DTF supplies form the backbone of the innovative Direct-to-Film (DTF) printing process, which has rapidly gained popularity among textile professionals and enthusiasts alike. This unique printing method utilizes specialized materials, including DTF printers and adhesive powder for DTF, to deliver high-quality, durable prints on various fabrics. The seamless transfer of vibrant designs from film to fabric is made possible by these essential supplies, enabling custom creations that stand out. As businesses and crafters embrace DTF printing, understanding the importance of selecting the right supplies becomes crucial for achieving optimal results. Dive into the world of DTF and discover how these supplies are revolutionizing the fabric printing landscape.

Exploring the realm of Direct-to-Film (DTF) resources reveals a treasure trove of materials pivotal for fashioning stunning fabric prints. The necessary items range from advanced printers tailored for DTF technology to innovative transfer films that ensure impeccable design application. Additionally, bonding agents such as adhesive powder and the heated pressure of a heat press for DTF applications play critical roles in the overall printing process. As the demand for personalized and high-quality printed products continues to rise, understanding these key supplies can empower creators to harness the full potential of this groundbreaking printing method. The integration of these components not only enhances the usability of DTF printing but also fosters a community that thrives on creativity and shared knowledge.

Understanding the DTF Printing Process

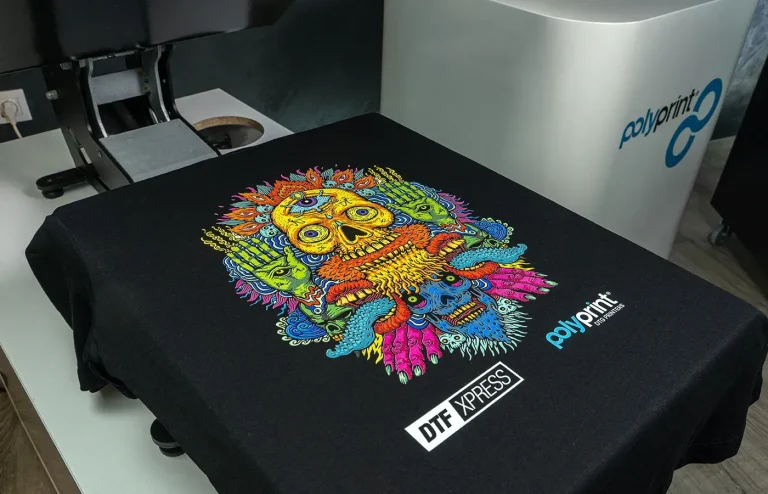

DTF printing, or Direct-to-Film printing, is an innovative method that allows for the transfer of intricate designs onto various fabrics. The process begins with high-resolution digital printing on a special coated film, using proprietary water-based inks that ensure vivid colors and precise details. After printing, an adhesive powder is sprinkled onto the wet ink, which is then cured to form a durable bond. This film is placed on the fabric, where high heat from a heat press activates the adhesive, transferring the printed design seamlessly onto the fabric. This method is particularly advantageous due to its versatility, as it works well with a wide range of textiles, from cotton to more complex blends, making it ideal for both casual and commercial use.

Conveniently, the DTF printing process matches the speed and efficiency of traditional printing techniques while offering superior print quality and durability. Unlike screen printing, DTF does not require extensive setup time and allows for short runs without sacrificing quality. DTF printers are specifically designed for this application, ensuring that the ink formulation and settings are optimized for best results. As more users become aware of the benefits of DTF printing, adoption of this cutting-edge technique is expected to grow within the textile industry.

Essential Supplies for DTF Printing Success

To thrive in the DTF printing landscape, it is vital to equip oneself with the essential supplies that will enhance the output quality and streamline the process. Primary among these are specialized DTF printers that are tailored for the complexities of DTF applications. These printers utilize advanced technologies to handle the unique formulations of inks and powders, providing consistent results. Additionally, the quality of transfer films plays a significant role in ensuring optimal transfer to fabrics. The right film can dramatically impact the vibrancy and durability of the final prints.

Equally important are adhesive powders, which are integral to the DTF printing process. This material acts as a bridge between the printed designs and the fabric during the heat transfer phase. It’s crucial to choose high-quality adhesive powders, as these influence adherence and washability of the prints. Lastly, a heat press is indispensable, allowing for the application of even heat and pressure necessary for successful transfers. By investing in quality supplies, users can significantly elevate their DTF printing outcomes, resulting in distinctive products that stand out in a competitive market.

Recent Innovations in DTF Printing Supplies

The DTF printing industry has seen remarkable innovations in recent years, particularly in the realm of inks and films. Major manufacturers have introduced specialized DTF printers to improve the printing process’s robustness and efficiency. Brands like Epson and Mimaki are leading the charge with their latest models designed to maximize ink adhesion and enhance color vibrancy, making the printing process more accessible to small businesses and individual creatives alike. The advancements in ink technology, including formulations that increase washability, mean that DTF prints retain their lively appearance even after multiple washes, a significant concern for consumers.

Furthermore, innovations in transfer films now cater to a plethora of fabric types beyond traditional uses, widening the scope of design applications. As the industry evolves, users can expect films designed for specialty materials, such as athletic wear, work uniforms, and home goods, all of which require different adhesion properties and durability standards. The influx of new suppliers into the market continues to drive competition, ultimately benefiting customers with more choices and lower prices for high-quality materials.

