DTF transfers process has revolutionized garment decoration by delivering vibrant color reproduction, a remarkably soft hand feel, and strong adhesion across a wide range of fabrics, from cotton jerseys to poly blends, while maintaining comfort for wearability. In practice, designers begin with digital artwork, manage color separations and color spaces, and prepare artwork and films for the DTF printing stage, where a white underbase and CMYK layering are orchestrated for consistent results in the direct-to-film transfer workflow. The core steps—printing on a DTF film, applying an even layer of adhesive powder, and transferring with a calibrated heat press—significantly influence color fidelity, edge definition, substrate compatibility, and the durability of DTF transfers. Careful selection of DTF film quality, appropriate adhesive chemistry, and precise heat press settings for DTF tailored to cotton, polyester, or blends ensures reliable adhesion, minimal edge curl, and predictable wash performance. From design through curing and final inspection, a well-documented DTF workflow reduces waste, accelerates production, and supports scalability while helping teams optimize color management, film handling, and end-user care instructions.

Viewed through an LSI-informed lens, this technique fits a digital-to-film workflow that converts artwork into a printable film and primes it for garment decoration. From a broader perspective, the method is a film-based transfer approach that emphasizes color management, substrate compatibility, and reliable adhesion rather than direct fabric printing. In practical terms, teams think in stages: design input, film preparation, adhesive powder application, and a controlled heat application to seal the image onto textiles. This approach supports scalable production, robust durability, and versatility across fabrics, colors, and designs, while letting operators optimize film quality and press settings for consistent results.

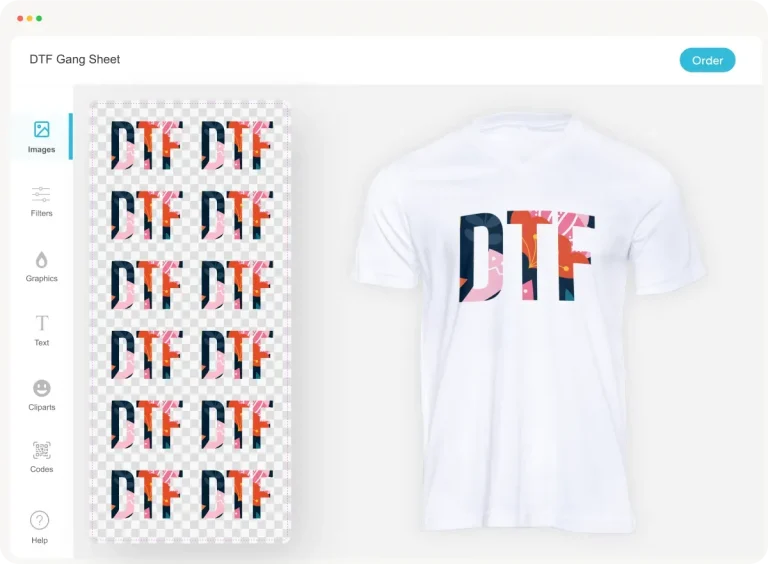

DTF transfers process: From Design to Delivery

The DTF transfers process begins with design and color management, laying the groundwork for a smooth DTF printing journey. Designers align artwork with garment types, set color budgets for CMYK workflows, and plan print areas, bleeds, and margins. They also account for the white underbase that many DTF systems require, ensuring the final result reads correctly on different fabric colors. Clear communication with production about substrate types—cotton, polyester, blends, or stretch fabrics—helps prevent surprises later in the process and keeps the momentum intact for direct-to-film transfer.

DTF printing involves moving the artwork onto a transfer film using a specialized printer capable of white ink and CMYK, followed by an adhesive powder that bonds the print to fabric during heat application. Film quality considerations are critical: look for uniform thickness, low curl, and stable surface to preserve color vibrancy and edge detail on the DTF film. After printing, adhesive powder is applied and the film is cured so the ink remains fixed, setting up predictable results when the film is later heated for transfer. The transfer phase itself hinges on heat press settings for DTF—temperature, time, and pressure must be tuned to the chosen film and garment.

