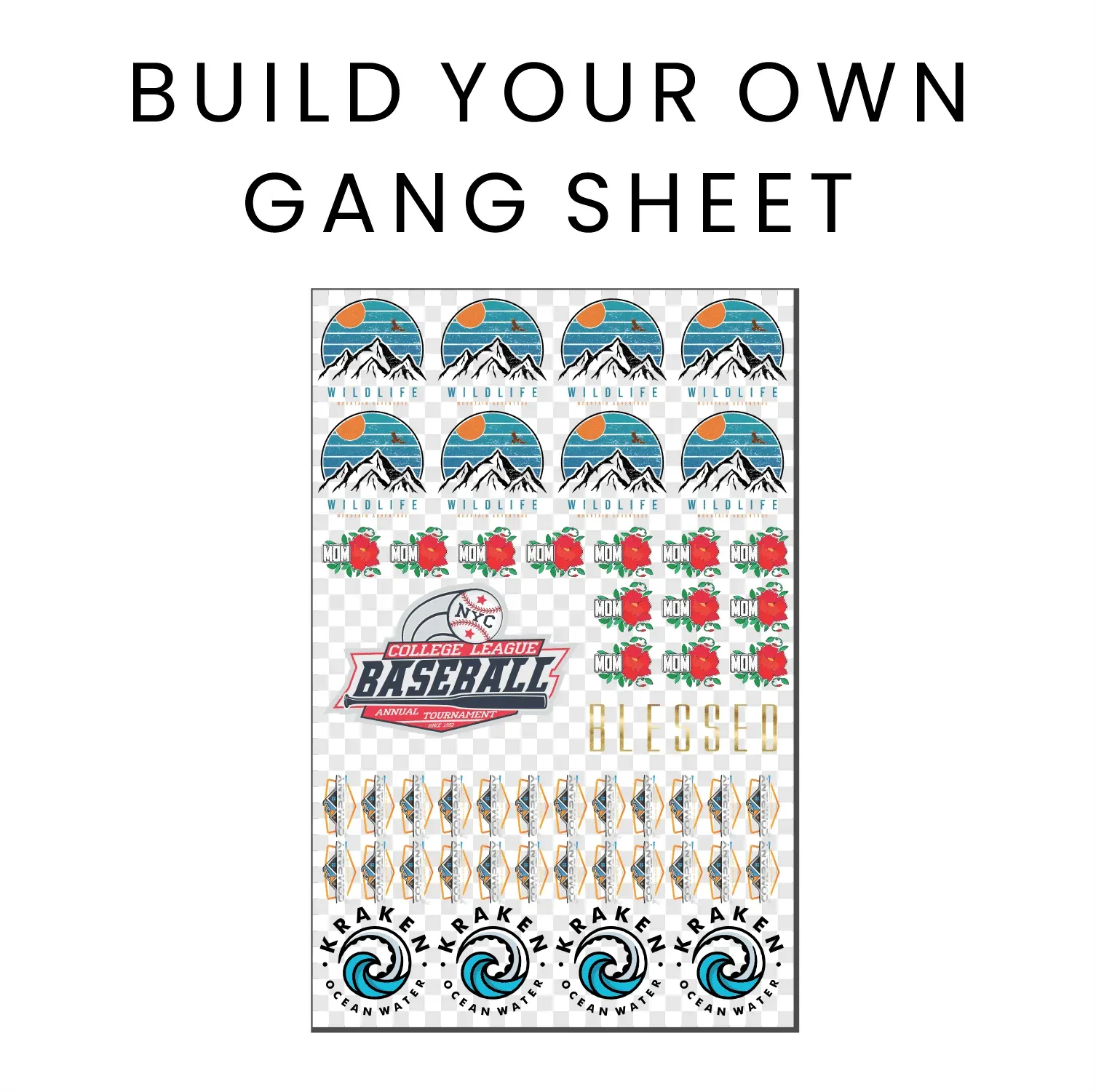

The DTF Gangsheet Builder is a game-changer in the realm of custom apparel printing, particularly within the innovative area of DTF printing. By leveraging the gangsheet technique, this builder enables creators to print multiple designs directly onto one sheet, dramatically enhancing both efficiency and cost-effectiveness in the design preparation process. No longer do you need to settle for single prints; with the DTF Gangsheet Builder, you can create a cohesive collection of designs ready for direct to film printing. This allows users to maximize their creative potential while minimizing waste, making it an essential tool for anyone in the apparel printing industry. Get ready to unlock new levels of productivity and creativity by mastering this unique technology.

