The DTF Gangsheet Builder is revolutionizing the textile printing landscape by offering an optimized approach to Direct-to-Film (DTF) printing. This innovative tool allows users to consolidate multiple designs onto a single sheet, greatly enhancing efficiency and reducing waste. As businesses pivot away from traditional printing methods, the advantages of DTF printing become evident, particularly in terms of cost efficiency and print quality comparisons. With its capability to produce vibrant, intricate designs, the DTF Gangsheet Builder stands out among versatile printing techniques that cater to diverse fabric options. In this article, we will delve into how this cutting-edge tool compares against conventional methods, ultimately helping you choose the best printing solution for your needs.

The Direct-to-Film (DTF) Gangsheet Builder represents a significant technological advancement within the realm of fabric printing. Known for its unique ability to print multiple graphics on a single film, this technique is praised for its operational cost-saving benefits and superior print quality. As businesses explore dynamic alternatives to traditional methods like screen printing, understanding the advantages offered by DTF printing becomes critical. Enhanced versatility and the capacity for high-resolution designs make this approach appealing to both designers and manufacturers alike. This introduction sets the stage for a comprehensive analysis of how the DTF Gangsheet Builder stacks up against established printing practices.

Understanding DTF Printing and the Gangsheet Builder

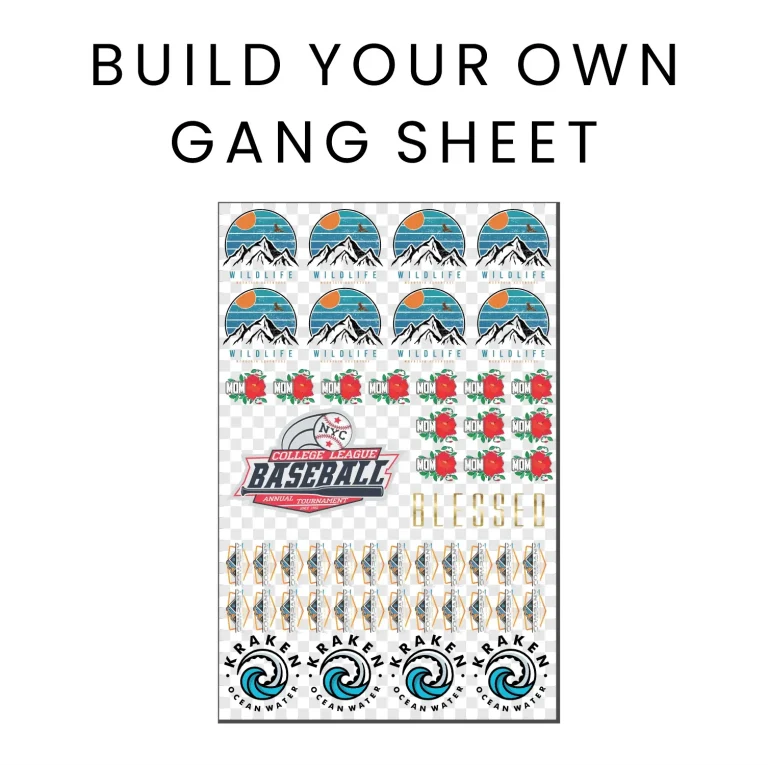

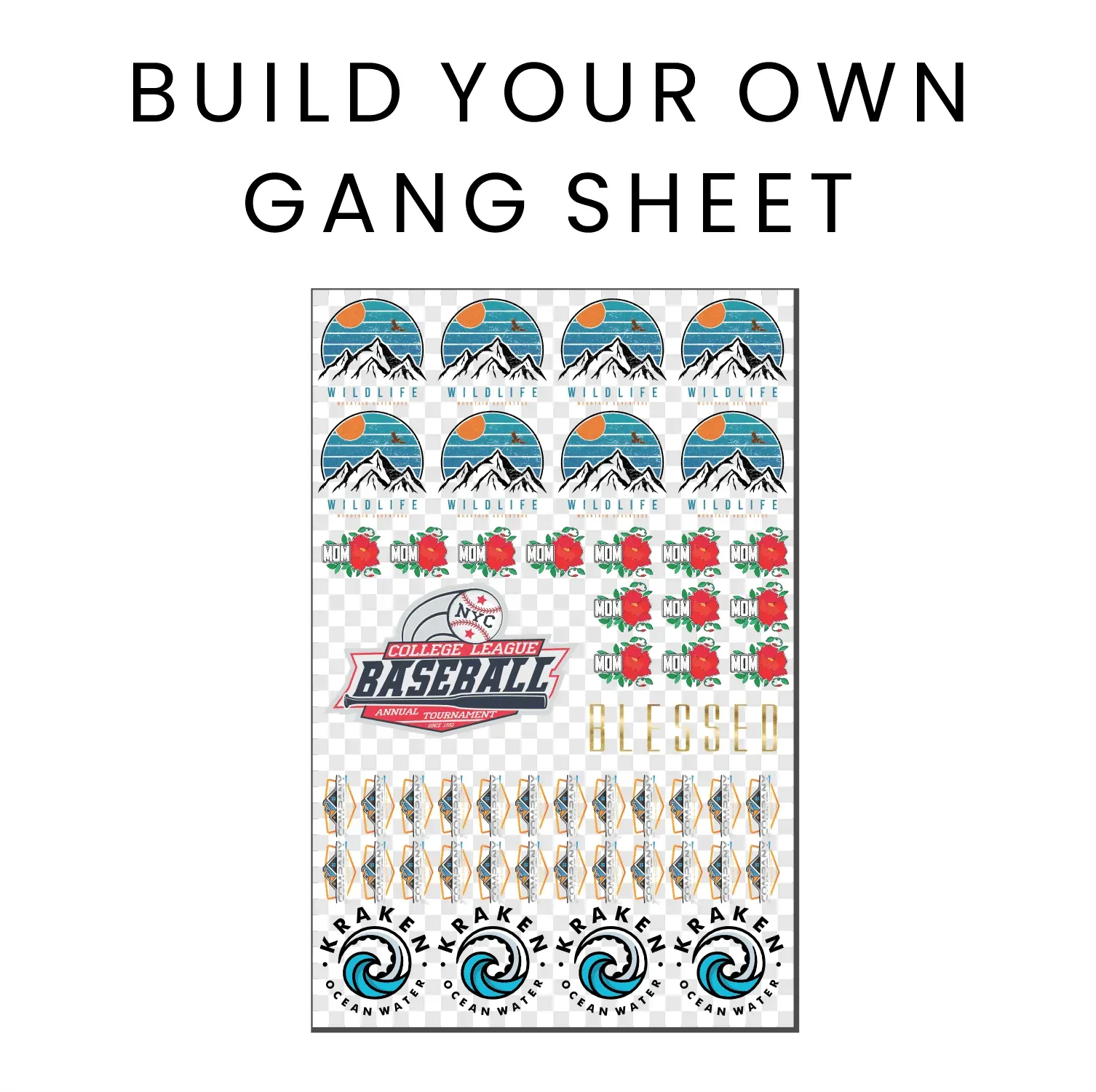

DTF printing, or Direct-to-Film printing, is increasingly being adopted in the textile industry due to its capacity for delivering remarkable print quality with vivid colors and intricate designs. The DTF Gangsheet Builder plays a crucial role in optimizing this process by allowing multiple designs to be printed on a single film sheet. This not only maximizes the material’s use but also minimizes waste, making it an excellent choice for environmentally conscious businesses looking to enhance sustainability while maintaining quality.

The benefits of using the DTF Gangsheet Builder extend beyond just efficiency; it also supports the production of personalized items in smaller runs, accommodating businesses that cater to unique customer demands. Unlike traditional methods that might require extensive setup for each design, the Gangsheet Builder streamlines this process, saving time and ensuring high-quality output on various fabrics.

