DTF transfers are reshaping garment decoration by enabling vibrant, durable designs across a wide range of fabrics. As 2025 approaches, the field is guided by DTF printing trends 2025, direct-to-film technology, and ongoing improvements in white ink performance. This article explores how advances in DTF transfer techniques and 2025 apparel printing expand design options for brands, hobbyists, and print shops. New materials, faster workflows, and more compatible DTF printer compatibility options are redefining production efficiency. Understanding these dynamics helps you plan on-demand runs with reliable results across diverse fabrics.

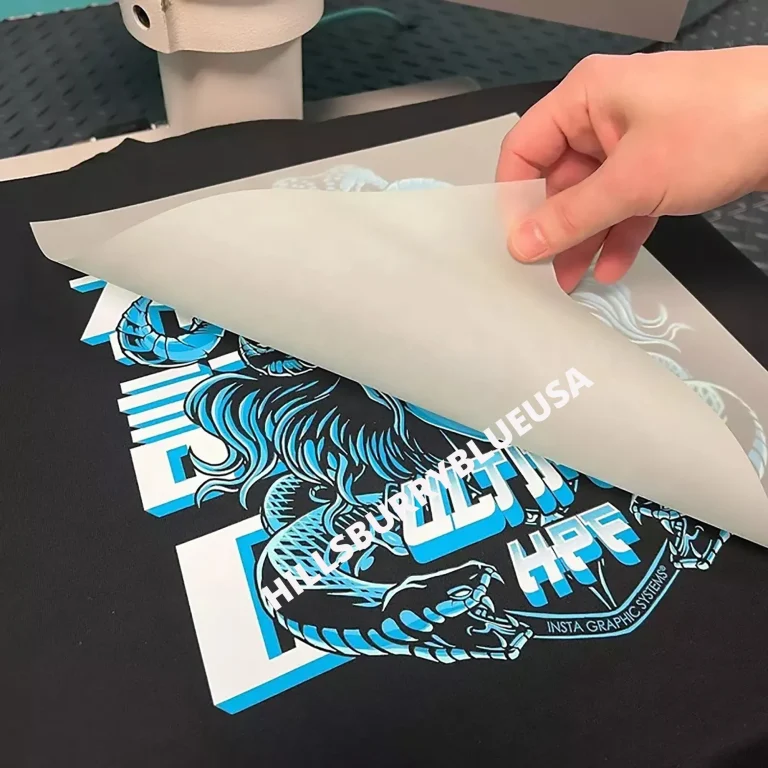

Alongside the shorthand term, this film-based decoration method leverages a direct-to-film process to transfer full-color artwork onto textiles. Viewed through an LSI lens, related concepts like film-based transfer, ink-on-film systems, and heat-press activation help search engines connect this topic with broader topics in apparel printing. The approach enables on-demand customization, rapid turnarounds, and scalable production across diverse substrates—from cotton blends to performance fabrics. By using these connected concepts, designers and suppliers can discuss results in ways that align with industry terminology and user intent.

The Rise of DTF Transfers in 2025: Key Trends and What They Mean

DTF transfers are at the forefront of garment decoration, delivering vibrant, durable designs across a broad range of fabrics. The 2025 landscape, described in terms of DTF printing trends 2025, emphasizes brighter whites, sharper color saturation, and improved opacity on dark textiles, enabling more confident design choices for brands and hobbyists alike. As direct-to-film technology matures, on-demand workflows and rapid production cycles become the norm, reshaping how products move from concept to consumer. This shift is redefining expectations for 2025 apparel printing, with durability and wash performance now driving both aesthetic outcomes and long-term value.

