DTF transfers vs screen printing is a common decision for fabric decorators, clothing brands, and hobbyists. Understanding the key differences helps you weigh factors like color fidelity, feel, durability, setup time, and cost. This guide compares Direct To Film transfers with traditional screen printing, highlighting the DTF vs screen printing pros and cons to help you pick the right approach for design needs and budgets. We also touch on the durability of DTF transfers, cost comparison DTF vs screen printing, and guidance on when to choose DTF. Whether your project is small runs or varied artwork, recognizing screen printing limitations vs DTF helps you avoid surprises.

More broadly, the topic can be framed as film based garment transfers versus traditional silk screen decoration. Instead of pushing ink through a mesh screen, this approach uses a printed film and heat to bond designs to fabric. You may see it described as direct to film graphics, digital heat transfer, or ink on film methods, aligning with LSIs for search relevance. For projects where volume, fabric variety, or rapid design changes matter, these terms help you compare run size, durability, and overall feel without getting hung up on process names.

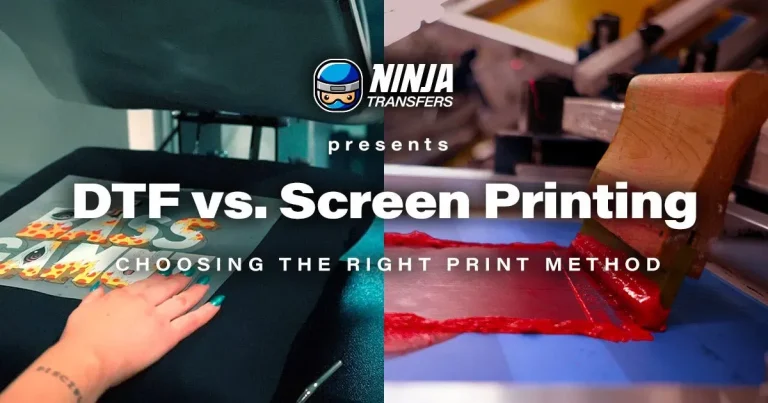

DTF transfers vs screen printing: which is right for your design and budget

Choosing between DTF transfers vs screen printing often comes down to design detail, run size, and budget. DTF transfers excel with complex color photos, gradients, and fine detail, which aligns with the DTF vs screen printing pros and cons discussion. They also offer flexibility for on-demand printing and small batches, reducing upfront art and setup time. However, for large runs with simple color palettes, screen printing can lower per-unit costs due to economies of scale.

Durability and fabric compatibility should influence the choice. DTF transfers can deliver strong color retention when properly cured and washed, addressing the durability of DTF transfers in real-world use. But screen printing may edge ahead on abrasion resistance for some fabrics when using high-quality inks and thorough curing. In addition, screen printing limitations vs DTF are most apparent in multi-color designs where multiple screens are required, driving up setup time and cost.

Cost, durability, and workflow: when to choose DTF

From a cost perspective, DTF often offers lower per-unit costs for small runs, rapid changeovers, and the ability to offer on-demand customization. This aligns with the cost comparison DTF vs screen printing, particularly for limited editions or personalized items. Durability-wise, DTF can deliver robust wash performance when properly cured, but for certain fabrics and large runs, screen printing with high-quality inks can provide longer abrasion resistance and a more permanent hand.

However, for large production runs, screen printing can be more economical, especially when you can leverage a single color layout across many garments. When to choose DTF, weigh design complexity, color count, fabric type, and order volume; testing on real fabrics helps ensure color accuracy and durability. If you are weighing options for when to choose DTF, a hybrid approach—using screen printing for bold color blocks and DTF for detailed elements—can leverage screen printing limitations vs DTF and offer the best of both worlds.

Frequently Asked Questions

DTF vs screen printing pros and cons: which method is best for small runs and detailed designs?

DTF transfers excel for on-demand printing and detailed imagery, offering low setup for small runs and broad fabric compatibility including dark fabrics. They’re ideal when you need quick turnarounds and customization without creating many screens. However, color density can vary for certain tones, the film must be handled carefully to avoid wrinkles, and durability under repeated washing may be less predictable than high-end screen prints. For large runs, screen printing often provides lower per-unit costs and a thicker ink layer. In practice, choose DTF for small, complex or personalized runs and screen printing for large-scale, simple-color designs.

Durability of DTF transfers: how does wash performance compare to screen printing?

