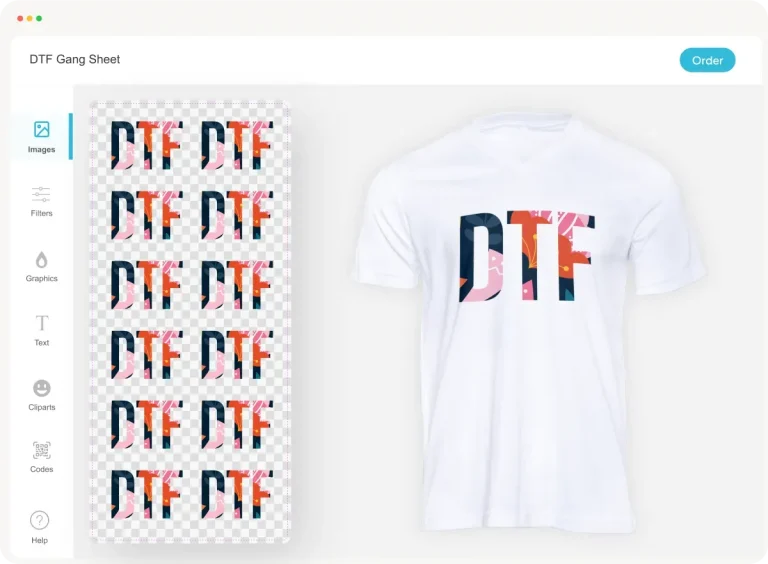

DTF gangsheet builder is changing how apparel brands plan designs by transforming multiple artworks into a single, print-ready sheet that aligns with printer capabilities, media sizes, and production schedules. By optimizing gangsheet layout, this tool ensures efficient use of space, precise margins, and consistent alignment, while also supporting DTF printing formats and ensuring smooth workflow integration. For small-batch printing and large-run production alike, it enables batch processing, reusable templates, and layout optimization to scale operations without sacrificing color accuracy, repeatability, or on-time delivery. In practice, it preserves color fidelity through calibrated profiles, minimizes misalignment across garments, and turns disparate artwork into a cohesive production plan that reduces setup time and accelerates first-run approvals. Whether you run a boutique shop or a facility handling high volumes, mastering this tool saves time and money, lowers waste, and helps you stay competitive across catalog launches, online marketplaces, and seasonal campaigns.

Think of this as a direct-to-film layout optimizer that streamlines prepress work, turning separate artwork into a single, production-ready sheet. Its intelligent layout capabilities and grid-based placement align artwork with printer specs, offering a robust gangsheet layout approach that benefits both small-batch printing and large-run production. The tool supports templates, color management, and batch exports, helping teams standardize processes and reduce color drift across orders. By focusing on efficient space usage, bleed control, and margin safety, it boosts throughput while preserving image fidelity and brand accuracy. For shops expanding from occasional runs to steady catalog launches, such software becomes a cornerstone of a scalable DTF workflow.

DTF gangsheet builder: Mastering layout optimization for small-batch and large-run DTF printing

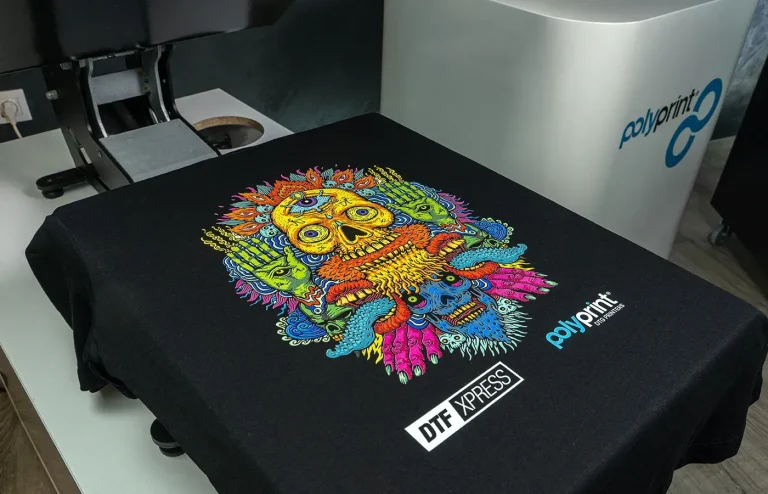

DTF printing relies on smart planning of print surfaces. The DTF gangsheet builder serves as the central tool to arrange multiple designs on one sheet, turning scattered artwork into a single, print-ready file. This enables efficient workflows for both small-batch printing and large-run production by driving layout optimization, controlling margins and bleed, and aligning color management with your printer’s capabilities. When used correctly, it helps maintain consistent alignment across garments and reduces the number of passes, saving time and ink while preserving image fidelity and brand colors.

Key features like grid-based placement, batch processing, and reusable templates empower you to optimize the gangsheet layout for any order. You can adjust spacing and margins, apply bleed correctly, and embed color profiles to keep brand colors consistent across items. This approach supports quick setup for small-batch printing and dense sheet packing for large-run production, all while maintaining color fidelity through ICC profiles and high-resolution artwork suitable for DTF printing.

Optimizing gangsheet layout workflows for consistent color and waste reduction

Efficient gangsheet layout relies on reusable templates, robust color management, and automated workflows. By standardizing layouts and embedding ICC profiles, you ensure that what you preview in the design room mirrors the final DTF print, supporting reliable results across multiple runs. This is the essence of layout optimization in gangsheet creation, whether you’re handling a handful of designs or an established catalog.

Waste reduction and throughput gains come from dense yet safe packing and meticulous documentation. For small-batch printing, templates accelerate setup and minimize waste; for large-run production, standardized color profiles and automated resizing preserve color consistency across hundreds or thousands of garments. Maintaining version history and clear file naming helps you track changes and sustain confidence in your DTF printing workflow.

Frequently Asked Questions

How does the DTF gangsheet builder improve efficiency for small-batch printing?

In DTF printing workflows, the DTF gangsheet builder lets you arrange multiple designs on a single sheet, enabling layout optimization for small-batch printing. With grid-based placement, bleed and margin controls, and embedded color profiles, you can reduce setup time, ink usage, and the risk of misprints while preserving color accuracy across designs.

What features of the DTF gangsheet builder support large-run production and reliable layout optimization?

For large-run production, look for batch processing, reusable templates, and robust layout optimization in the DTF gangsheet builder. These features maximize sheet density and color consistency across thousands of garments. Also prioritize high-resolution exports (PNG/TIF/PDF with embedded ICC profiles) and precise, grid-based placement to keep the gangsheet layout repeatable and scalable across runs.

| Topic | Key Points |

|---|---|

| DTF Gangsheet Builder Overview |

|

| Core Features |

|

| Planning & Layout Steps |

|

| Optimization for Different Run Sizes |

|

| Common Challenges & Best Practices |

|

Summary

DTF gangsheet builder is a pivotal tool for anyone working with DTF printing, enabling efficient design placement, precise color management, and scalable production—from small-batch projects to large-run orders. By understanding layout optimization, mastering the essentials of grid-based placement, and implementing repeatable templates and color calibration, you’ll reduce waste, improve throughput, and deliver consistent results on every sheet. As your operation grows, the gangsheet builder becomes not just a software utility but a core component of your workflow strategy, helping you stay competitive in a fast-moving market. Embrace careful planning, rigorous testing, and ongoing optimization, and your DTF printing process will be smoother, faster, and more reliable than ever before.