In the dynamic realm of textile printing, **DTF Printing**, or Direct-to-Film printing, stands out as a revolutionary technique that marries innovation with practicality. Unlike traditional methods, such as Direct-to-Garment (DTG) printing and screen printing, DTF offers remarkable versatility and exquisite detail for vibrant designs. This method has gained traction for its ability to produce high-resolution images while maintaining print durability, making it ideal for a variety of fabrics. As we delve deeper into the advantages of DTF transfers compared to other printing methods, the discussion will highlight the unique characteristics that position DTF as a game-changer in textile application. Whether you’re a manufacturer or a creative, understanding the nuances of DTF printing could be pivotal in redefining your approach to garment decoration.

Exploring alternatives in textile decoration often leads to an appreciation of **Direct-to-Film transfers** as an innovative solution. This technique offers an appealing mix of efficiency and quality that rivals established options like traditional screen and DTG printing. As we venture into this subject, it becomes evident that DTF, recognized for its vivid color output and robust applications, enhances the capabilities of modern trades in the textile printing landscape. This discussion on DTF will not only reveal its competitive edge over other methods, but also illustrate its adaptability across diverse materials and intricate designs, ultimately raising the bar for print quality in the industry.

Understanding DTF Transfers: The Future of Printing

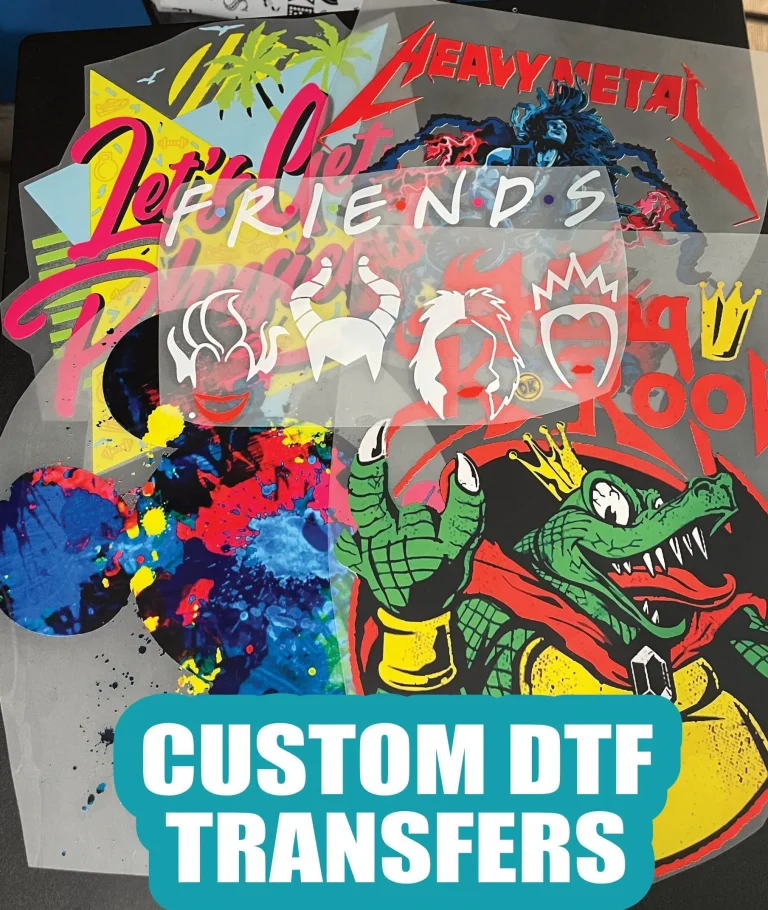

Direct-to-Film (DTF) transfers are rapidly gaining popularity in the textile printing industry due to their innovative approach to design application. Unlike traditional methods, DTF printing allows for the creation of intricate and vibrant graphics that are versatile enough to be applied to numerous fabric types. As a hybrid option, it marries the benefits of Direct-to-Garment (DTG) printing’s quality with the efficiency of screen printing. This combination not only streamlines the production process but also elevates the final product’s aesthetic appeal, rendering it a cutting-edge technique favored by many designers.

