The DTF Gangsheet Builder is at the forefront of revolutionizing garment decoration, making it easier for professionals to streamline their workflows and improve print quality. As the demand for customized designs rises, understanding essential DTF printing tips becomes vital for achieving success in this competitive market. By optimizing DTF workflows through effective design layout strategies and quality control measures, businesses can reduce material waste and enhance overall productivity. Embracing these techniques allows for better management of ink and film compatibility, ensuring that every print meets high standards. Moreover, sustainable DTF printing practices not only reflect a commitment to environmental responsibility but also resonate with a growing customer base eager for eco-friendly options.

DTF printing, or Direct to Film printing, has emerged as a game-changer in the realm of fabric design and decoration. By utilizing advanced technology, the DTF Gangsheet Builder facilitates an efficient creation process, catering to the evolving needs of designers and print businesses alike. It’s crucial to grasp the fundamentals of this technique, as well as to implement online printing strategies that can enhance the effectiveness of design layouts and optimize workflow drastically. Maintaining consistent quality control during the DTF printing process ensures that the final products not only captivate customers but also stand the test of time. Furthermore, a growing focus on sustainable practices in DTF printing is shaping the industry, attracting those who appreciate innovation alongside ecological mindfulness.

Maximizing Efficiency with DTF Gangsheet Builder

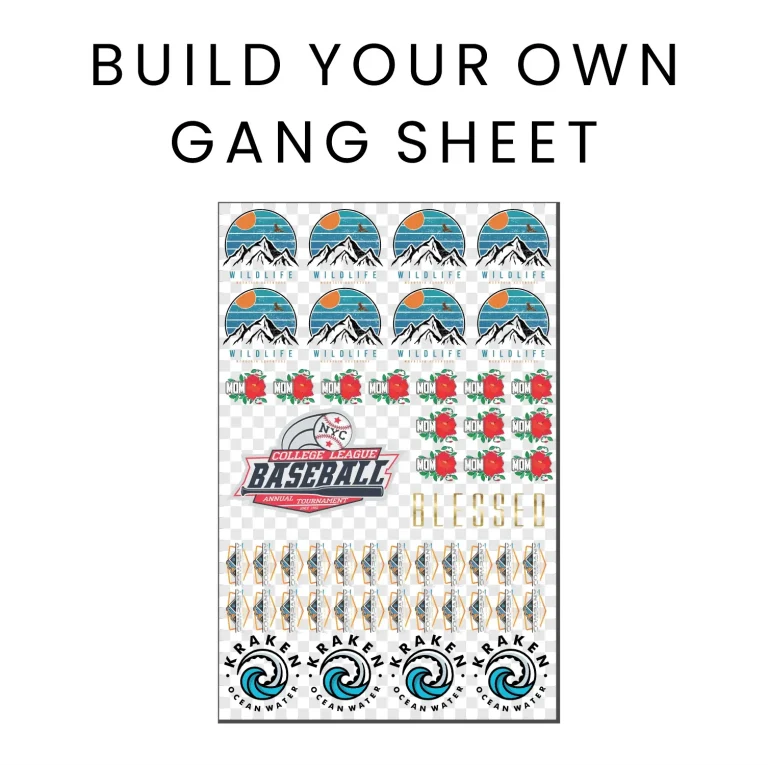

The DTF Gangsheet Builder is an essential tool for garment decorators looking to streamline their workflow while maximizing efficiency. This software allows users to arrange multiple designs on a single sheet, which not only saves on materials but also minimizes production time. By effectively utilizing the DTF Gangsheet Builder, you can strategically space and align your prints, ensuring that every inch of the sheet is used optimally. This level of precision not only enhances productivity but also contributes to higher-quality outputs, crucial in a competitive market.

Moreover, the DTF Gangsheet Builder simplifies the design process by providing users with intuitive layout options and templates. This means less time spent on arranging designs manually and more focus on perfecting the aesthetics of your prints. Coupled with features like color calibration and ink management, the DTF Gangsheet Builder becomes a comprehensive solution that enhances the overall workflow, allowing businesses to deliver high-quality products consistently.

Effective DTF Printing Tips for Beginners

For those new to DTF printing, understanding the right techniques and tips can make a significant difference in production success. One effective DTF printing tip is to familiarize yourself with the various types of inks and films available. Each type has unique properties that affect adhesion, flexibility, and durability. Experimenting with different combinations of inks and films can lead to discovering the perfect match for your specific fabric and design needs.

Additionally, incorporating a testing phase into your workflow is crucial. Regularly conducting test prints allows you to calibrate your printer settings for optimal results. Adjustments to pressure and temperature during the heat press process can have a pronounced impact on the final quality of your prints. By continuously refining your approach based on these tests, you will significantly enhance your understanding of DTF and improve your production quality over time.

Streamlining Your DTF Design Layout

A well-organized design layout is pivotal in DTF printing as it can lead to both material savings and improved efficiency. By strategically arranging multiple designs on a single gang sheet, printers can not only minimize waste but also enhance the overall aesthetic quality of the final product. Leveraging design software with nesting features can automate this process, allowing for optimal placement of designs on the sheet, thereby maximizing the use of ink and reducing excess waste.

