DTF Printing has transformed how small and medium-sized apparel brands bring custom designs to life, delivering vibrant color, flexible layering, and a streamlined on-demand workflow that keeps inventory lean, reduces lead times, and empowers designers to experiment with complex graphics without sacrificing production efficiency or margins during peak seasons. A gangsheet builder stands at the heart of this efficiency, optimizing film use, reducing setup waste, and accelerating production speed by intelligently grouping multiple designs onto a single sheet, which minimizes printer idle time, ink changes, and heat-press cycles while preserving color fidelity for printers, designers, and shop floor teams. This approach minimizes misprints and ensures tighter control over color alignment, making the DTF transfer smoother and more predictable across batches, especially as you scale collections or introduce new colorways, because the gangsheet method reduces variation between individual prints and streamlines the pre-press process and reduces in-process proofs. In practice, the DTF printing workflow benefits from a well-configured gangsheet system that consolidates preparation tasks, standardizes margins and bleed, and reduces handling between designs, producing a more repeatable process that aligns colors, tightens tolerances, and lowers the risk of costly reprints during busy production windows, even during seasonal product drops. With the right setup, brands can achieve faster turnarounds, reduce material waste, and deliver consistent results that satisfy customers while scaling operations to meet growing demand, and this approach supports creative freedom without compromising efficiency, making it a practical cornerstone for modern on-demand apparel production.

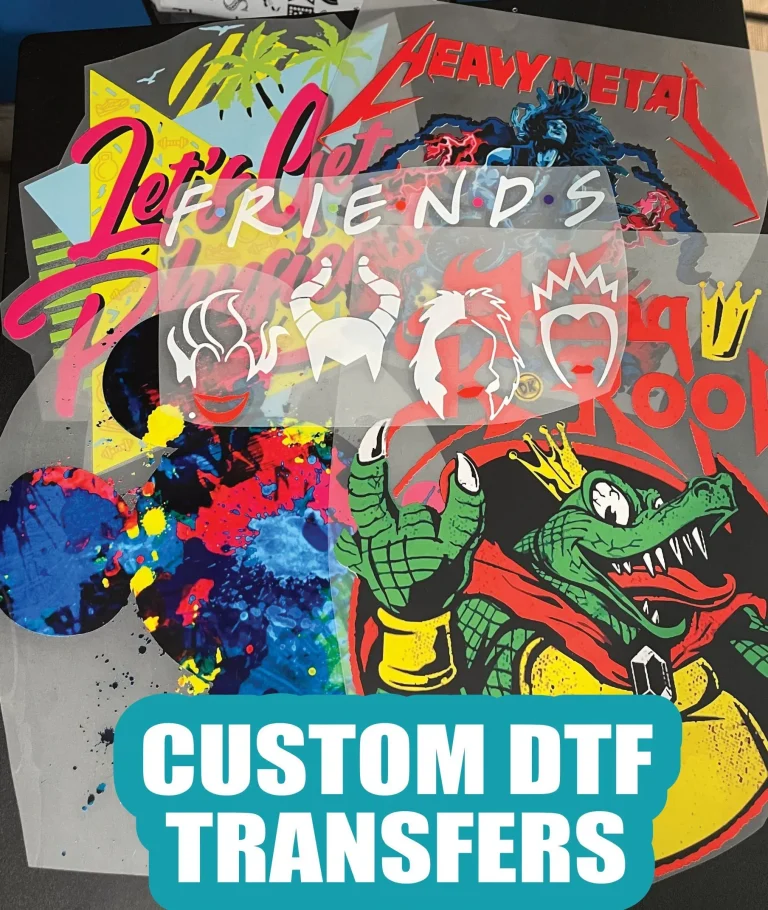

Viewed through the lens of direct-to-film technology, this approach reshapes how studios approach garment decoration, using film-based transfers to add imagery onto fabrics with a heat press. The technique, often called print-on-film or pigment-on-film decoration, offers broad substrate compatibility, bright color reproduction, and soft hand feel that appeal to on-demand manufacturing. By focusing on layout planning, color management, and process timing, teams can boost throughput, reduce waste, and deliver consistent results across collections.

