DTF Supplies are an essential foundation for anyone looking to delve into the innovative world of Direct to Film (DTF) printing. This printing technique has revolutionized custom apparel printing, allowing users to reproduce complex designs and vibrant colors on a variety of fabrics. To achieve high-quality results, having the right tools, including a DTF printer, heat transfer film, and adhesive powder, is vital. With the growing popularity of DTF printing, understanding the core supplies is the first step toward mastering this front-running method in fabric decoration. In this article, we will explore everything you need to know to set up your DTF printing operation and create stunning apparel that captivates your audience.

When exploring the realm of DTF printing, it’s important to recognize this technique under its alternative terms such as Direct-to-Film printing or fabric transfer printing. These expressions encapsulate the process of applying intricate designs onto textiles through a specialized substrate, known as transfer film, coupled with heat. The pivotal equipment involved includes dedicated printers tailored for this purpose, along with essential materials like powdered adhesives needed to ensure a permanent bond of the design during the application. As more creators and businesses seek to make their mark with personalized designs, understanding this innovative approach becomes crucial for success in the competitive custom apparel landscape. In the following sections, we will provide you with a comprehensive overview and the resources necessary to navigate your DTF printing journey.

Understanding DTF Printing Technology

DTF printing technology represents a breakthrough in the garment decoration industry. Unlike traditional methods like screen printing or DTG (Direct to Garment), DTF printing utilizes a specialized film through which ink is transferred directly to the fabric. This quick and efficient process allows for vibrant color reproduction and intricate designs that were previously difficult to achieve. With advances in DTF printers and inks, more creators are discovering the potential for custom apparel solutions that meet modern consumer demands.

The appeal of DTF printing lies in its versatility, accommodating a diverse range of fabrics from cotton to polyester and everything in between. Users can experiment with different materials, creating custom apparel that caters to various market segments. As DTF technology continues to evolve, so does the quality of prints, ensuring that the designs remain vivid and durable even after multiple washes. This makes it a favorable choice for both independent designers and small businesses looking to expand their product offerings.

