DTF Gangsheet Builder transforms how you plan multi-design transfers by turning scattered art assets into a cohesive sheet strategy, enabling scalable batch layouts that maximize printer uptime, minimize material waste, and deliver repeatable results across diverse garment runs. By streamlining DTF print layouts and simplifying gang sheet design, the tool helps protect critical margins as you tile designs, account for margins and safe zones, and align prints for clean transfers in high-volume productions. Through a structured DTF printing workflow, operators can rely on repeatable templates, precise color management, and predictable registration, which reduces misprints and speeds up the overall cycle from artwork to finished transfers. This approach embodies batch production optimization by enabling fast setup, easy reuse of templates, and consistent quality across orders, so shops can shift from bespoke single runs to efficient, controllable multi-design campaigns. Whether you run a small studio or a larger facility, adopting a DTF Gangsheet Builder mindset delivers faster turnaround, higher throughput, and better scalability for future growth.

From a terminology perspective, this concept resembles a multi-design layout engine that packs several designs onto a single transfer film, converting scattered artwork into a cohesive sheet plan. Viewed through an LSI lens, it aligns with bulk transfer planning, sheet aggregation, and batch-ready templates that support consistent color management and reliable registration across garments. For operators, the focus shifts toward scalable production workflows, efficient space utilization, and repeatable color outcomes across fabrics and runs. Ultimately, the goal remains the same: optimize layouts, minimize waste, and speed up the journey from artwork to wearable products through structured, repeatable processes.