Optimizing the DTF printing workflow for durable results

Choosing the right equipment is central to a reliable DTF printing workflow. A robust DTF printer with white ink capability, dependable RIP software, and quality DTF film pair with consistent adhesive powders to produce repeatable results. Evaluate printer reliability, ink stability, film quality, and platen sizes for heat presses to match garment dimensions. This stage also includes planning for different substrates—cotton, blends, or synthetics—so that the direct-to-film transfer behaves predictably across fabrics and keeps color fidelity high.

Quality checks and durability considerations are essential to ensure long life. From film and powder quality to proper curing and adhesion, every variable affects the durability of DTF transfers. Implement routine checks such as testing on representative fabrics, performing wash and wear simulations, and documenting heat-press times and temperatures. With consistent testing and careful attention to film quality and ink interaction, you can maximize the durability of DTF transfers and deliver reliable performance across multiple laundering cycles.

Frequently Asked Questions

What are the essential steps in the DTF transfers process, including DTF printing and DTF film preparation?

The DTF transfers process starts with design and color management, then printing on a DTF film using a direct-to-film workflow (white underbase followed by CMYK). After printing, adhesive powder is applied and the film is cured. The transfer is completed with a heat press using film-specific settings to achieve even adhesion; factors like film quality and proper curing impact the durability of DTF transfers. Testing on representative garments helps dial in the optimal heat press temperature, time, and pressure for consistent color and long-lasting results.

How do heat press settings for DTF influence the durability of transfers on different fabrics?

Heat press settings for DTF—temperature, time, and pressure—directly affect durability across fabrics. Typical ranges are 160–170°C (320–338°F) for 10–20 seconds with moderate to firm pressure, but you should follow your film and adhesive manufacturer guidelines. Use a warm or room-temperature peel as recommended and perform fabric-specific tests to ensure edge adhesion and wash-fastness. Consistent adhesive powder application and proper curing also influence the durability of DTF transfers.

| Stage | Key Points | Notes |

|---|---|---|

| Design & Preparation | Color management, color space, CMYK workflows, separations, bleed/margins, placement; account for white underbase and substrate types (cotton, polyester, blends, etc.) | Set foundation before printing; coordinate with production for fabrics and placements. |

| DTF Printing (Film) | Printing on PET transfer film; white ink first or as needed; color layering; film quality affects vibrancy and durability | Aim for consistent white underbase and reliable color layering; monitor film quality. |

| Adhesive Powder | Fine, heat-activated adhesive powder applied to film; bond between film and fabric; uniform coverage is essential | Powder quality and uniformity influence transfer adhesion and durability. |

| Curing & Drying | Dry and cure printed film so powder adheres properly and ink is fixed; reduces smudging | Crucial for predictable transfers and long-term performance. |

| Equipment | DTF printer, RIP software, film, adhesive powders; heat press compatibility; platen sizes; consumables | Reliability and maintenance impact consistency and downtime. |

| Transfer Phase (Heat Press) | Temperature 160–170°C; Time 10–20 seconds; Pressure: moderate to firm; Peel method: warm or room temperature | Follow manufacturer guidelines; run test sheets to dial in settings for each film/fabric combo. |

| Quality Checks & Durability | Substrate compatibility; ink/adhesive interaction; care/wash guidance; film and powder consistency | Inspect prints, test wash/durability, and ensure consistent results across lots. |

| Troubleshooting | Color mismatch, ghosting, peeling after washing, uneven compression | Revisit color management, curing, adhesion, and platen quality; use test prints. |

| Cost & Workflow | Bulk film/powder purchases, printer maintenance, efficient curing, batch processing, pre-warming garments | Optimize for throughput and consistency; high-quality equipment reduces downtime. |

| Comparison with Other Methods | Color/detail, fabric compatibility, production speed, durability differences vs DTG and HTV | DTF often excels on darker fabrics and blends; consider DTG/HTV trade-offs for specific use cases. |

Summary

The HTML table above outlines the key stages and considerations in the DTF transfers process, covering design prep, film printing, adhesive application, curing, heat-press transfer, quality checks, troubleshooting, cost/workflow, and method comparisons to other transfer options.