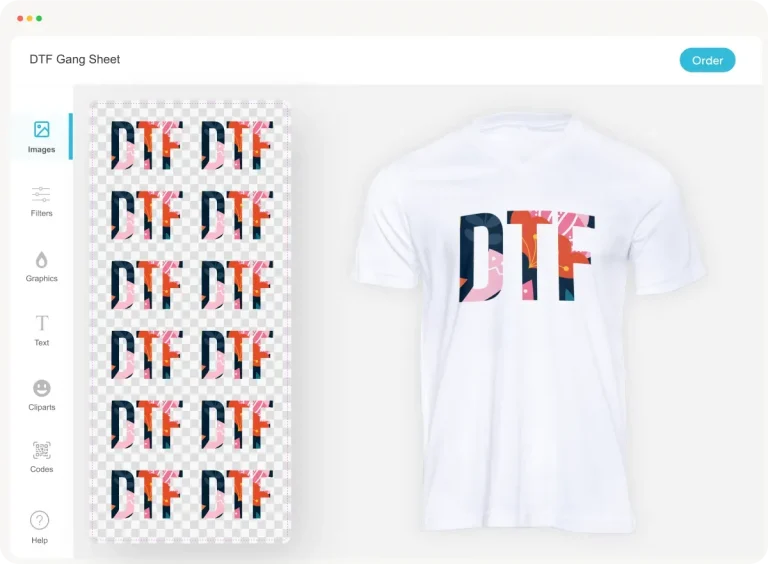

DTF gangsheet builder is transforming how shops optimize ink, time, and fabric usage on every run, turning complex batch layouts into streamlined prepress confidence and predictable, repeatable results that scale from small orders to high-volume productions. As you refine the DTF printing workflow, this tool helps you arrange multiple transfers on a single sheet with precise spacing and color consistency across different fabrics, colors, and printing beds. If you’re wondering how to create DTF gang sheets efficiently, the builder guides placement, improves waste control, and reduces the number of sheets required for faster proofs and smoother approvals. Design teams can leverage gang sheet design tips and reusable templates to speed up repeats, while operators benefit from predictable margins, alignment, and smoother color transitions. In practice, this technology supports DTF transfer optimization by predicting how inks will perform on different garments, ultimately delivering consistent results from one sheet to the next.

Beyond the specific tool, this approach functions as a sheet-packing and layout optimization system for Direct-to-Film workflows. Think of it as a prepress automation solution that coordinates multiple designs into cohesive gang sheets, reducing steps in production planning and aligning color management across garments. From a designer’s perspective, the focus shifts to efficient composition, high-contrast proofs, and scalable templates that transfer well to different print beds. For operations, the goal is predictable throughput, minimized waste, and smoother integration with RIP software, raising overall transfer quality and consistency.

DTF Printing Workflow Essentials: Maximizing Output with a DTF Gang Sheet Builder

In the DTF printing workflow, the ability to plan multiple designs on a single sheet is a major efficiency driver. A DTF gang sheet builder helps you arrange assets strategically to maximize fabric usage while keeping color accuracy and alignment intact. By visualizing the entire gang sheet before printing, shops can reduce waste, shorten setup times, and enable more predictable production for both small shops and larger operations.

Key benefits include waste reduction, enhanced consistency across runs, and streamlined prepress. With features like drag-and-drop layout, auto-fitting, and color management, you can rapidly test layouts, preview how designs will look on different fabrics, and export print-ready files that align with your RIP. This approach embodies the core ideas of the DTF printing workflow while safeguarding ink and materials.

To get started with how to create DTF gang sheets, select a sheet size that matches common garments, set appropriate bleeds, import high-resolution artwork, and begin packing designs in logical color groups. This preparatory step ensures efficient use of space and reduces the need for additional sheets during production. By pre-planning placements, you also simplify color separation and downstream steps like transfer finishing.

