DTF gangsheet builder opens a new era for growing apparel brands by turning multiple designs into efficient, single-press sheets that maximize output and minimize waste, to deliver faster turnarounds, more consistent colors, and lower material costs for brands expanding into new markets. In the crowded world of apparel, this technology optimizes sheet usage, speeds up setup, and supports the t-shirt printing workflow, all while reducing material waste and downtime, even in high-volume seasons. By automating layout and color management, this system aligns design, print, and production with real demand, helping brands scale without sacrificing quality, while preserving brand integrity across multiple SKUs. For brands pursuing growth with DTF, it translates creative ideas into repeatable production, predictable timelines, and healthier margins, across new channels, retailers, and direct-to-consumer platforms. This overview illustrates how DTF printing for t-shirts, gangsheet optimization, t-shirt printing workflow, print-on-demand DTF, and brand growth with DTF come together in a scalable, quality-first operation, accompanied by practical training, clear SOPs, and measurable dashboards that track utilization, waste, and on-time delivery.

Think of it as a sheet-optimization engine and a production-planning assistant that turns art assets into printer-ready layouts with minimal manual touchpoints. The approach relies on template-driven layouts, standardized color workflows, and automation that stitches orders to output files, ensuring predictable throughput and consistent results. In practical terms, the system reduces setup time, increases material efficiency, and lowers the cost per unit by optimizing ink use and alignments across multiple designs. For operators, this translates into repeatable processes, better scheduling, and smoother integration with order management and fulfillment—hallmarks of a resilient, on-demand printing operation.