Furthermore, consider the alignment of designs concerning the fabric grain and printing direction. Proper orientation ensures that designs adhere better and stand up to wear and tear. By taking these aspects into account during the DTF design layout stage, you can significantly increase the durability and appeal of your prints, leading to higher customer satisfaction and return business.

Quality Control in DTF Printing Workflows

Implementing a robust quality control process is an indispensable aspect of DTF printing. From the preparation stage to the final inspection, quality control ensures that each print meets industry standards and customer expectations. Establishing checkpoints throughout your workflow, where visual inspections and quality assessments are mandatory, can reduce the chances of defects that could lead to wasted materials and time.

Moreover, integrating feedback systems into your quality control process can create a culture of continuous improvement. This means actively seeking and utilizing insights from your team about potential flaws or inefficiencies. By fostering open communication and documentation of quality checks, businesses can often uncover patterns of issues and address them proactively, resulting in consistently high-quality outputs.

Sustainable Practices in DTF Printing

As the demand for environmentally-friendly alternatives increases, sustainable DTF printing practices are becoming more relevant in the industry. Using eco-friendly inks and recyclable films not only aligns with the growing consumer preference for sustainable products but also helps to reduce waste in your production process. By sourcing these materials, businesses can capture a niche market while contributing positively to the environment.

Additionally, adopting energy-efficient practices within your DTF printing workflow can significantly lower your operational costs. Investing in modern equipment that consumes less energy and produces minimal waste is not only beneficial for the planet but also enhances your brand’s reputation. Clients are more likely to support businesses that share their values regarding sustainability, making it a win-win situation for both parties.

Engaging with the DTF Printing Community for Growth

Engaging with the DTF printing community can provide invaluable resources and insights that can help optimize your DTF workflow. Online forums, social media groups, and websites dedicated to DTF printing often share tips, troubleshooting advice, and case studies from experienced professionals. By being an active participant in these spaces, you can keep up with the latest trends, challenges, and solutions in the industry.

Additionally, considering professional development through webinars and workshops specifically focused on DTF practices can greatly enhance your skill set. By continually learning and adapting to industry advancements, you set your business up for long-term success. Investing time in education not only broadens your knowledge but also empowers you to implement best practices that can elevate your DTF printing operations.

Frequently Asked Questions

What are the best DTF printing tips for optimizing a DTF Gangsheet Builder workflow?

To optimize your DTF Gangsheet Builder workflow, focus on utilizing specialized software for layout management, regularly check ink levels and film compatibility, and conduct routine test prints for calibration. Effective design layout optimization through nesting tools can also reduce waste and enhance efficiency.

How can I improve my DTF design layout for better print results?

Improving your DTF design layout involves careful arrangement of multiple images on a single gang sheet to maximize ink and film use. Utilize nesting features in your software to optimize design placements, thereby minimizing waste and improving overall print quality.

Why is quality control important in DTF printing?

Quality control in DTF printing is crucial to prevent wasted materials and costly errors. Implementing routine visual inspections and establishing checkpoints within your workflow ensures that defects are identified early, maintaining high standards in print output.

What should I know about sustainable DTF printing?

Sustainable DTF printing focuses on using eco-friendly inks and recyclable films, which not only helps the environment but also appeals to conscious consumers. As trends move towards sustainability, adopting these materials can enhance your brand’s reputation and sales.

How does automation impact the DTF Gangsheet Builder workflow?

Automation in the DTF Gangsheet Builder workflow can significantly reduce the time spent on manual setup and arrangement. Investing in automation tools streamlines processes, increases productivity, and allows for faster turnaround times, ultimately benefiting your overall DTF printing operations.

How can I leverage community resources for DTF printing optimization?

Engaging with the DTF printing community through online forums and educational resources like webinars can provide invaluable tips and best practices. Keeping abreast of industry trends and learning from professionals enhances your skills and helps in optimizing your DTF printing workflow.

| Key Aspect | Details |

|---|---|

| Introduction | Optimizing the DTF Gangsheet Builder workflow is essential for productivity, print quality, and waste reduction. |

| Understanding DTF Printing Basics | The process involves transferring designs onto garments using PET film, and material choices can impact quality. |

| Software Utilization | Using specialized software like Adobe Illustrator helps with layout management and color calibration. |

| Design Layout Optimization | Organizing images on gang sheets reduces waste; nesting tools can optimize arrangement. |

| Ink and Film Management | Regular ink level checks and compatibility with printer prevent issues and maintain quality. |

| Testing and Calibration | Routine test prints ensure color accuracy and adherence quality; adjust settings for optimal results. |

| Quality Control Implementation | Visual inspections and established checkpoints reduce errors and improve quality. |

| Education and Community Resources | Engaging with community resources and education keeps you updated on best practices. |

| Recent Trends Impacting DTF Workflows | Sustainability and automation trends are shaping efficient DTF printing operations. |

Summary

DTF Gangsheet Builder is pivotal for streamlining the garment decoration workflow. By understanding the essentials of DTF printing, utilizing specialized software for design, managing materials effectively, and implementing comprehensive quality control measures, businesses can significantly enhance their efficiency and output quality. Staying informed about recent trends such as sustainability and automation will further position you for success in the evolving landscape of DTF printing. Engage with the community and continuously seek educational resources to refine your skills and remain competitive.