF, adopting a structured gang sheet strategy supports DTF color management and delivers reliable, high-quality results across fabrics and substrates.

From another angle, think of this topic as the work of a transfer sheet planner or multi-design sheet designer, focused on efficient composition and repeatable results. Other terms that capture the idea include gang sheet designer workflow, sheet layout optimization for transfers, and color-stable batch processing. By using LSIs, search engines and readers see connections to topics like DTF transfer layout, bleed guidelines, and color management in fabric printing, which broadens the relevance of the guide. This framing helps ensure the content remains practical, actionable, and easy to navigate for creators aiming to streamline production while preserving print fidelity.

DTF gangsheet builder: Layout mastery, bleed optimization, and color management for scalable production

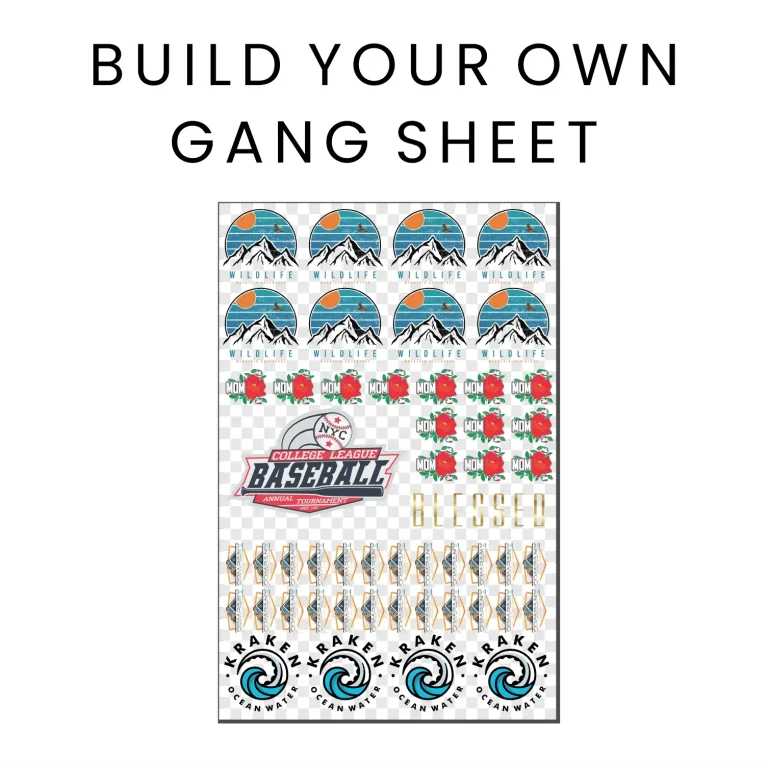

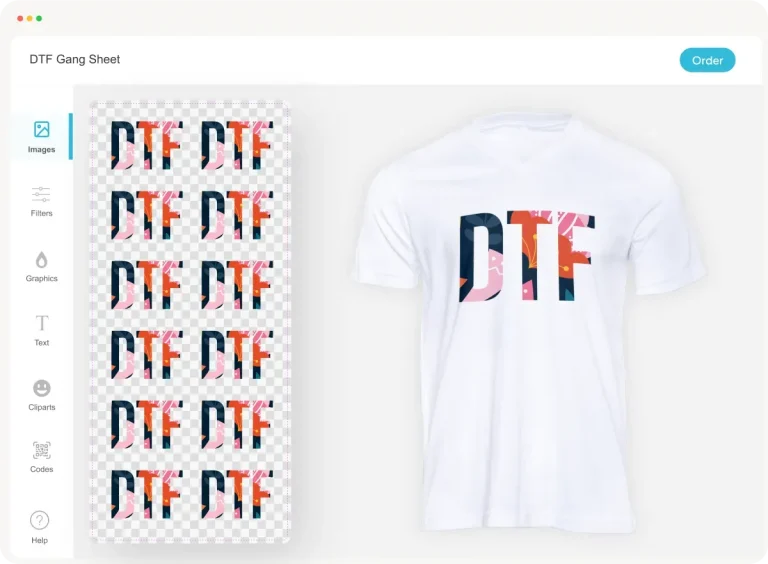

The DTF gangsheet builder is a workflow approach that groups multiple designs onto a single printable sheet, optimizing substrate use and speeding up production. This aligns with core DTF printing layout concepts, ensuring that each design fits cleanly within a grid and preserves legibility across varied product sizes. By embracing creating DTF gang sheets as a standard practice, shops can achieve consistent sizing, spacing, and alignment that translate into repeatable results and fewer reprints.

Effective gangsheet layouts rely on following gangsheet layout best practices: a clean grid, uniform margins, and deliberate bleed zones. When you plan with these principles in mind, you minimize mis-registration and streamline post-processing. The builder approach also helps standardize how you handle color blocks, host design elements, and spacing so that every sheet can be produced with the same level of precision.

DTF printing layout essentials: Bleed, color management, and creating DTF gang sheets

Bleed considerations in DTF printing are crucial to avoid white edges after trimming. Incorporating a consistent bleed—typically around 0.125 inches (3 mm)—along with a defined safe zone ensures that color extends to the edge and important details stay within the final trim. This mirrors the practical needs of creating DTF gang sheets, where accurate bleed and trim guides prevent seams or gaps once transfers are applied.

