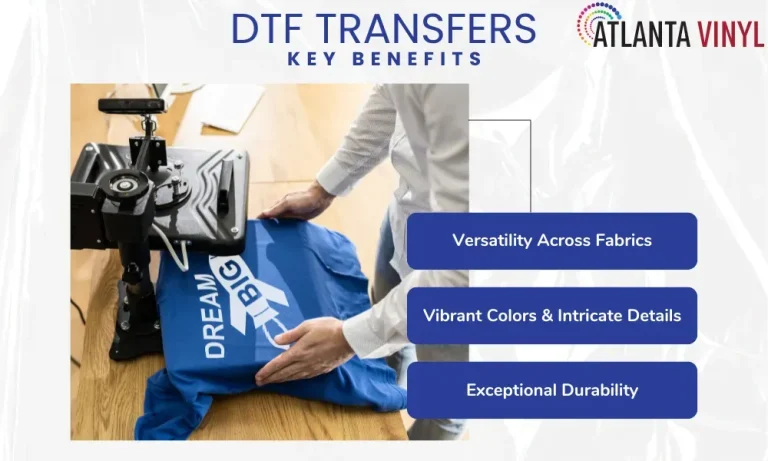

DTF transfers, or Direct to Film transfers, have transformed the t-shirt printing landscape, allowing for stunning, high-resolution designs that capture attention. Despite their advantages, many newcomers to this printing technique make common mistakes that can result in subpar outcomes. By familiarizing yourself with frequent pitfalls, such as incorrect artwork preparation or improper heat press settings, you can significantly enhance your printing success. This article delves into essential **DTF transfer guidelines** and **best DTF practices** that can help avoid **t-shirt printing errors**. Whether you’re an experienced printer or just starting out, these insights will equip you with **heat press tips** that ensure quality results with every transfer.

When exploring Direct to Film printing techniques, sometimes referred to as DTF printing or transfer printing, it’s crucial to address the common errors that can hinder the quality of the final product. These methods enable printers to achieve remarkable color vibrancy and detail, yet several missteps can detract from the efficacy of the process. From inadequate pre-treatment of garments to neglecting post-press care, understanding these challenges is fundamental for success. This discussion will illuminate the best practices necessary for achieving flawless results, highlighting essential tips and guidelines for effective use of this innovative printing approach. By mastering these techniques and avoiding miscalculations, printers can ensure that their creations not only look great but also last.

Understanding DTF Transfer Guidelines for Optimal Results

When using DTF transfers, adhering to the proper guidelines is essential to produce high-quality prints. The DTF printing process begins with choosing the right materials, including the film and adhesive powder, both of which are critical for ensuring that the images transfer accurately onto the garments. Furthermore, understanding the specifications of your heat press machine is also necessary to maximize the effectiveness of the transfer. This means knowing the temperature settings, the pressure required, and the duration of pressing, which can all significantly affect the final product.

In addition to the technical aspects, it’s also important to follow specific artwork guidelines. Make sure that your designs are vectorized and properly sized to fit the garments for which they are intended. This attention to detail goes a long way; mistakes in alignment can lead to wasted materials and unsatisfactory outcomes. Avoiding these common pitfalls will help streamline the printing process and ensure that your DTF transfers yield vibrant and lasting results.

Best DTF Practices: Steps to Achieve Impressive Prints

To achieve impressive prints using DTF transfers, implementing best practices from the beginning of the process is key. Start with high-resolution artwork that is compatible with DTF printing. The clearer your image, the better your final product will be. For best results, use CMYK color profiles, which align better with most printers’ outputs, ensuring that colors appear as intended on the final product. Moreover, always perform a dry-run on sample fabric to check color accuracy and overall quality before proceeding with bulk production.

Another important practice is to regularly clean your heat press and printing equipment. Build-up of residue can lead to inconsistent results and even damage your materials. Additionally, consider calibrating your printer settings occasionally to adapt to variations in materials or inks you may be using. By establishing a thorough practice regime and maintaining your equipment, you can greatly enhance the quality of your DTF transfers.

Common T-Shirt Printing Errors to Avoid Using DTF

While DTF transfers offer a myriad of opportunities in t-shirt printing, several common errors frequently occur. One prevalent mistake is the incorrect temperature and pressure settings applied during the heat press phase. Each type of film and ink combination may require different parameters, and failing to adjust these properly can lead to incomplete adhesion or image distortion. Testing these settings during initial trials can save time and materials, ultimately preventing costly errors during high-demand production runs.

Another frequent error is neglecting the pre-treatment of garments. Failing to pre-treat t-shirts can lead to peeling or cracking after multiple washes, causing dissatisfaction among customers. It’s essential to establish a consistent pre-treatment process to enhance the bond between the garment and the transfer, thus ensuring a longer-lasting finish. Avoid these pitfalls through careful planning and execution of each step in the DTF transfer process.

Heat Press Tips for Successful DTF Transfers

Successful DTF transfers rely heavily on effective heat press techniques. Understanding your heat press machine’s calibration, including its temperature readouts and pressure levels, is fundamental. Ensure your machine is preheated to the correct temperature before beginning, as this will ensure the adhesive activates properly during the transfer. It can also be helpful to invest in a heat press with digital temperature controls, which provide better precision than manual settings.