DTF Gangsheet Builder: Enhance DTF Print Layouts for Efficient Batch Production

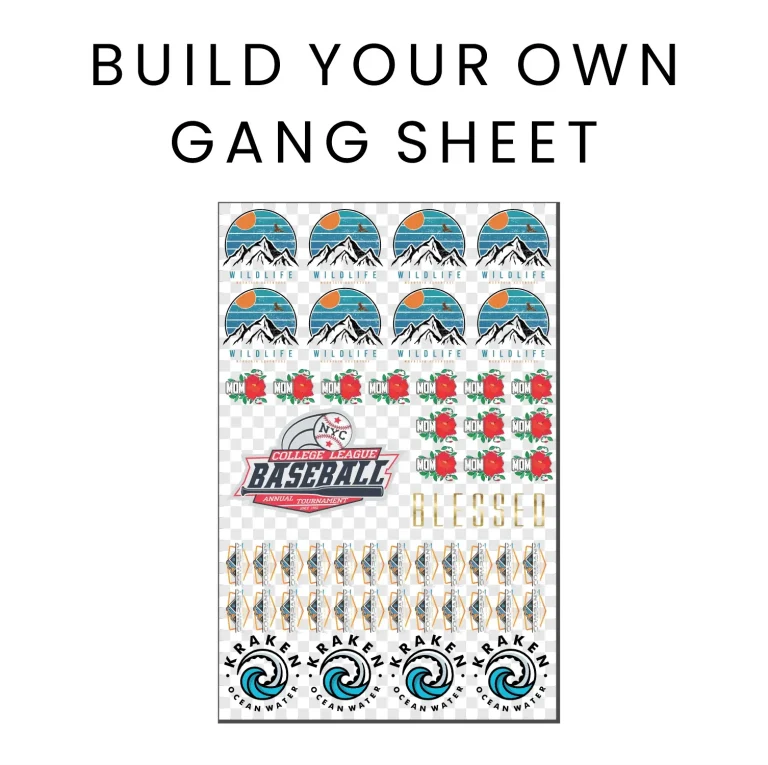

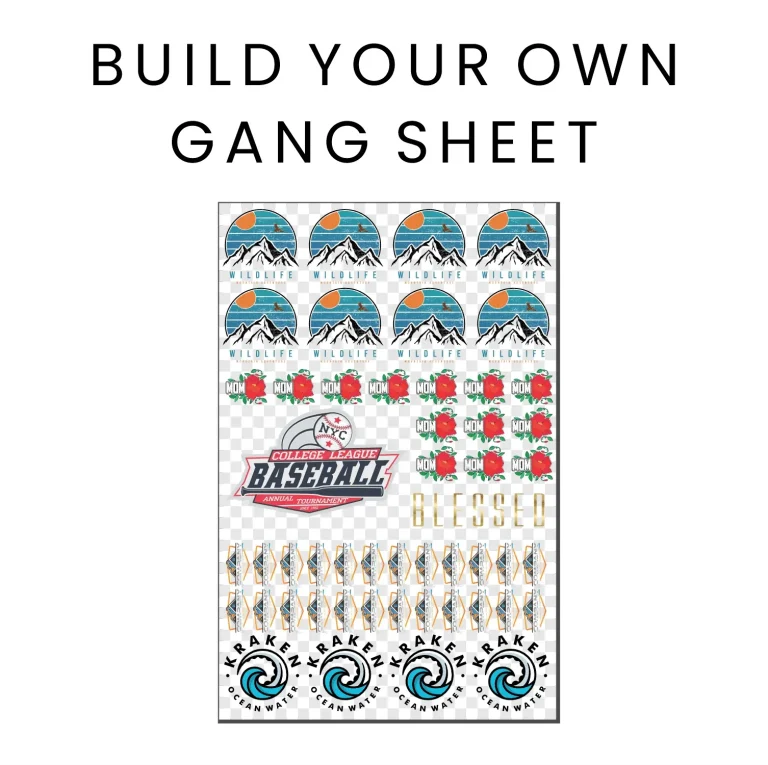

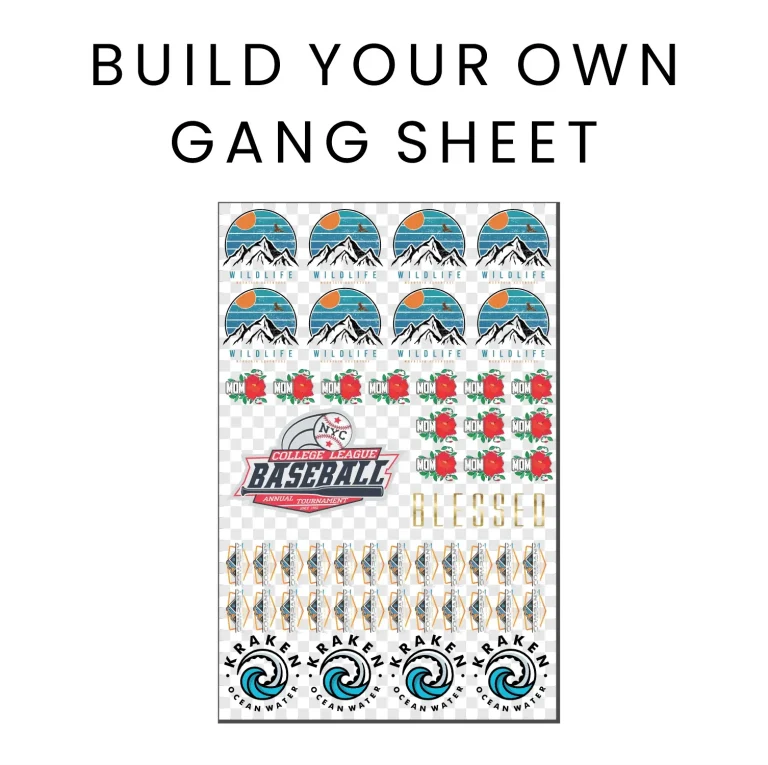

The DTF Gangsheet Builder unlocks efficient batch production by optimizing DTF print layouts. It orchestrates the placement of multiple designs on a single transfer sheet, maximizing printable area while preserving design integrity. By calculating margins, safe zones, and rotation, it reduces material waste and increases the number of designs per run, directly supporting batch production optimization.

Beyond layout geometry, the tool enables template-based workflows that standardize DTF print layouts across similar orders. This repeatability speeds up setup, lowers misprints, and creates a more predictable DTF printing workflow. When white ink underbase and color separations are considered within the gangsheet, you achieve consistent opacity and color accuracy across batches.

In practical terms, teams can measure improvements in throughput and material savings. A well-crafted DTF Gangsheet Builder workflow uses grid-based layouts, clear margins, and preflight to ensure every sheet delivers maximum productivity without compromising design fidelity, driving batch production optimization and faster turnarounds.

DTF Gangsheet Builder in Action: From Gang Sheet Design to a Streamlined DTF Printing Workflow

In practice, the DTF Gangsheet Builder guides gang sheet design decisions—such as grid configuration, orientation, and spacing—so each design aligns with garment seams while preserving color fidelity. This approach supports clean transfers and reliable color reproduction in DTF print layouts and digital transfer printing.