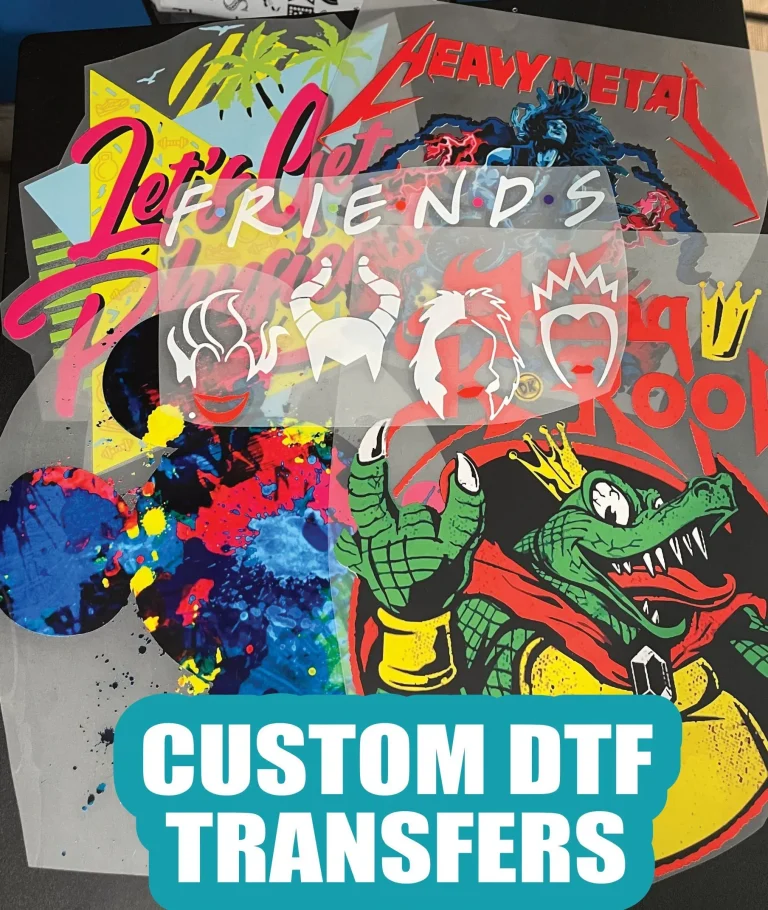

Beyond color quality, the market is embracing flexible production models that support limited editions, fast-turnaround drops, and customized merch. DTF transfer techniques empower designers to push bold imagery, layered compositions, and photo-realistic details on diverse fabrics—from cotton blends to performance synthetics. With e-commerce expanding, the ability to produce high-quality, customized designs quickly becomes a competitive differentiator, influencing how teams, schools, and boutique brands plan product cycles and marketing releases.

Advancements in Direct-to-Film Technology: Equipment, Inks, and Curing

In 2025, the footprint of the hardware and inks powering DTF transfers has expanded, bringing better reliability and color fidelity to more operations. New or upgraded printers paired with higher-quality white inks deliver brighter colors and improved opacity on dark fabrics, while advances in white ink stability and curing reduce cracking and bleeding during washes. Faster nozzle reliability and higher print speeds shorten production cycles, which is crucial for on-demand workflows and tight drop timelines.

Inks are evolving toward enhanced wash durability, reduced cracking on stretch fabrics, and tighter color consistency across batches. Some formulations are optimized for lower-emission curing methods, improving safety and cutting energy use in shop environments. Direct-to-film technology now often includes coatings and pre-treatments that minimize ghosting and promote more uniform ink deposition. Together, these improvements push DTF printing toward faster, more reliable production without sacrificing image quality, enabling more efficient adoption of DTF transfer techniques across a wider range of applications.

Materials Mastery: Films, Adhesives, and Substrates for Every Fabric

Film and adhesive systems continue to mature, delivering sharper halftones, smoother gradients, and stronger adhesion across textiles—from traditional cottons to modern performance fabrics. Engineering advances in DTF films help inks bond more consistently, enabling better drying times and reduced a ghosting risk on complex color jobs. This broader substrate compatibility supports designers exploring new color palettes and fabric blends without retooling the production line.

Adhesives are being tuned for enhanced flexibility on stretch fabrics, reducing delamination in activewear and ensuring long-lasting results on performance garments. Surface treatments on films further improve ink bonding and shorten drying times, which is especially valuable for high-volume shops that run hundreds of transfers per day. As materials science evolves, designers can experiment with more fabric types and colorways, confident that the transfer will perform across multiple washes and environments.

Color Management and RIP Tools: Ensuring Consistency Across Runs

Color management remains a critical factor in achieving consistent results across batches. The 2025 landscape features continued refinement of RIP software, driver profiles, and ICC-based color calibration tailored to DTF transfers, helping shops reproduce exact colors from digital artwork. Gamma correction, soft-proofing, and standardized printer profiles reduce color drift between runs and machines, providing predictable outcomes on a variety of fabrics.

Automation features are becoming more prevalent, including queue management, automatic imposition, and integrated ink level monitoring. These tools streamline production, minimize human error, and enable operators to scale operations without sacrificing quality. For designers, improved color management translates into more reliable color fidelity across substrates, ensuring that a brand’s visual identity remains consistent from one garment to the next.

Applications and Business Models in 2025: From Custom Merch to Team Gear

DTF transfers have broadened beyond small studios into sports teams, schools, boutique brands, and lifestyle apparel lines. The ability to produce high-detail, full-color designs on demand makes DTF highly attractive for limited editions, event-specific releases, and rapid-turn custom merchandise. In this evolving landscape, businesses are leveraging on-demand capabilities to test ideas quickly, reduce inventory risk, and deliver personalized products that resonate with end customers.

A growing trend is the use of layered designs and multi-image motifs, enabling complex effects that were difficult or costly with traditional screen printing. Shops can combine several transfers on a single garment to create depth and motion, while e-commerce platforms enable fast digital-to-garment fulfillment. As brands seek faster time-to-market and more individualized offerings, DTF printer compatibility with existing workflows and RIPs becomes a deciding factor for ROI and scalability.

Sustainability, Safety, and Compliance in DTF Printing

As consumer demand for greener products grows, DTF transfers are moving toward more sustainable practices. Inks with lower volatile organic compound (VOC) content, reduced waste from registration sheets, and more efficient curing contribute to greener production. Many suppliers now offer traceability data for inks and films, helping shops communicate environmental and safety considerations to customers and partners.