In addition to temperature, the pressure applied during pressing should be consistent and adequately adjusted according to the thickness of the substrate. During transfer, apply even pressure across the entire image area for optimal results and to avoid areas where the transfer might lift or bubble. Using a Teflon sheet can also provide an extra layer of protection against scorching, ensuring a smooth and successful transfer every time.

Avoiding Overuse of Adhesive Powder in DTF Printing

The application of adhesive powder in DTF printing is a critical step that necessitates precision. Overuse or underuse can lead to uneven transfers or failure, and achieving the right balance is essential for high-quality results. Always consult the manufacturer’s guidelines regarding the recommended amount to use based on the design’s size and complexity to avoid errors. Keeping a consistent application technique and using tools like measuring spoons can help maintain the right quantities.

Moreover, consider practicing your application technique on scrap material before moving on to your primary print jobs. This practice will help you understand how much adhesive is required for different fabrics and designs. Avoiding common mistakes in adhesive application leads to better adhesion and ultimately prolongs the life of your prints, making it a vital aspect of DTF printing.

Regular Maintenance: Enhancing Quality in DTF Printing

Regular maintenance of your printing equipment is often overlooked, but it plays a crucial role in the quality of DTF prints. Keeping your heat press in top condition, ensuring that heat plates are clean and free of debris, and checking pressure settings can prevent many problems that arise during the printing process. Additionally, routine checks and cleaning of inkjet printers help prevent clogs or blockages that can lead to poor ink distribution.

Moreover, keeping your DTF printing software updated is essential. Software updates can enhance compatibility with new types of materials and provide upgrades that improve overall printing performance. Regular maintenance ensures that your entire printing setup runs smoothly, minimizes downtime, and contributes to producing quality t-shirts that satisfy your customers.

Frequently Asked Questions

What are common mistakes to avoid when using DTF transfers for t-shirt printing?

Common mistakes in DTF transfers include neglecting proper artwork preparation, using the wrong film, and incorrect temperature and pressure settings. These can lead to dull prints, poor adhesion, and fabric damage. Always prepare high-resolution files, choose the right transfer film, and conduct test prints to determine optimal heat press settings.

How can I properly prepare my artwork for DTF transfers?

To properly prepare your artwork for DTF transfers, ensure you use high-resolution images in PNG or TIFF formats. Check that your graphics are set in the CMYK color mode and are correctly sized for the garment. This preparation is crucial to achieving vibrant colors and clear images after the transfer.

What is the importance of using the right film for DTF transfers?

Using the right DTF transfer film is essential because it impacts adhesion and image quality. Films specifically designed for DTF printing enhance ink adherence, making the prints clearer and more vibrant. Experiment with different films to find the one that works best for your specific printing needs.

What temperature and pressure settings should I use for DTF transfers?

Temperature and pressure settings can vary based on your specific DTF printer and transfer film. It is best to conduct test prints to determine the optimal settings that yield superior results. Improper settings can lead to incomplete adhesion or damage to the fabric.

Why is pre-treatment of garments necessary for DTF transfers?

Pre-treatment of garments is crucial because it creates a better surface for the DTF transfer to adhere. This step significantly enhances the durability and washability of the printed design, preventing issues like peeling or cracking after a few washes.

What should I remember about post-press curing with DTF transfers?

Post-press curing is important for the durability of DTF prints. After the transfer, allow the shirt to cool and cure for the recommended time to avoid cracking or peeling of the design. Properly curing the transfer increases its lifespan, leading to greater customer satisfaction.

| Key Point | Description |

|---|---|

| Neglecting Proper Preparation of Artwork | Ensure high-resolution images in PNG or TIFF formats and use CMYK color mode to avoid dull prints and ensure clarity. |

| Not Using the Right Film | Choose films specifically designed for DTF printing to achieve better adhesion and image quality. |

| Incorrect Temperature and Pressure Settings | Test different heat press settings to find optimal temperature and pressure for your specific materials to avoid poor adhesion. |

| Inadequate Pre-Treatment of Garments | Pre-treating garments enhances adhesion and durability of transfers, preventing peeling after washes. |

| Ignoring Post-Press Curing | Allow the transfer to cure properly after pressing to ensure longevity and prevent defects in the print. |

| Overusing or Misapplying Adhesive Powder | Follow manufacturer instructions for adhesive application to ensure even coating and effective transfers. |

| Lack of Server Maintenance and Updates | Keep software updated and perform maintenance to prevent printing quality issues and workflow interruptions. |

Summary

DTF transfers have become a game changer in t-shirt printing by allowing vibrant colors and intricate designs, but many users face common pitfalls that hinder their success. By recognizing these mistakes—from neglecting proper artwork preparation to failing to pre-treat garments—printers can significantly enhance the quality of their finished products. Proper preparation, appropriate materials, and diligent post-press care are essential for creating stunning prints that customers will love. With attention to detail and best practices, anyone can master the DTF transfer process and offer high-quality printed t-shirts.