DTF Printing Efficiency: Accelerating Production Speed with a Gangsheet Builder

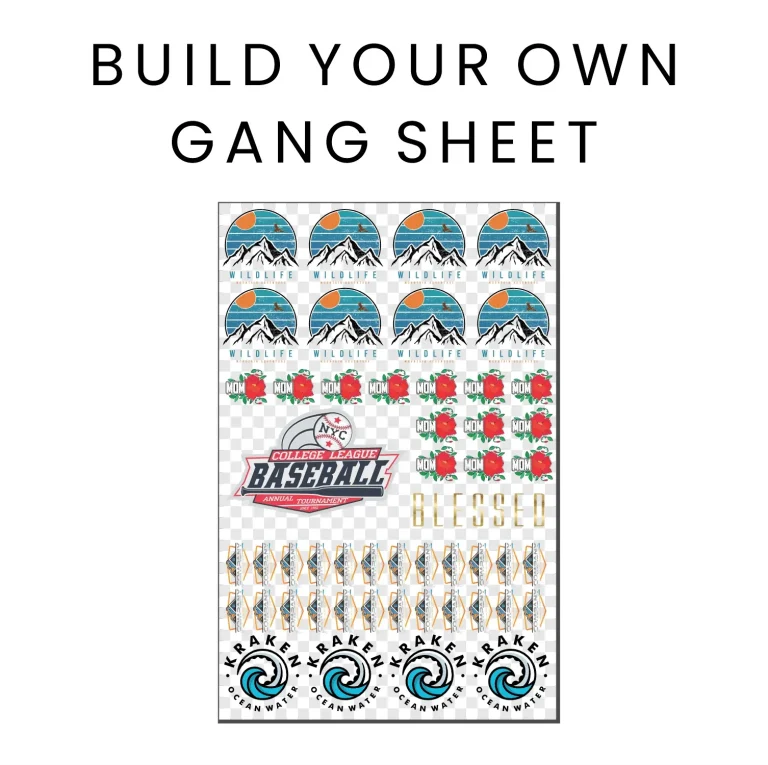

Using a gangsheet builder in DTF Printing consolidates multiple designs onto a single film, dramatically cutting film waste and reducing idle machine time. By printing a batch of designs on one sheet, you minimize the number of heat-press setups, ink changes, and re-registrations, allowing the production line to run longer between adjustments. This aligns with an optimized DTF printing workflow where each step—from design prep to transfer—focuses on speed without compromising fidelity, delivering higher production speed and more predictable turnaround.

To implement effectively, start with a catalog of repeat designs and create standardized margins, bleed, and color-management templates that the gangsheet builder can reuse. The tool automates design placement, enabling denser layouts while maintaining safe clearances for trimming. With calibrated color profiles, monitor calibration, and consistent heat-press parameters, you’ll experience fewer setup errors, less material waste, and faster batch processing, especially when handling multiple designs or colorways on a single gangsheet.

Optimizing the DTF Printing Workflow: From Artboard to Transfer with a Structured Gangsheet

Start with clean artboards and color separations, then use the gangsheet builder to arrange several designs on one sheet, optimizing spacing to minimize film waste while preserving edge-to-edge bleed control. This stage anchors your DTF printing workflow, ensuring consistent margins and placement across every design. By pre-planning during design prep and layout, you reduce last-minute edits and keep the printer’s run-time efficient, improving production speed without sacrificing quality, and you lower the risk of misalignment during the final DTF transfer.

Quality checks and troubleshooting live in the gangsheet process. Regularly verify alignment marks, test heat-press pressure, and confirm powder curing times to prevent adhesion issues on the final DTF transfer. A disciplined approach to layout management—paired with ongoing color management and post-print finishing checks—results in consistent transfers, fewer reprints, and a scalable DTF printing workflow that supports increasing order volume while maintaining high fidelity.

Frequently Asked Questions

How does a gangsheet builder impact production speed within a DTF Printing workflow?

By consolidating multiple designs on one film sheet, a gangsheet builder reduces the number of print passes and minimizes setup time between designs. This directly boosts production speed in a DTF Printing workflow by decreasing film changes, standardizing color separations, and maximizing film utilization, which speeds up batch completion without sacrificing DTF transfer fidelity.

What steps can I take to ensure consistent DTF transfer quality when implementing a gangsheet builder in my DTF Printing workflow?

To ensure consistent DTF transfer quality, maintain a library of repeat designs with fixed margins, calibrate color management and verify color separations, run test gangsheet layouts to validate fit and heat-press parameters, ensure proper curing and powder adhesion, and perform regular equipment maintenance. These practices reduce misalignment, color bleed, and adhesion issues in your DTF printing workflow and DTF transfers.

| Topic | Key Points | Notes / Benefits |

|---|---|---|

| DTF Printing Basics |

|

|

| DTF vs Other Methods |

|

|

| Gangsheet Builder: What It Is and Why It Matters |

|

|

| How Gangsheet Speeds Production |

|

|

| DTF Printing Workflow with a Gangsheet Builder |

|

|

| Practical Tips for Implementing a Gangsheet Approach |

|

|

| Common Pitfalls and Troubleshooting |

|

|

| Frequently Asked Questions |

|

Summary

DTF Printing offers a flexible, high-quality path for apparel brands to deliver custom designs on demand. A gangsheet builder is a practical tool for forward-thinking shops seeking to improve production speed while maintaining the integrity of each design. By consolidating multiple designs onto one sheet, you reduce film waste, shorten setup times, and achieve a more predictable DTF printing workflow. To scale operations, invest in a reliable gangsheet builder, train your team on efficient layout practices, and establish repeatable processes. With discipline and the right tools, you can accelerate production speed, deliver faster turnaround times, and keep customers satisfied with consistent, high-quality DTF transfers.