Gang Sheet Design Tips and Transfer Optimization

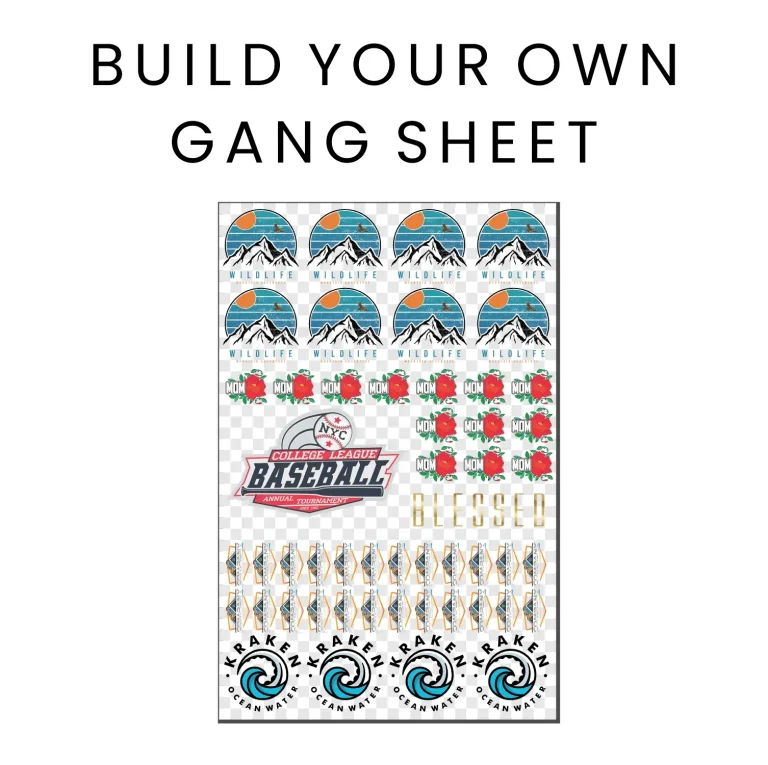

Gang sheet design tips begin with layout discipline: cluster designs by color families, maintain consistent margins, and leave adequate gutters to prevent ink bleed. These practices help maintain legibility and print fidelity, particularly when dealing with small logos or fine text on a range of garment colors.

For DTF transfer optimization, run small test transfers on representative fabrics before committing to full runs. Use color-managed profiles, verify ink density, adhesive behavior, and alignment marks, and adjust the color separations to compensate for fabric variability. Regularly validating the workflow across different garment types will improve predictability and reduce waste over time.

Frequently Asked Questions

What is a DTF gangsheet builder and how can it improve your DTF printing workflow?

A DTF gangsheet builder is specialized software that lets you plan the placement of multiple designs on a single gang sheet, optimizing material use and keeping colors accurate. It supports drag-and-drop layout, auto-fitting, tiling, color management, and previews, so you can create efficient gang sheets before printing. By organizing designs ahead of time, you reduce waste, shorten setup times, and improve repeatable color accuracy across batches in your DTF printing workflow.

What are essential gang sheet design tips to maximize efficiency with a DTF gangsheet builder for better DTF transfer optimization?

Follow these gang sheet design tips: 1) group designs by color families to minimize ink changes and improve color consistency; 2) maintain consistent margins and bleeds to ensure reliable transfer placement; 3) use templates and presets for common garment sizes to speed up production; 4) leverage auto-fitting and tiling to pack designs efficiently; 5) proof colors with soft previews and real-world tests on representative fabrics; 6) export print-ready files with embedded color profiles for your RIP. These practices support DTF transfer optimization and help you achieve reliable results across garments.

| Aspect | Key Points |

|---|---|

| Definition | A DTF gangsheet builder is software or a workflow component that lets you plan the placement of multiple designs on one gang sheet to minimize waste, ensure color consistency, and align transfers. |

| Why it matters | Delivers cost savings by packing designs, improves consistency with spacing and alignment rules, streamlines prepress workflows, and aids color management through previews and proofing. |

| Best features | Drag-and-drop layout; multiple sheet sizes and bleeds; auto-fitting and tiling; color management and proofing; export options; templates/presets; integration with design tools; reports and waste metrics. |

| How to use (step-by-step) | Define sheet size/margins, import designs, plan layout, rotate/mirror as needed, verify spacing, preview/proof, and export print-ready files. |

| Best practices | Plan color separation, maintain consistent margins, use high-contrast proofs, account for garment variability, build templates for top designs, and validate transfer settings. |

| Common challenges | Bleed/misregistration from tight layouts, color creep, and inconsistent garment placement; solutions include wider margins, color-managed profiles, and standardized templates. |

| Advanced tips | Automate repetitive tasks, create seasonal templates, integrate with RIP software, support variable data, and track waste/efficiency to refine workflows. |

Summary

Conclusion: A DTF gangsheet builder is a strategic tool that helps maximize efficiency, reduce waste, and deliver consistent, high-quality transfers. By understanding gang sheets, selecting the right features, and following best practices for design and production, you can streamline your DTF printing workflow, improve color accuracy, and scale your business with confidence. Whether you print a few designs or manage high-volume orders, investing in a robust DTF gangsheet builder pays off in faster turnarounds, lower costs, and happier customers. As the industry evolves, a thoughtful approach to gang sheets remains essential for reliable, repeatable results across all garment types.