The tool also supports a streamlined DTF printing workflow by turning artwork prep, layout, preflight, and export into a repeatable sequence. By using reusable templates, consistent color profiles, and automated checks, batch production optimization becomes a matter of execution rather than guesswork, resulting in faster setup and fewer reprints.

Advanced users can leverage automation and template libraries to scale up production. Integrating with production management systems enhances visibility into order status and material usage, while standardized gang sheet designs improve consistency across multiple runs, further boosting batch production optimization and throughput.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it support batch production optimization?

A DTF Gangsheet Builder is a tool or workflow that arranges multiple designs on a single DTF transfer sheet. It maximizes the printable area (DTF print layouts) while preserving design integrity, reducing waste, and speeding up batch production optimization. By using repeatable templates and a consistent gang sheet design, it accelerates the DTF printing workflow and aligns with digital transfer printing practices.

How do you leverage DTF print layouts and gang sheet design to improve the DTF printing workflow and batch production?

DTF print layouts and efficient gang sheet design streamline the DTF printing workflow by maximizing sheet usage and preserving color fidelity across designs. Start with the sheet size and a practical grid (e.g., 4×5 or 5×6); apply consistent margins and safe zones; plan orientation/rotation and account for white ink underbase if used. Use templates, run a preflight, and export to the printer. In batch production, this approach reduces setup time, minimizes waste, and speeds digital transfer printing.

| Topic | Key Points |

|---|---|

| What is the DTF Gangsheet Builder? | Tool/workflow to arrange multiple designs on one film sheet to maximize printable area, improve throughput, and reduce waste; enables repeatable batch processes and supports gang sheet design, DTF print layouts, and end-to-end workflow. |

| Core concepts | – Gang sheet design: layout of multiple designs on one sheet, considering margins, spacing, and rotation. – Print layouts (DTF print layouts): precise positioning and alignment to ensure clean transfers and color fidelity. – Batch production optimization: strategies to schedule, combine, and reproduce multiple orders with minimal downtime and waste. – DTF printing workflow: end-to-end sequence from artwork prep and layout to printing, powdering, and heat pressing, emphasizing speed and repeatability. |

| Design considerations | Accounts for printer capabilities, substrate, and finishing. Consider white ink underbase, color separations, and bleed areas. The builder is most valuable when it creates repeatable templates for similar batches, saving time on future projects. |

| Design steps: sheet/grid | Define the sheet size and grid; choose a grid (e.g., 4×5, 5×6) to minimize gaps. Respect margins and safe zones; plan orientation and rotation. Manage color and white ink underbase; use templates/presets; perform preflight checks. |

| Workflow: step-by-step | 1) Artwork collection and standardization. 2) Layout planning in the DTF Gangsheet Builder. 3) Preflight and export. 4) Printing and finishing workflow. 5) Quality control and batch review. |

| Preflight & verification | Run preflight checks for missing images, low resolution, or color profile mismatches. Export the gangsheet layout with the proper ICC profile. |

| Printing and finishing workflow | Print with the correct color profile and calibrated white ink channels if used. Powdering and heat pressing follow the film manufacturer guidelines. |

| Best practices | Use standardized templates, maintain color management discipline, optimize space, implement version control, and document steps for the team. |

| Pitfalls to avoid | Overcrowded designs; inconsistent alignment; suboptimal white underbase; low-resolution files; color mismatches. Use margins and preflight to mitigate. |

| Real-world example | Batch of 40 shirts with 5 designs on a 12×18 inch gangsheet. Some designs rotated; white underbase templates used where needed. Post-printing steps include powdering and heat pressing, yielding minimal waste and fast turnaround. |

| Advanced tips | Templates and automation; variable data handling on gang sheets; save layout templates and color settings; integrate the workflow with production management for visibility and throughput. |

Summary

DTF Gangsheet Builder is a strategic approach to achieving efficient print layouts and scalable batch production. It optimizes DTF print layouts and gang sheet design to enable batch production optimization and a streamlined DTF printing workflow for digital transfer printing. By adopting reusable templates, enforcing consistent color management, and documenting procedures, shops can reduce setup time, increase throughput, and deliver high-quality transfers at scale. Whether you run a small shop or a larger facility, embracing a DTF Gangsheet Builder provides a repeatable, profitable path to faster, more reliable production.