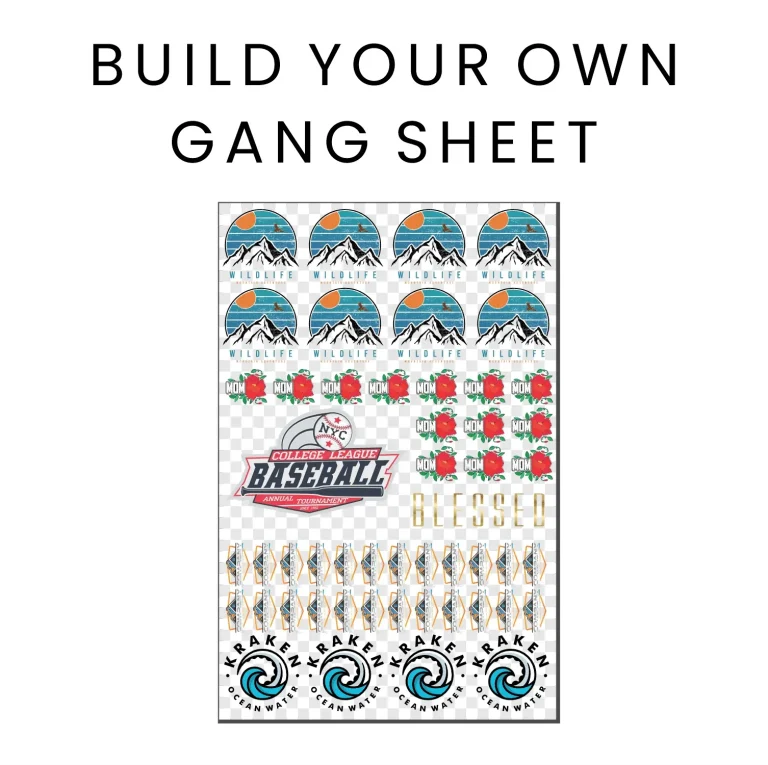

The DTF method employs a special kind of film that captures fine details and a broader spectrum of colors compared to other approaches. This capability makes DTF an outstanding choice for artists and businesses looking to create unique and visually striking pieces. DTF transfers are versatile, with applications on cotton, blends, and even synthetic fabrics, thus expanding the creative potential for various industries. As the demand for customized prints continues to grow, DTF printing stands out as an ideal solution, showcasing the potential for innovation within textile printing.

DTF Printing Versus DTG Printing: A Detailed Comparison

When setting DTF printing against Direct-to-Garment (DTG) printing, several key differences emerge that can influence a business’s choice of printing technology. DTG printing is renowned for its exceptional detail, making it perfect for high-resolution images directly on garments. However, its reliance on specific fabric types, primarily cotton, can limit its versatility. In contrast, DTF printing excels in its ability to apply designs on a wider range of materials, which provides businesses with more options for product offerings.

Moreover, efficiency is another major differentiator. DTF printing usually enjoys faster turnaround times due to its simplified setup process, which allows for quicker production of both small and large orders. While DTG printing involves longer preparation and maintenance efforts, DTF’s rapid production capabilities make it a more attractive option for businesses aiming to meet dynamic market demands without sacrificing quality.

Exploring the Benefits of DTF Transfers

The benefits of DTF transfers are numerous, making them a compelling choice for modern textile printing needs. One significant advantage is the ability to print in vibrant colors with high clarity, which is crucial for attracting customers in today’s visually driven market. Unlike screen printing, which can struggle with complex designs and gradients, DTF printing captures intricate details and delivers a colorful outcome that vividly represents an artist’s vision.

Additionally, DTF transfers boast impressive durability, which is essential for consumer satisfaction in the apparel industry. As customers increasingly seek long-lasting products, the wash durability of DTF prints becomes a critical selling point. Withstanding multiple washes without color fading or design peeling is a hallmark of this method, providing confidence to both manufacturers and consumers about the longevity of their investments.

DTF Printing’s Cost-Efficiency in Production

Cost-efficiency is a paramount consideration for any business involved in textile printing, and DTF printing offers notable advantages in this area. The relatively low setup costs associated with DTF technology allow for economic production, particularly for smaller batches or on-demand printing. In comparison, traditional screen printing often requires extensive preparation and equipment investment, making it less viable for brands looking to experiment with limited-edition runs or custom designs.

Furthermore, DTF printing minimizes waste and reduces production downtime, which can lead to exquisite cost savings over time. As businesses look to streamline their processes while maintaining high-quality output, the ability to produce vibrant designs quickly and at a lower cost serves as a significant draw for DTF technology. In an increasingly competitive market, employing cost-effective methods such as DTF can provide a substantial edge.