DTF gangsheet builder: Catalyzing Print-on-Demand DTF and Brand Growth

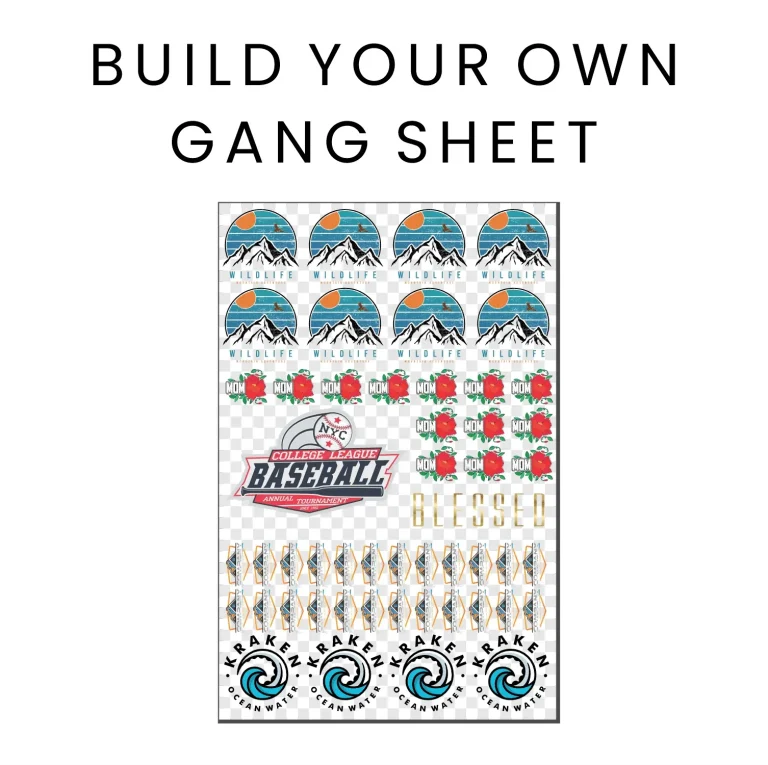

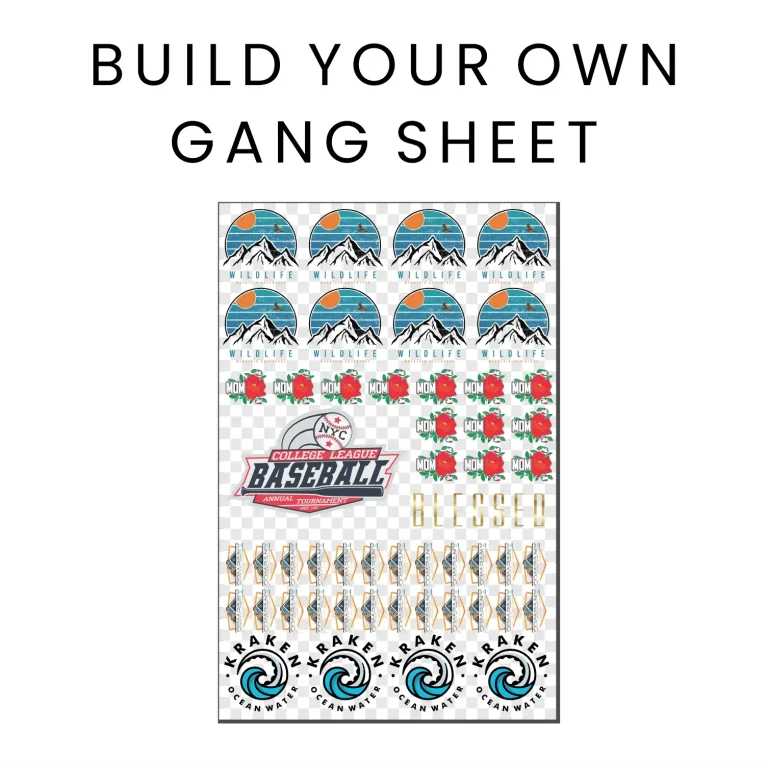

In DTF printing for t-shirts, a DTF gangsheet builder organizes multiple designs onto a single sheet, maximizing material usage, reducing waste, and speeding up the setup process. By bundling designs, brands can run more SKUs per batch without sacrificing transfer accuracy, enabling more consistent color and detail across orders.

This tool also aligns with a print-on-demand DTF model, making production more predictable and scalable. Through gangsheet optimization, color workflow standardization, and automated file prep, brands can grow with less friction, improving throughput and margins while maintaining fidelity to the artwork and the brand identity, ultimately supporting brand growth with DTF.

Enhancing the t-shirt printing workflow through gangsheet optimization for scalable production

From the perspective of the t-shirt printing workflow, adopting a DTF gangsheet builder reduces setup times, increases sheet utilization, and minimizes color drift between batches. The result is a more efficient production line that can handle higher volumes without compromising artwork integrity or consistency.

By enabling print-on-demand DTF with reliable lead times and consistent color output, brands can scale operations while protecting margins and quality. This approach supports brand growth with DTF by turning demand into a predictable, repeatable production process that aligns design, color management, and fulfillment.

Frequently Asked Questions

How does a DTF gangsheet builder improve gangsheet optimization and support brand growth with DTF in a t-shirt printing workflow?

A DTF gangsheet builder automates layout and color management for gangsheet optimization, consolidating multiple designs onto optimized sheets. This reduces material waste and setup time, standardizes color workflows, and speeds up the t-shirt printing workflow. For brands pursuing print-on-demand DTF and DTF printing for t-shirts, it improves throughput and consistency, supporting brand growth with DTF while keeping production predictable and quality high.

What steps should a brand take to implement a DTF gangsheet builder for scalable production and gangsheet optimization in a growing brand?

Implementing a DTF gangsheet builder involves a practical, phased approach: – Audit and baseline: catalog current orders, design complexity, and sheet sizes to establish metrics for gangsheet optimization. – Develop design templates: create templates for common artwork types to ensure consistent color separations and alignment. – Build intelligent gang sheets: the builder arranges multiple designs onto sheets with optimal margins, prioritizing ink colors, sizes, and print areas. – Standardize color management: implement swatch libraries and ICC profiles to reduce color drift across runs. – Integrate and automate: connect the gangsheet builder with order management so new orders flow automatically. – Train and SOPs: train staff on usage and standard operating procedures for prep, proofing, and daily QA. – Pilot and scale: test with a representative subset, then rollout across product lines. This aligns with t-shirt printing workflow, supports print-on-demand DTF, and drives brand growth with DTF by increasing throughput, reducing waste, and delivering consistent color quality.

| Topic | Summary | Growth/Impact |

|---|---|---|

| Definition and Core Function | A DTF gangsheet builder is a software/workflow that automatically arranges multiple design transfers onto gang sheets for Direct-to-Film printing, optimizing sheet utilization, managing color separations, and outputting print-ready files for minimal adjustment. | Enables scalable production by packing more designs per sheet, reducing setup time and material waste. |

| Scaling Relevance | As order volumes rise, it addresses bottlenecks in setup time, color consistency, and sheet optimization. | Faster throughput, lower costs, and greater capacity to meet peak demand. |

| Key Capabilities | Automates layout, optimizes sheet usage, standardizes color management with templates and ICC profiles, and integrates with order management for seamless workflow. | Reduces errors, improves predictability, and supports repeatable quality across batches. |

| Case Study Highlights | Brand A’s implementation led to 2.5x throughput in six months, setup time from 4.5h to 1.5h, ~18% waste reduction, improved color consistency, and higher on-time fulfillment. | Provides real-world proof of scalable production through automation and standardized workflows. |

| Best Practices | Develop a design library, standardized color workflows, automate intake/output, train staff, pilot before scaling. | Mitigates risk and accelerates adoption while maintaining quality. |

| Getting Started | Audit current processes, run a pilot, build templates, and then scale with KPI dashboards and ongoing optimization. | Delivers quick wins and a clear path to full deployment. |

Summary

Conclusion

DTF gangsheet builder is a strategic asset for growing apparel brands, enabling scalable production without sacrificing quality. By automating layout, optimizing sheet utilization, and standardizing color workflows, brands can increase throughput, reduce waste, and improve on-time delivery. The showcased case study demonstrates that deliberate implementation—combining templates, automation, and disciplined measurement—can unlock meaningful gains in efficiency and capacity. For brands aiming to grow sustainably, investing in a robust DTF gangsheet builder is a prudent step toward turning demand into reliable, scalable production.