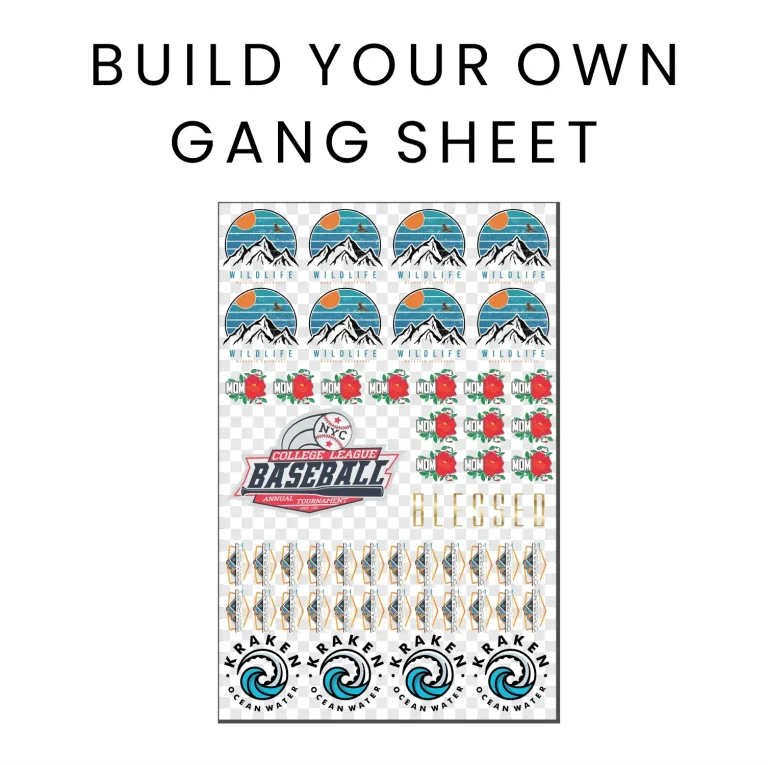

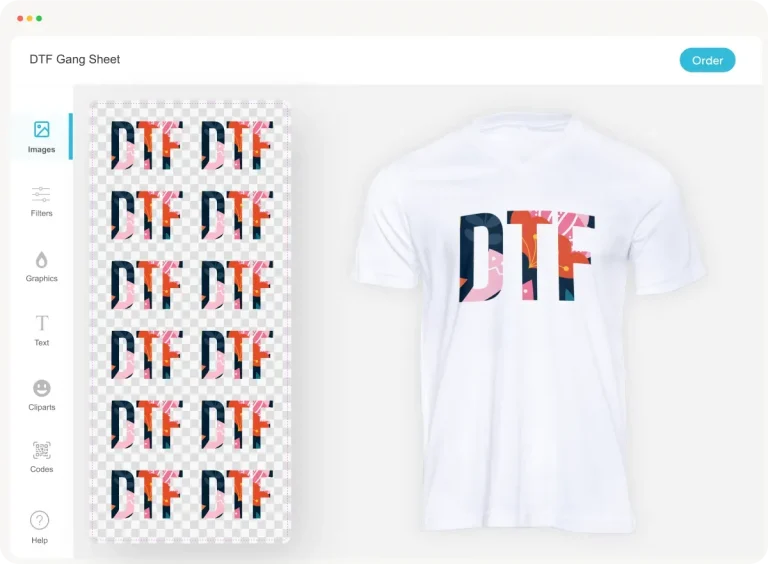

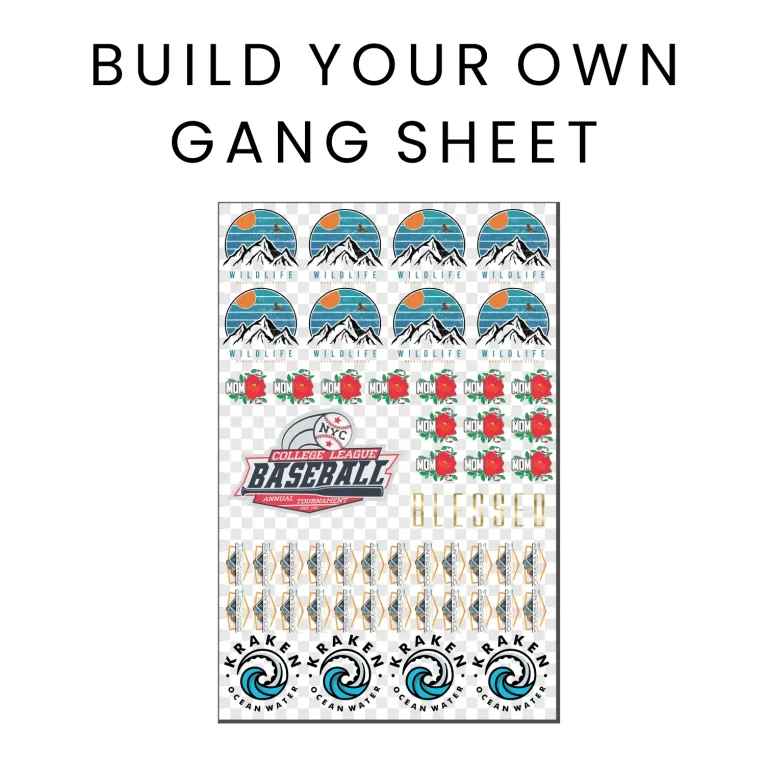

The dtf gangsheet builder is reshaping how shops plan and execute apparel printing, turning scattered designs into a cohesive, production-ready layout. By leveraging DTF printing layouts and gangsheet sizing, you can maximize sheet usage while preserving color accuracy. This tool enables multi-design layouts, letting you fit more artwork on a single sheet without compromising print quality. With built-in layout optimization, it guides spacing, margins, and print sequencing to streamline production workflows. In short, the dtf gangsheet builder translates creative ideas into efficient, scalable outputs from concept to delivery.

Viewed through another lens, this tool acts as a sheet-layout planner, organizing multiple graphics into a single production-ready strip. It supports efficient batch planning by considering print margins, bleed allowances, and color continuity across designs. With this approach, designers and operators can optimize garment-color schemes and sequencing for smoother manufacturing. By focusing on flexible templates and intelligent spacing rules, teams can adapt to different fabric types and sizes without reworking every file. In practice, the system translates creative ideas into a streamlined production workflow that keeps turnaround fast and output consistent.