Comparative Analysis of DTF and Screen Printing

Screen printing remains a longstanding favorite in the textile printing industry, particularly for larger batch productions due to its economical per-unit cost. However, it exhibits limitations when compared to DTF printing, particularly regarding design complexity and color variation. DTF excels with intricate pieces, allowing finer detail and color gradients that screen printing may struggle to replicate effectively.

Moreover, as screen printing can often lead to longer lead times for setup, businesses that demand quick turnarounds may find DTF printing to be a superior alternative. DTF’s quicker adjustments and flexibility in production can meet pressing deadlines without compromising quality, a vital factor for many companies operating in fast-paced markets.

The Limitations and Challenges of DTF Printing

While DTF printing presents numerous advantages, it is not without its challenges. Initial equipment costs could be a barrier, particularly for new or small businesses trying to adopt this innovative technology. Potential adopters must weigh these costs against the benefits they anticipate gaining from utilizing DTF, as well as consider the ongoing expenses related to film and ink supplies.

Another challenge lies in the post-printing processes, which are crucial for preserving the integrity of the prints over time. Proper handling and adherence to recommended procedures are essential to ensure the print’s durability and quality. Businesses need to invest time in training staff and developing meticulous procedures to maintain the high standards that DTF printing promises, establishing a balance between risk and reward in adopting this method.

Frequently Asked Questions

What is DTF printing and how does it work?

**DTF printing**, or Direct-to-Film printing, involves printing designs onto a specialized film before transferring them onto textiles. This process allows for sharp, vibrant images that can adhere to various materials, including cotton and polyester. Unlike traditional **screen printing**, DTF offers higher resolution and is capable of producing intricate designs with impressive color fidelity.

How does DTF printing compare to DTG printing?

**DTF printing** and **Direct-to-Garment (DTG)** printing both aim for high-quality textile prints, but DTF stands out due to its versatility across different material types. While DTG is best suited for cotton fabrics, DTF can be used on a broader range of textiles, providing businesses with greater flexibility in their product offerings.

What are the advantages of DTF printing over screen printing?

**DTF printing** has several advantages over traditional **screen printing**. Primarily, it is more efficient for shorter production runs, as it requires less setup time. Additionally, DTF transfers can achieve vibrant colors and intricate details that are often challenging to replicate with screen printing, making it an attractive option for custom designs.

Is DTF printing cost-effective for small businesses?

While the initial investment in **DTF printing** equipment can be significant, the method’s efficiency and reduced setup costs make it cost-effective in the long run, especially for small businesses that require flexibility. DTF enables quick turnaround times, meaning businesses can capitalize on rapid order fulfillment without the financial burden of large batch productions typically associated with screen printing.

How durable are prints created using DTF printing?

Print durability is one of the key strengths of **DTF printing**. Studies indicate that DTF prints retain their quality through numerous washes, maintaining color vibrancy and design integrity over time. This durability makes DTF an excellent choice for apparel that is intended for long-term wear.

What materials can be printed using DTF technology?

**DTF printing** is highly versatile and can be applied to a variety of textiles, including cotton, polyester, and blended fabrics. This adaptability is a significant advantage over many other **textile printing methods**, allowing businesses to offer a wide range of products tailored to different consumer preferences.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A hybrid printing solution using special film to transfer designs onto textiles. |

| Key Advantages | Versatility, vibrant colors, efficiency, cost-effectiveness, and durability. |

| Comparison to Other Methods | DTG: High detail but slower for high volumes; Screen Printing: Cost-effective for large batches but less adaptable and fails at intricate designs. |

| Limitations of DTF | Initial equipment costs and need for proper post-printing processes to ensure design longevity. |

Summary

DTF Printing represents a remarkable evolution in the textile printing sector, blending efficiency and creativity in ways that set it apart from traditional methods. By utilizing a unique transfer process, DTF not only showcases vibrant colors and detailed designs but also caters to a wider range of materials, making it an appealing choice for both manufacturers and consumers. As the printing landscape continues to evolve, DTF printing is expected to play a pivotal role, allowing for innovative possibilities in garment design and production. Its balance of cost-efficiency and durability positions it as a favorable contender against well-established techniques like Direct-to-Garment and screen printing.