When it comes to modern methods of printing, the DTF Gangsheet Builder stands as a pivotal resource for those engaged in the art of fabric decoration. Utilizing direct to film printing, this innovative builder brings multiple graphics together on a single gangsheet, streamlining the entire apparel printing process. The gangsheet method not only reduces material waste but also allows for efficient design preparation and execution. This multifaceted approach to printing revolutionizes how designers and entrepreneurs tackle their projects, enabling them to produce high-quality designs that appeal to a broad audience. Embrace this technology and elevate your production capabilities with the insights provided in this guide.

Exploring the Benefits of DTF Printing

Direct to Film (DTF) printing offers a range of benefits that set it apart from traditional printing methods. One of the primary advantages is its versatility, as DTF can be used on a wide variety of textiles, including cotton, polyester, and blends. This flexibility makes it an ideal choice for customizing apparel, as it allows businesses and individuals to cater to diverse customer preferences. Furthermore, DTF printing produces vibrant colors and detailed designs, making it well-suited for intricate artwork and logos.

In addition to its versatility, DTF printing is known for its efficiency in production. The gangsheet technique enables multiple designs to be printed on a single sheet, which conserves resources and minimizes printing time. This not only reduces costs but also streamlines the workflow, allowing creators to take on more projects without sacrificing quality or detail. The fast curing process of DTF designs further enhances its appeal, making it suitable for businesses looking to fulfill urgent orders without compromising on quality.

Mastering DTF Design Preparation Techniques

Effective design preparation is critical to achieving great results in DTF printing. The use of graphic design software, like Adobe Illustrator or CorelDRAW, allows you to tailor your artwork specifically for the DTF process. Ensuring your designs are saved in PNG format helps maintain transparency, which is crucial for smooth transfers onto fabrics. Additionally, setting your design resolution to 300 DPI will guarantee that your final prints will be sharp and vivid, elevating the professionalism of your custom apparel.

Spacing is another vital aspect of DTF design preparation, especially when utilizing the gangsheet method. Adequately spacing your designs—about 0.5 to 1 inch apart—prevents overlap and ensures clean cuts when separating each design post-printing. This meticulous preparation stage is what allows DTF printers to produce high-quality, vibrant, and crisp designs, enabling businesses to meet their clients’ expectations effectively.

Setting Up Your DTF Gangsheet for Success

Setting up your gangsheet correctly is essential for optimizing the DTF printing process. Start by loading all necessary designs into your graphic design software and arranging them thoughtfully within the dimensions of your chosen gangsheet size, whether it’s A3 or A4. Using grid lines can assist with alignment and symmetry, ensuring that your designs fit snugly within the printable area while leaving adequate space to avoid any unwanted overlaps during the printing process.

Another crucial consideration is adjusting your design dimensions appropriately. Not only should you focus on minimizing waste, but you should also take into account the intricacies of your designs to ensure they are easily readable and visually appealing. By properly preparing your gangsheet layout, you lay the foundation for a successful print run, which ultimately translates to higher quality apparel products.

The Importance of Printer Settings in DTF Printing

Optimizing printer settings is a key component of successful DTF printing. Every DTF printer has specific requirements based on the type of film used, so it’s imperative to refer to the manufacturer’s guidelines for setup. This includes adjusting ink saturation, print speed, and resolution settings to match the materials you are using. Properly setting up your DTF printer is essential to avoid common pitfalls, such as colors appearing muted or prints coming out blurry.

Conducting a test print can significantly impact the outcome of your final products. Printing a smaller gangsheet as an initial test allows you to verify color accuracy and confirm the print quality before committing to a full print run. This proactive approach helps catch potential issues early, ensuring that the designs you transfer onto garments are of the highest standard.