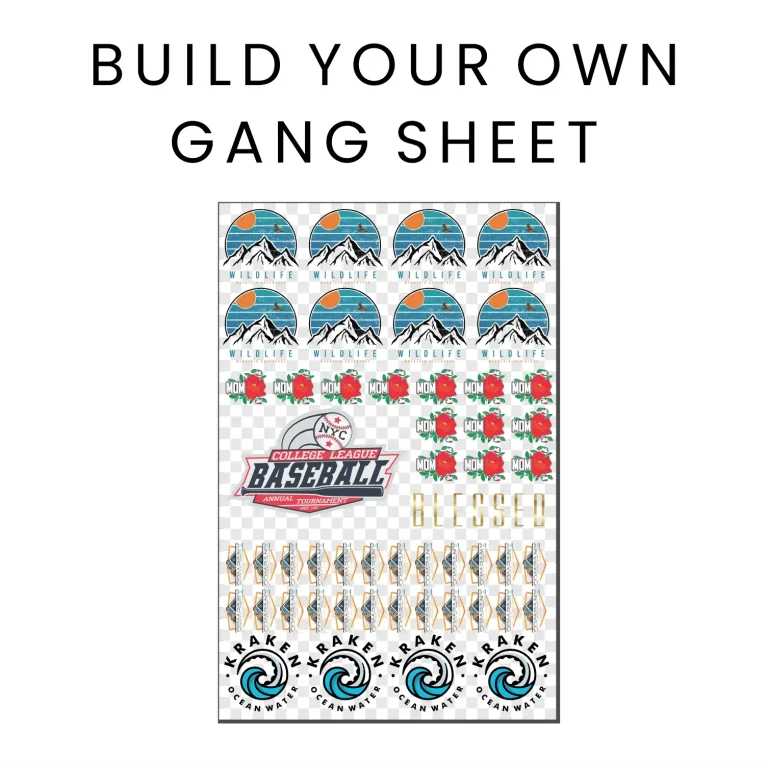

dtf gangsheet builder: unlock efficient multi-design layouts for DTF production

The dtf gangsheet builder is more than a layout app—it’s a design-for-print planning system that considers sheet size, margins, bleed, color separation, and the exact placement of each design, enabling optimized gangsheet sizing and multi-design layouts within DTF printing layouts that fit your production workflows.

By consolidating designs onto a single sheet, you minimize downtime, material waste, and color management challenges. Features like grid-based layouts, safe margins, bleed control, and auto-reflow support layout optimization across the batch, helping you preserve balance and color integrity as you scale.

Practical benefits of multi-design layouts for faster production and consistent color

This approach is especially powerful for production workflows across multiple garment styles, allowing you to schedule curing, finishing, and packing more predictably. With tighter control over gangsheet sizing and precise design placement, you can achieve faster throughput while maintaining high print quality across a batch.

