DTF transfers, or Direct to Film transfers, have emerged as a game-changer in the realm of custom apparel, providing a stunning solution for those seeking high-quality prints. This innovative printing technique offers exceptional vibrancy and unparalleled detail, making it a top choice for personalized clothing. With the rising trend of customized fashion, the demand for effective and cost-effective printing solutions continues to grow. DTF printing not only enhances creativity but also promotes sustainable printing options, appealing to modern consumers who value eco-friendly practices. In this article, we will delve into the overall benefits of DTF transfers and their impact on the world of custom apparel.

When discussing innovative apparel printing methods, DTF printing often comes up as a leading choice due to its efficiency and quality. This technology allows designs to be printed on film and then transferred onto various fabrics, ensuring sharpness and vibrancy that stand the test of time. By stepping away from traditional printing methods, businesses and creators alike can explore a variety of sustainable printing techniques that meet contemporary demands for customization. With features such as adaptability to different fabrics and cost-effectiveness for smaller orders, it’s no wonder that DTF transfers are becoming synonymous with the future of personalized clothing.

Understanding DTF Printing Technology

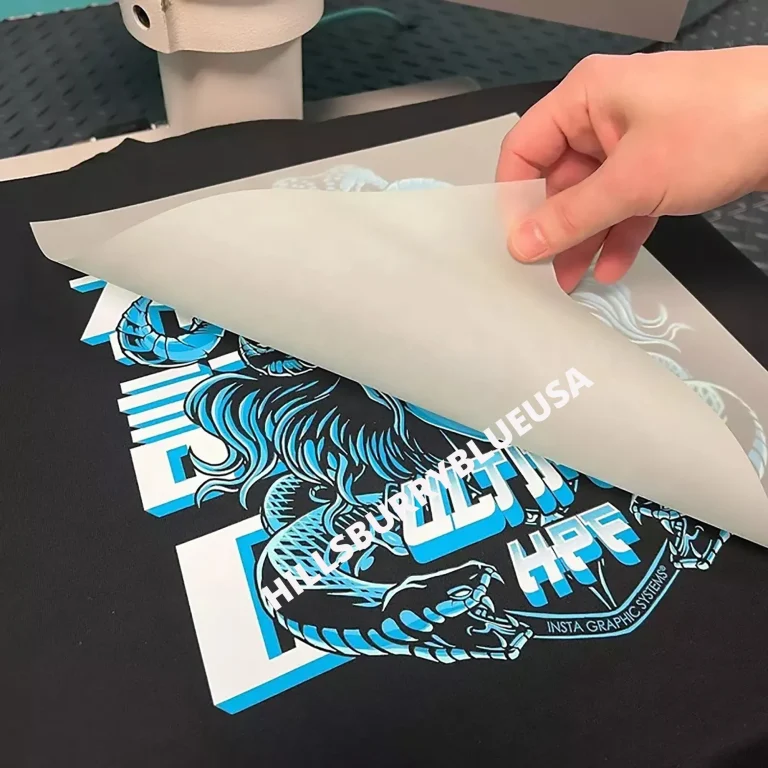

Direct to Film (DTF) printing represents a significant advancement in the custom apparel industry, merging cutting-edge technology with practical applications. This innovative process involves printing designs onto a special film, followed by heat pressing that film onto fabric. The result is not only vivid and photorealistic imagery but also a reliable technique that works on a variety of materials. With its inception reforming traditional printing methods, DTF technology caters to the growing demand for high-quality prints that can stand up to the test of time.

Furthermore, DTF printing proves to be a vital asset for businesses looking to expedite production times while minimizing costs. Compared to traditional printing methods, which often require complex setups and lengthy processes, DTF offers a simpler approach. This involves less equipment investment and fewer skilled labor requirements, streamlining operations and enabling even small businesses or startups to thrive in the competitive landscape of custom apparel.

Frequently Asked Questions

What are the benefits of using DTF transfers for custom apparel?

DTF transfers are gaining popularity due to their high-quality prints, versatility across various fabrics, durability, and cost-effectiveness for small runs. This printing method allows for intricate designs, ensuring vibrant colors and details that resonate with the essence of custom apparel.

How does DTF printing compare to traditional methods in terms of cost?

DTF printing is more cost-effective for small runs compared to traditional screen printing, which often requires minimum order quantities. This flexibility allows small businesses and individual creators to experiment with new designs without incurring high expenses.

Can DTF transfers be used on different types of fabrics?

Yes, DTF transfers are versatile and can be applied to a variety of fabrics, including cotton, polyester, and blends. This adaptability enables designers to explore different styles and textures without worrying about printing method limitations.

How long do DTF prints last on custom apparel?

DTF prints are known for their durability, resisting fading, cracking, and peeling even after multiple washes. This longevity makes them an ideal choice for custom apparel that is worn frequently, ensuring customer satisfaction over time.

Is DTF printing a sustainable option for custom apparel?

Many DTF inks are water-based and free from hazardous solvents, making them a more environmentally friendly choice in the printing industry. This approach not only appeals to eco-conscious consumers but also aligns with sustainable business practices.

What makes DTF transfers easy to apply for custom printing?

DTF transfers are easy to apply through a heat press, which simplifies the application process compared to other methods like screen printing or sublimation. This ease of use makes DTF printing accessible for beginners looking to enter the custom apparel market.

| Key Benefit | Description |

|---|---|

| High-Quality Prints | Produces vibrant colors and sharp details, ensuring customer satisfaction. |

| Cost-Effective for Small Runs | Allows for low volume orders without excessive costs, supporting artistic experimentation. |

| Versatility on Various Fabrics | Applicable on a variety of fabrics, enhancing design options for creators. |

| Durability | Long-lasting prints resistant to fading, cracking, and peeling after washes. |

| Ease of Application | Simple heat press application makes it accessible for beginners and scalable for businesses. |

| Reduced Environmental Impact | Water-based inks and fewer hazardous solvents align with sustainable practices. |

Summary

DTF transfers represent a transformative approach to custom apparel printing, merging quality and efficiency. As we delve into personalization in fashion, DTF transfers stand out for their vibrant color reproduction and adaptability to various fabrics. Their cost-effectiveness makes them accessible for small-scale orders, while the durability ensures that designs remain intact despite frequent washing. Moreover, the ease of application opens the doors for novice designers, enhancing its appeal in the competitive custom apparel market. DTF technology not only meets the aesthetic demands of consumers but also aligns with sustainable practices that are increasingly valued today. As the printing technology evolves, DTF transfers are poised to secure their role in redefining how we approach custom clothing.