Cost Efficiency of DTF vs. Traditional Printing

Cost is a significant factor influencing the choice of printing methods, and this is where DTF printing with the Gangsheet Builder shines. By utilizing a single sheet for multiple designs, businesses can significantly reduce their material costs. This process makes DTF printing exceptionally cost-effective, especially for small to medium-sized runs, as the overhead expenses are considerably lower than those associated with traditional screen printing, which often demands a larger upfront investment.

On the flip side, traditional printing methods like screen printing can be advantageous for larger orders due to economies of scale, yet they often incur higher costs for shorter runs. The initial setup and preparation for screen printing are also substantial, which can deter smaller businesses or startups. Therefore, the DTF printing method paired with the Gangsheet Builder stands out as a viable and economical option for those entering the market or those who regularly work with smaller batches.

Print Quality Comparisons Between DTF and Traditional Printing

When it comes to print quality, DTF printing has set a new standard that rivals traditional techniques. Advances in DTF technology have led to improved ink formulations that provide a broader color spectrum and enhanced detail, allowing for stunningly vivid prints that capture the minutest design intricacies. The use of the DTF Gangsheet Builder helps ensure that even complex designs maintain their clarity and color accuracy, regardless of the fabric used.

Traditional screen printing, while boasting long-lasting durability due to its heavier inks, may not always match the precision and vibrant output offered by DTF printing. Businesses seeking to deliver high-quality visuals without compromising on detail often find DTF printing to be their preferred choice, particularly for promotional apparel and intricate designs that need to stand out.

Versatile Printing Techniques: DTF vs. Traditional Methods

One of the significant advantages of DTF printing is its versatility. The DTF method can accommodate a wide range of fabrics—cotton, polyester, blends, and more—making it suitable for various products, from clothing to promotional items. The Gangsheet Builder enhances this versatility by allowing printers to efficiently layout and manage multiple designs on a single sheet, streamlining production and ensuring consistency across different apparel types.