Organizations that adopt the dtf gangsheet builder often report reduced setup changes, lower waste, and easier color management—outcomes that are directly tied to improved DTF printing layouts and robust layout optimization strategies.

Frequently Asked Questions

How can a dtf gangsheet builder improve production workflows and layout optimization for multi-design layouts?

In DTF printing layouts, a dtf gangsheet builder acts as a planning system that considers sheet size, margins, bleed, and precise placement to consolidate multiple designs onto a single sheet, reducing setup time, waste, and press changes. It supports layout optimization by enabling auto-reflow when designs change and providing color management and export-ready files to keep production workflows smooth, fast, and consistent.

What features should you look for in a dtf gangsheet builder to ensure proper gangsheet sizing, bleed control, and efficient production workflows?

Key features include grid-based layouts for easy placement on standard sheet sizes, safe margins and bleed control to prevent cutoffs, automatic reflow when designs are adjusted, and color/print-order management to optimize production workflows. Also ensure support for multiple sheet sizes (gangsheet sizing) and export-ready files compatible with your RIP, enabling efficient DTF printing layouts.

| Aspect | Key Points | Notes / Benefits |

|---|---|---|

| Introduction | DTF printing offers vibrant colors, soft hand-feel, and durable results. As shops scale, efficient production grows; a dtf gangsheet builder becomes essential to plan and arrange multiple designs on a single sheet. The goal is to maximize efficiency, reduce waste, and speed order turnaround without sacrificing print quality or color integrity. | Foundation for workflow: sets context for why gangsheeting matters in DTF. |

| What a dtf gangsheet builder does | Acts as a design-for-print planning system. Considers sheet size, margins, bleed, color separation, and precise placement to consolidate multiple designs onto one sheet. | Reduces downtime, lowers material waste, and streamlines color management across a batch. |

| Why multi-design layouts matter | Reduces the number of print runs needed to complete a collection. For example, 12 designs on two sheets instead of printing each design separately. | Benefits include faster throughput, consistent color handling, lower waste, and improved scheduling. |

| Key features to look for | – Grid-based layouts with easy snapping and alignment for standard sheet sizes (e.g., 12×16, 16×20) – Safe margins and bleed control to prevent cut-off – Automatic reflow when design dimensions change – Color and print-order management to minimize ink bleed and drying time – Export-ready files with embedded proofs, crop marks, and bleed settings compatible with RIP/printer workflows |

Direct impact on design-to-production workflow. |

| Planning your layouts | Best practices before printing: standardize file sizes, define a common safe zone, group designs by color and ink usage, consider rotation/orientation, and plan for variants/overlays. | Sets the stage for efficient gangsheet creation and reduces last-minute resizing. |

| Step-by-step: building a 12-design gangsheet | 1) Gather assets; 2) Choose sheet size; 3) Set up a grid; 4) Place designs; 5) Optimize spacing; 6) Preflight; 7) Export. Sizes mentioned: 12×16, 16×20, A3 equivalents. | Illustrates a practical workflow to maximize sheet utilization and minimize setup changes. |

| Practical tips | – Maintain consistent color management with standardized ICC profiles – Use color-separated previews for pre-press checks – Create a naming convention (e.g., S01_D10_POS03) – Plan production flows (printing, curing, finishing) – Maintain a master library of templates – Test on representative fabrics to verify transfer |

Helps ensure predictable results and faster production. |

| Common mistakes to avoid | – Ignoring safe zones – Inconsistent margins – Overcrowding the sheet – Poor color planning across designs – Skipping preflight checks |

Prevents production issues and rework. |

| Case example: 12-design run | A 3×4 grid on a 16×20 sheet with 0.5 inch outer margin; each design sized to 4×6 inches with 0.25 inch bleed. | Demonstrates reduced setup changes, consistent ink usage, and smoother post-print workflow. |

| Advanced strategies | – Batch design optimization across the sheet – Dynamic layout rules to fill space efficiently – Color-driven sequencing to minimize ink switching – Version control for templates |

Increases automation and repeatability. |

| FAQs | – Do I need special software for a dtf gangsheet builder? – Can I use it for different sheet sizes? – How important is bleed in these layouts? – What if designs come from different designers? |

Most tools support grid layouts, bleed control, preflight checks, and export options; templates can adapt to multiple sheet sizes; bleed is essential; standardize inputs to avoid issues. |

Summary

This HTML table presents a concise, organized snapshot of the core points from the base content about DTF gangsheet builders. It condenses the concepts into easily scannable segments while preserving the key details on what the tool does, why multi-design layouts matter, and best practices for planning, execution, and optimization.