With proper curing and aftercare, DTF transfers can withstand repeated wash cycles and maintain color and flexibility. Durability depends on heat/pressure, fabric pre-treatment, and post-press sealing. Screen printing is renowned for wash durability when inks cure correctly, especially with plastisol inks, but performance also depends on fabric type and curing quality. Overall, both methods can be highly durable when executed with quality inks, proper curing, and appropriate care; follow supplier guidelines to maximize lifespan.

| Category | DTF transfers | Screen printing |

|---|---|---|

| Overview / Definition | Direct to Film transfers (DTF) use a PET film substrate with adhesive powder; after curing, the film bonds to fabric with heat and pressure; it works on light and dark fabrics with good color and detail. | Screen printing is a traditional method where ink is pushed through a mesh screen onto fabric; a separate screen is typically needed per color; it yields bold colors and a tangible ink layer. |

| Pros | DTF offers good color reproduction and fine detail; supports complex imagery; lower setup for small runs; versatile across fabrics including dark fabrics; suitable for on-demand printing and quick turnarounds. | Screen printing provides bold, opaque ink with strong wash durability when cured; cost-effective for large runs; robust color saturation. |

| Cons | DTF color density may vary; film handling can cause wrinkles; durability under repeated washing may not always match top quality screen prints; pressing requires precise temperature and time control. | Screen printing requires a separate screen for each color; increases setup time and cost; multiple passes may be needed for complex designs; ink can feel heavier; durability depends on inks, mesh, and curing. |

| Cost & Setup | DTF has lower per unit costs for small runs; moderate initial equipment; ongoing film, adhesives, and ink costs; better for on-demand; larger runs shift cost advantage to screen printing. | Screen printing needs press, screens, squeegees, inks, and curing equipment; higher initial investment; efficient for large runs; single color layouts can print many garments in one pass. |

| Quality & Fabric | DTF offers excellent color reproduction and fine detail; handles gradients and photography well; works on dark fabrics without heavy underprinting; durable with proper cure. | Screen printing offers strong color saturation on lighter fabrics; soft hand; great for natural fibers and white fabrics; ink thickness adds texture. |

| Durability & Wash | DTF is durable with proper heat and care; color and flexibility maintained with proper pre-treatment and post-press sealing. | Screen printing has exceptional wash durability with proper curing; plastisol inks resist wear; long-term durability depends on fabric and curing quality. |

| Choosing the Right Method | DTF is ideal for one-off or small batch orders with detailed imagery; fast turnarounds and less art room for mistakes. | Screen printing is ideal for large runs with straightforward color layouts; lower per-unit cost at scale; robust for simple designs. |

| Use Case Examples | DTF suits fashion brands offering personalized tees; short runs with varied designs. | Screen printing suits bulk merchandise such as event tees, team uniforms, school apparel; best for consistent color blocks and high volume. |

| Tips for Success | Start with high-quality artwork; ensure good color separations; optimize adhesive powder thickness and curing temps. | Choose appropriate mesh count; select inks for fabric; ensure proper exposure and curing; check pigment compatibility. |

| Care & Maintenance | Follow manufacturer care guidelines; educate customers on wash care; avoid high heat. | Follow care guidelines; proper washing and drying to preserve ink; advise on long-term care. |

| Common Myths | DTF can handle high volume with proper equipment; not inherently fragile. | Screen printing is not automatically more durable; depends on inks and curing; both can deliver excellent results when executed properly. |

| Decision Factors / Hybrid Approach | Consider design complexity, color count, units, fabric type, budget, and turnaround; hybrid approaches are possible. | Hybrid approaches can combine both methods to leverage strengths of each for mixed designs. |

Summary

DTF transfers vs screen printing presents a spectrum of options for fabric decorators, clothing brands, and hobbyists. Both methods offer distinct strengths and tradeoffs in color, feel, durability, setup, and cost. For many projects, the decision hinges on design complexity, order size, fabric type, and budget. DTF excels with detailed imagery, vibrant color on dark fabrics, and quick turnarounds for small runs, while screen printing shines in bold color blocks, high wash durability, and efficiency at scale. Consider fabric type, color palette, design complexity, and expected wash cycles. A practical approach is to use a hybrid strategy—employing DTF for detailed elements and screen printing for solid color areas—to maximize quality and production efficiency. By testing on real fabrics and refining artwork and production steps, you can optimize outcomes and deliver consistent, satisfying results for your customers.