Curing Techniques for Optimal Print Durability

Curing is a critical step in the DTF printing process, as it solidifies the inks onto the film and prepares them for transfer onto fabric. Achieving the right curing temperature and duration is vital to ensure durability and color vibrancy. Typically, the curing process requires a heat press set to around 350°F (175°C) for 10-15 seconds, following the manufacturer’s specifications. Proper curing not only enhances the quality of the final product but also increases the durability of the designs, allowing them to withstand washes without fading.

Additionally, attention to even heat distribution during the curing step is crucial. Uneven heat can lead to inconsistent bonds between the ink and film, resulting in peeling or fading designs. Regular maintenance of your heat press and ensuring it is calibrated correctly can help prevent these issues, leading to uninterrupted production and high-quality outputs.

Best Practices for Successful DTF Printing

Following best practices is essential for achieving consistent results in DTF printing. One important recommendation is to conduct test prints prior to large production runs. This allows for adjustments to be made before committing to extensive printing, ensuring that all elements—such as colors, sizes, and design placement—are accurate. It’s an effective way to minimize waste, save time, and reduce costs associated with reprints.

Another key practice is maintaining your software and equipment. Regular updates to your graphic design software and DTF printer not only unlock new features but also improve overall performance and printing quality. Additionally, using quality materials—such as premium inks and films—will produce better results. Storing printing supplies in optimal conditions is also important to prevent degradation, ensuring you receive the best performance from your DTF equipment.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in Direct to Film (DTF) printing that allows multiple designs to be printed on a single sheet. This gangsheet technique optimizes material usage, reduces printing costs, and ensures high-quality apparel printing by enabling intricate designs to coexist without waste.

How can I prepare my designs for the DTF Gangsheet Builder?

To prepare your designs for the DTF Gangsheet Builder, utilize graphic design software like Adobe Illustrator or CorelDRAW. Ensure your designs are saved in PNG format with a transparent background, and maintain a resolution of at least 300 DPI for crisp, vibrant prints. Proper spacing between designs is also crucial to avoid overlaps during printing.

What are the essential steps to printing using the DTF Gangsheet Builder?

The essential steps to printing with the DTF Gangsheet Builder include: 1. Design preparation with graphic software, 2. Setting up your gangsheet in the software, 3. Printing with a DTF printer, and 4. Curing the print using a heat press to bond the inks to the DTF film.

What are some best practices for using a DTF Gangsheet Builder?

Best practices for using a DTF Gangsheet Builder include conducting test prints to check color accuracy, regularly updating your design software and printer settings for optimal performance, and carefully spacing designs on the gangsheet to ensure clean transfers to garments without overlap.

Can I use any printer for my DTF Gangsheet Builder projects?

No, you cannot use just any printer for DTF Gangsheet Builder projects. You need a specialized DTF printer which is designed to handle the film’s specific thickness and coating, ensuring high-quality prints suitable for apparel printing.

Where can I find resources to improve my skills with the DTF Gangsheet Builder?

To enhance your skills with the DTF Gangsheet Builder, look for online tutorials and blogs from sources like Printavo, YouTube channels focused on DTF printing techniques, and community forums like T-shirt Forums or Reddit’s r/printing to gain tips and advice from experienced users.

| Step | Description |

|---|---|

| 1. Design Preparation | Use graphic design software to create designs saved in PNG format with a transparent background. Ensure high resolution (300 DPI) for sharp prints. |

| 2. Setting Up the Gangsheet | Load designs into software, spacing them correctly (0.5 to 1 inch apart). Adjust dimensions to fit an A3 or A4 sheet. |

| 3. Printing | Optimize printer settings for film type and conduct test prints to verify color accuracy before large prints. |

| 4. Curing | Cure printed films using a heat press at 350°F for 10-15 seconds, ensuring even heat application. |

| 5. Cutting and Transferring | Carefully cut designs from the gangsheet and use a heat press to transfer them onto garments, ensuring accurate alignment. |

Summary

The DTF Gangsheet Builder is a pivotal tool for anyone eager to thrive in the custom apparel industry. By mastering the steps outlined in this guide, including design preparation, setup, printing, curing, and transferring, you will unleash your creative potential while enhancing efficiency in the printing process. With the right resources and best practices, you can significantly reduce waste and achieve high-quality, vibrant prints that stand out. Embracing the DTF gangsheet building technique is your gateway to turning unique design ideas into reality, setting you on a path to success in the competitive market of custom apparel.