From a safety and operations perspective, improved handling instructions and less hazardous formulations enable smaller teams to operate more safely. For businesses, adopting eco-friendly materials can differentiate a brand in markets where sustainability matters. As the ecosystem matures, adherence to best practices and clearer quality benchmarks will help customers compare providers, ensuring consistent performance alongside a reduced environmental footprint.

Frequently Asked Questions

What are the key drivers behind DTF printing trends 2025, and how does printer compatibility influence direct-to-film technology choices for DTF transfers?

DTF printing trends 2025 are driving brighter colors, improved white ink stability, faster curing, and more reliable performance on a wider range of fabrics. Printer compatibility matters because not all devices handle high-opacity white inks or specific curing methods equally well. When choosing equipment, verify white ink coverage, RIP support, nozzle reliability, and seamless integration with your heat-press workflow to ensure durable DTF transfers.

How have DTF transfer techniques evolved for 2025 apparel printing, and what impact does this have on fabric performance and color quality?

DTF transfer techniques in 2025 emphasize sharper halftones, smoother gradients, and stronger adhesion across cotton to synthetics. Advances in surface treatments and inks reduce ghosting and cracking on stretch fabrics, while faster curing supports on-demand production. The result is brighter, more durable colors and consistent outcomes across diverse fabrics for 2025 apparel printing.

What role do inks, films, and adhesives play in direct-to-film technology advancements shaping DTF transfers in 2025?

In direct-to-film technology, advanced white inks with improved wash durability and stretch performance work with engineered DTF films and flexible adhesives to boost adhesion and print reliability. New surface treatments enhance ink bonding and shorten drying times, enabling high-volume production and consistent results across garments and colors in 2025.

What should a shop consider for DTF printer compatibility when planning for 2025 apparel printing workflows and increased production?

When planning for 2025 apparel printing, prioritize DTF printer compatibility with your heat-press, RIP software, and inks. Look for reliable white ink performance, compatible curing methods, easy media handling, and scalable throughput. Align printers, films, and adhesives to minimize retooling and maximize on-demand capacity for DTF transfers.

How is sustainability addressed in 2025 DTF transfers, and how does direct-to-film technology contribute to safer, greener apparel printing?

Sustainability in DTF transfers comes from lower VOC inks, reduced waste, and more energy-efficient curing. Direct-to-film technology providers are increasingly offering traceability data for inks and films, helping brands communicate safety and sustainability. Smarter curing and material efficiency also lower energy use while maintaining durability.

What practical steps can studios take to implement DTF transfer techniques effectively and manage color, while staying aligned with 2025 trends and printer compatibility?

Begin with a small pilot of on-demand DTF transfers to test print quality, wash durability, and color management. Invest in color-management tools, ICC profiles, and RIP training. Verify printer compatibility with your current workflow, test new films and adhesives on your fabrics, and plan a scalable ramp-up as you align with 2025 printing trends.

| Topic | Key Points |

|---|---|

| Introduction | DTF transfers have reshaped garment decoration with vibrant, durable designs across many fabrics; by 2025, innovations are changing how brands, hobbyists, and print shops approach direct-to-film technology. |

| Technological Advances in DTF Printing Equipment and Inks | New/updated printers and white inks deliver brighter colors and better opacity on dark fabrics; improved white ink stability and curing reduce cracking/bleeding; faster print speeds; inks emphasize wash durability, stretch performance, color consistency, and lower-emission curing. |

| Materials and Substrates: Films, Inks, and Adhesives | DTF films enable sharper halftones and smoother gradients with stronger adhesion across cotton, blends, and synthetics; adhesives optimized for stretch fabrics; surface treatments improve ink bonding and drying times; broader substrate compatibility reduces retooling. |

| Workflow, Color Management, and RIP Technology | Refined RIP software, ICC profiles, gamma management, and color calibration reduce color drift; automation (queue management, auto-imposition, ink monitoring) streamlines production and supports scaling while maintaining quality. |

| Applications and Market Trends: Who’s Winning in 2025 | DTF transfers are expanding beyond small shops into sports teams, schools, boutique brands, and lifestyle lines; on-demand full-color, high-detail designs enable limited editions and event-specific releases; layered designs and multi-image motifs are gaining popularity. |

| Sustainability, Safety, and Compliance | Lower VOC inks, reduced material waste, and efficient curing support greener production; traceability data and safer handling improve safety and transparency; eco-friendly materials become differentiators for sustainability-conscious customers. |

| Business Implementation & The Future Beyond 2025 | Practical steps include evaluating printers/inks for reliability and wash durability, testing films/adhesives, investing in color management, and running pilots; expect continued automation, data-driven color optimization, and standardized quality benchmarks. |

Summary

DTF transfers are at the forefront of modern garment decoration, driven by rapid advances in printing technology, film and adhesive chemistry, and smarter workflows. The 2025 trends point to faster production, broader substrate support, richer color expression, and a stronger focus on sustainability. For shops, brands, and makers, embracing these developments unlocks new design possibilities, reduces time-to-market, and improves profitability. Staying informed about white ink performance, direct-to-film innovations, and printer compatibility will help you capitalize on the evolving DTF transfers landscape and ride the next wave of opportunities.