In contrast, traditional screen printing primarily excels with cotton fabrics, which might limit its usability for businesses looking to expand their offerings to synthetic materials or mixed textiles. This limitation can hinder creativity and flexibility in meeting diverse customer demands, making DTF printing a more adaptable solution for modern textile businesses striving for variety.

Time Efficiency: DTF Printing with Gangsheet Builder

Time efficiency is critical in the fast-paced world of textile printing, and DTF printing has a clear advantage. The Gangsheet Builder significantly speeds up the production process by allowing several designs to be printed simultaneously on a single sheet. This feature not only saves time during the printing phase but also reduces the total turnaround time, making it easier to accommodate urgent orders and last-minute requests from clients.

In contrast, traditional printing methods typically involve longer setup periods, especially when switching between designs or colors. The additional time required for preparing screens and mixing inks can slow down production, leading to potential delays in delivery. By adopting DTF printing with the Gangsheet Builder, businesses can enhance their operational efficiency and improve customer satisfaction through timely fulfillment of orders.

Ease of Use in DTF vs. Traditional Printing

User experience is a vital component when selecting a printing method, and DTF printing excels in this area, particularly with the inclusion of the Gangsheet Builder. Although there may be an initial learning curve, the long-term benefits include a streamlined layout process that minimizes waste and simplifies the handling of multiple designs. This user-friendly approach is particularly appealing to businesses looking for efficient solutions that do not compromise on output quality.

On the other hand, traditional screen printing can be seen as more straightforward for established printing setups. However, it often requires significant manual input and labor, particularly for elaborate designs or custom orders. The time and effort involved in preparing screens can deter some operators, revealing a potential area where DTF printing can provide a more accessible alternative for new entrants to the market.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool used in Direct-to-Film (DTF) printing that optimizes the layout of multiple designs onto a single sheet of film. This maximizes film utilization, reduces waste, and enhances production efficiency, making it an essential feature for businesses looking to streamline their printing processes.

What are the advantages of DTF printing over traditional methods?

DTF printing offers several advantages over traditional printing methods, including cost efficiency, superior print quality, and versatility. The DTF Gangsheet Builder allows users to print multiple designs on a single sheet, significantly lowering material costs and minimizing waste, while producing vibrant prints suitable for various fabric types.

How does print quality from the DTF Gangsheet Builder compare to traditional printing methods?

Print quality from the DTF Gangsheet Builder is often superior due to its ability to achieve a wider color gamut and fine details. While traditional methods like screen printing provide durable results, advancements in DTF technology allow it to rival and often surpass the quality of traditional prints.

Is the DTF Gangsheet Builder cost-effective for small production runs?

Yes, the DTF Gangsheet Builder is particularly cost-effective for small to medium production runs. It minimizes film usage by allowing multiple designs to be printed on one sheet, leading to reduced material costs and waste compared to traditional printing methods that are usually more beneficial for larger batches.

What types of fabrics are compatible with DTF printing using the Gangsheet Builder?

DTF printing using the Gangsheet Builder is versatile and can be used on a variety of fabrics, including cotton, polyester, and blended materials. This adaptability makes DTF printing suitable for a wide range of applications, from clothing to promotional products, unlike traditional methods that are often limited to cotton.

Can the DTF Gangsheet Builder improve turnaround time for printing orders?

Absolutely. The DTF Gangsheet Builder enhances turnaround time by streamlining the printing process, allowing for faster production of multiple designs in one go. This efficiency is particularly beneficial for urgent orders, contrasting with traditional printing methods that typically require longer setup times.

| Key Point | DTF Gangsheet Builder | Traditional Printing |

|---|---|---|

| Cost Efficiency | Reduces film consumption by printing multiple designs, leading to lower costs. | Higher setup costs; advantageous for larger runs. |

| Print Quality | Offers a wider color gamut and high detail suitable for intricate designs. | Known for durability but traditionally focuses on fewer color details. |

| Versatility | Can print on various fabrics like cotton and polyester easily. | Primarily effective on cotton; limited with synthetic blends. |

| Turnaround Time | Faster production times due to streamlined processes. | Longer setup times for custom designs, which can delay delivery. |

| Ease of Use | Learning curve is steeper, but layout becomes manageable. | Generally user-friendly, but still requires considerable manual labor. |

Summary

DTF Gangsheet Builder represents a significant advancement in the realm of textile printing, offering advantages in cost efficiency, print quality, versatility, turnaround time, and ease of use when compared to traditional printing methods. This innovative tool is perfect for businesses that need to manage smaller production runs without sacrificing quality or incurring high material costs. As digital printing technologies continue to evolve, adopting the DTF Gangsheet Builder could prove to be a crucial step for businesses seeking to remain competitive in a rapidly changing market.