DTF color management is the backbone of reliable multi-design prints. Working in a consistent color space (CMYK for print), calibrating displays, and using proofing steps (digital soft proofs and physical tests) help predict color shifts before you commit to a full gangsheet print. By integrating DTF color management into your workflow and documenting export settings, you can reproduce exact hues across orders and clients, reinforcing the reliability of your gangsheet creation process.

(Optional) Implementation tips and ongoing optimization for scalable DTF gang sheets

To further optimize, establish an SOP for gangsheet creation that covers planning, bleed management, and color verification. Save master templates with grid layouts and color references so team members can reproduce results quickly. Regularly review proofs against physical tests to catch drift early and keep your DTF gangsheet builder producing consistent outcomes.

Continuous improvement comes from feedback loops: track each run’s results, adjust spacing or bleed as needed, and maintain a library of approved designs. By applying the principles of designing DTF gang sheets with attention to grid integrity, bleed accuracy, and color fidelity, you’ll sustain quality and efficiency as production scales.

Frequently Asked Questions

What is the DTF gangsheet builder and how does it improve DTF printing layout and color management?

The DTF gangsheet builder is a workflow that arranges multiple artwork transfers on a single sheet to maximize substrate usage and ensure consistent size and color across orders. In DTF printing layout terms, it uses a precise grid, margins, gaps, and bleed planning so designs print and trim cleanly. It also supports DTF color management by coordinating color spaces, soft proofs, and test prints to preserve color fidelity when creating DTF gang sheets.

What are gangsheet layout best practices for creating DTF gang sheets?

Start with a clean grid aligned to your printer’s capabilities, then set uniform margins and gaps. Include a bleed of about 0.125 inches (3 mm) to prevent white edges in bleed-in DTF printing. Use safe zones and trim guides, place designs within their cells, and perform soft-proofing (and a physical proof if possible) before exporting high-quality files (PNG or TIFF) for production. Maintain consistent DTF color management with CMYK workflows, color references, and a test print to ensure reliable results when creating DTF gang sheets.

| Topic | Key Points |

|---|---|

| DTF gangsheet concept and purpose | A gangsheet is a single printable sheet carrying multiple artwork transfers; enables grouping several designs on one sheet to save material and ensure consistent color and sizing across orders; aims to optimize space while keeping each design legible, aligned, and color-accurate. |

| Layout fundamentals | Use a clean grid sized to printer capabilities; create evenly spaced columns and rows; align designs to a baseline grid to ensure consistent margins and reduce mis-registration during transfer; supports faster batching. |

| Margins and gaps | Set safe margins around each design to prevent overlap; maintain uniform gaps to simplify trimming; spacing depends on cutter/trimmer; choose repeatable values for future gang sheets. |

| Bleed | Bleed is extra image area beyond final trim to extend color to edges; typical bleed for DTF small-to-mid designs is around 0.125 inches (3 mm); verify with printer specs; including bleed reduces visible seams. |

| Safe zones and trim guides | Establish a safe zone inside each design for critical elements; use trim guides to indicate final cut; helps keep details intact after transfer. |

| Color management | Work in CMYK color space; calibrate monitor; convert RGB to CMYK with soft-proofing; Pantone references for precise targets; print a small color test strip on same material before full gangsheet. |

| Proofing | Do digital soft proof and, if possible, a physical proof on same substrate; compare colors and grayscale; follow a workflow: convert, proof, adjust, reproof. |

| File setup and output | Canvas size matches sheet; set resolution to 300 DPI; keep vector elements scalable; manage layers: transparent overlays vs solid fills; export as high-quality PNG or TIFF with no compression; retain layered formats for edits; document export settings for reproducibility. |

| Practical steps for building a gang sheet | Plan sizes and quantities; create a master sheet with grid, margins, bleed, trim guides; place designs within cells respecting margins; add host elements outside safe zones; check for overlaps; soft-proof; export and test; iterate based on test print feedback. |

| Common pitfalls | Rushing layouts leads to misalignment; neglecting bleed causes white edges after trim; color shifts due to calibration or substrate differences; include color proofing in workflow and maintain a color reference library. |

| Tips for varied products | T-shirt designs: plan chest logos, sleeve, back; use consistent spacing; bags/accessories: adapt grid for non-standard shapes; save and reuse master templates across runs. |

| Teamwork and consistency | Create a standard operating procedure (SOP) for gangsheet creation; use a mental checklist before each print; maintain a centralized library of approved designs and color references to ensure consistency. |

Summary

Conclusion: Mastering the DTF gangsheet builder is about thoughtful layout, precise bleed, and careful color management. When you align these elements, your prints become more efficient, production costs drop, and your customers enjoy reliable, high-quality results. By building repeatable gangsheet layouts, you can scale operations, meet tight deadlines, and deliver consistent performance across garments and products. Plan the sheet, account for bleed and safe zones, verify color accuracy through proofing, and export clean, high-resolution files. The DTF gangsheet builder becomes a powerful tool for flawless prints and a competitive edge in the marketplace.