Understanding Costs and Pricing Trends in DTF Printing

While entering the DTF printing space may involve significant initial investment in equipment and supplies, understanding the pricing trends is crucial for long-term success. The cost-benefit analysis of DTF printing reveals that, although the upfront expenses can be higher than traditional methods like screen printing, the efficiency and reduced costs per unit can lead to greater profitability. With the increase of supply options available, many businesses find that the long-term savings from lower production costs compensates for their initial expenditure.

Additionally, the declining costs of essential DTF supplies, such as high-quality transfer films and adhesive powders, have made DTF printing increasingly feasible for start-up businesses and hobbyists alike. As more manufacturers enter the market, competition contributes to more favorable pricing, enticing more users to try this innovative printing technique. By keeping an eye on pricing trends and choosing the right suppliers, entrepreneurs can optimize their investment and reap the rewards without compromising quality.

Creative Applications and Design Capabilities of DTF Printing

DTF printing offers remarkable versatility, allowing users to explore a myriad of creative applications. This technique is not limited to apparel; it extends to various materials, including home textiles, promotional products, and custom accessories. For instance, entrepreneurs can produce dazzling designs for T-shirts, tote bags, or even unique home decor items. The ability to create detailed, high-resolution images makes DTF a favorite among artists and designers who are eager to express their creativity on fabric.

In addition to its fabric versatility, advancements in design software have significantly enhanced the artistic capabilities of DTF printing. New tools are simplifying the creation and manipulation of intricate designs, making it easier for users to realize their visions. Whether one is an amateur looking to personalize gifts or a business aiming to expand its product offerings, DTF printing technology empowers creators to bring their ideas to life seamlessly and efficiently.

Engaging with the DTF Printing Community and Education Resources

One of the most enriching aspects of DTF printing is the vibrant community that exists to support newcomers and seasoned professionals alike. Numerous online forums, blogs, and social media groups are dedicated to DTF printing, sharing tips, tutorials, and best practices. Engaging with these platforms allows users to learn from the experiences of others, troubleshoot issues, and stay updated on the latest trends and technologies in the industry. Websites like Printavo and The Print Life provide a treasure trove of resources that the community can leverage to enhance their skills and knowledge.

Moreover, educational resources have proliferated, offering courses and videos focused on DTF printing techniques and best practices. Workshops and online tutorials not only teach the technical aspects of the process but also inspire creativity and innovation. By tapping into these educational opportunities, users can build a solid foundation in DTF printing, boosting their confidence to experiment and ultimately achieve stunning results that wow audiences.

Frequently Asked Questions

What are the essential DTF supplies for printing high-quality designs?

To achieve high-quality results in DTF printing, essential supplies include DTF printers, specialized transfer films, adhesive powder for DTF, and a reliable heat press for DTF. These components work together to ensure successful design transfers onto various fabrics.

How does adhesive powder for DTF enhance the printing process?

Adhesive powder for DTF is crucial as it bonds the printed design to the fabric. When applied correctly, this powder ensures that the design adheres under heat and pressure, creating durable and vibrant prints that withstand washing.

What is the role of a heat press for DTF printing?

A heat press for DTF printing is essential for transferring designs from the transfer film to fabric. It applies the necessary heat and pressure that activates the adhesive powder, ensuring a successful and lasting transfer.

What types of fabrics can DTF printing be used on?

DTF printing is versatile and can be used on a wide range of fabrics, including cotton, polyester, and blends. This makes it an excellent option for creating custom apparel, home goods, and a variety of promotional products.

How does DTF printing differ from traditional methods like DTG and screen printing?

Unlike direct-to-garment (DTG) printing and traditional screen printing, DTF printing uses a unique transfer film and adhesive powder, allowing for more versatility and the ability to print on various fabrics, including non-cotton materials. This method is often more cost-effective and efficient for small runs.

What recent advancements have been made in DTF supplies?

Recent advancements in DTF supplies include improved ink formulations and DTF printers designed for better adhesion and washability. Major brands are releasing high-quality products that enhance the vibrancy and durability of printed designs, making DTF an exciting option for both businesses and hobbyists.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A printing technique that transfers high-resolution designs from a specially coated film to fabric with heat and pressure. |

| Recent Developments in DTF Supplies | Advancements have improved ink and film quality, enhancing adhesion, washability, and vibrancy of prints. |

| Essential DTF Supplies | Includes DTF printers, transfer films, adhesive powder, and heat presses for optimal results. |

| Pricing Trends in DTF Printing | Initial investment may be higher, but lower production costs can lead to long-term savings as market prices decline. |

| Applications and Design Capabilities | DTF printing is versatile, applicable on various materials for home goods and promotional products, supporting intricate designs. |

| Community and Education in DTF Printing | A supportive community exists online with forums, blogs, and channels dedicated to educating about DTF printing. |

Summary

DTF supplies have revolutionized the textile printing landscape, providing an innovative solution for creators and businesses alike. With Direct-to-Film printing, you gain access to durable and vibrant designs, making it a favored choice among fabric printers. The essential supplies such as specialized printers, transfer films, adhesive powder, and heat presses are crucial for a successful DTF printing experience. Moreover, as advancements in technology continue, the quality of materials and accessibility to equipment improve, resulting in a growing community of passionate users. Engaging with educational resources will enhance your understanding and skills in utilizing DTF supplies, ensuring you can create stunning fabric prints that stand out in the market.