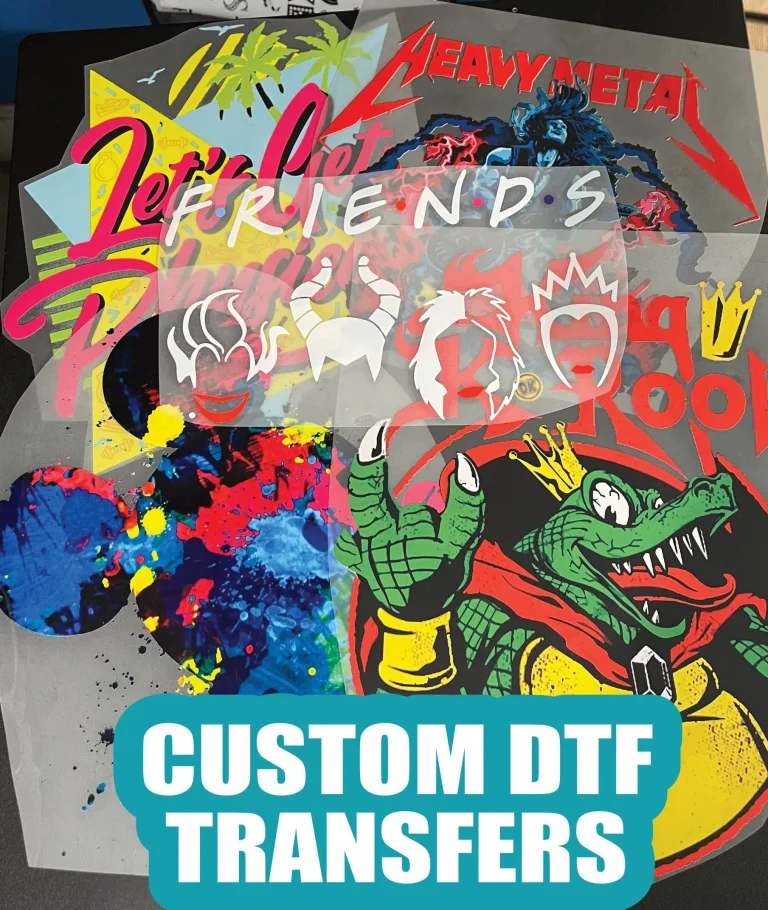

Essential DTF Supplies for Successful Printing

To embark on your DTF printing journey, you’ll need several essential supplies that will ensure optimal results. At the core of your setup is a reliable DTF printer specifically designed for this printing method. High-quality printers such as those from major brands like Epson and Roland are popular choices among professionals. These printers support high-resolution outputs and are designed to handle the unique demands of DTF printing, ensuring your designs translate perfectly onto garments.

In addition to the printer, heat transfer film is crucial for success in DTF printing. The right type of PET film allows the vibrant colors of your designs to shine through, providing the necessary compatibility for subsequent heat application. Don’t overlook the significance of adhesive powder, which acts as a bonding agent between the ink and the fabric, ensuring that your designs don’t fade or peel. By investing in high-quality supplies, you’ll build a foundation for creating stunning custom apparel.

Step-by-Step DTF Printing Process

The DTF printing process involves several clear steps that anyone can follow to achieve professional-quality results. Begin by calibrating your DTF printer to ensure the perfect balance of ink density and color settings. This is pivotal as it will directly affect the final output of your designs on the transfer film. Once your design is printed, carefully manage the application of adhesive powder. This step requires precision; too much or too little can lead to unsatisfactory outcomes.

Next, the curing process is essential for securing the adhesive to the design. Using a heat press at the right temperature and pressure, carefully cure the film to ensure the adhesive properly bonds. Afterward, the actual transfer to fabric begins. Place the prepared film onto your garment and apply the heat press, following the recommended settings. Finally, peel away the transfer film to reveal your completed design — a process rewarding for its simplicity and effectiveness.

Trends in DTF Printing

As we navigate the DTF printing landscape, several trends have emerged that are shaping the industry. One notable trend is its cost-effectiveness, especially for small businesses aiming to minimize overhead. By using DTF printing, entrepreneurs can produce customized merchandise quickly and affordably, opening up new avenues for creativity and innovation in their products. This has led to an influx of small brands that can compete effectively in the market.

Another significant trend is the focus on eco-friendly practices. As consumer preferences shift towards sustainable options, using water-based inks in DTF printing aligns perfectly with this demand. This not only benefits the environment but also enhances brand loyalty among conscious consumers. Customization continues to be at the forefront of DTF printing, with increasing customer desires for personalized designs that reflect their individual styles and preferences.

Learning Resources for DTF Printing Beginners

For newcomers to DTF printing, access to quality learning resources is invaluable. Platforms such as YouTube offer a plethora of video tutorials ranging from basic setup to advanced troubleshooting techniques. These visual aids can be particularly helpful in understanding both the intricacies of DTF technology and practical tips that enhance your printing experience.

Moreover, engaging in community forums provides a rich source of support where you can share experiences with others in the DTF printing field. These forums are filled with seasoned practitioners willing to share their knowledge and assist you in solving common issues. Exploring comprehensive websites dedicated to DTF printing will also equip you with necessary insights, supply recommendations, and artistic inspiration for your custom apparel projects.

The Future of DTF Printing

Looking ahead, the future of DTF printing appears bright, with ongoing advancements in technology likely to push its capabilities even further. Innovations in printer technology and software will simplify the printing process and enable even more detailed designs, meeting the evolving needs of consumers and brands alike. Additionally, as more industries discover the benefits of DTF printing, we can expect an expansion in its applications, paving the way for niche markets and specialized products.

For businesses, this may mean an increased focus on creativity and customization as unique prints become essential to capturing consumer interest. The growing popularity of DTF printing suggests that it will continue to make waves in the custom apparel industry, making it indispensable for both novices and seasoned professionals. With the right DTF supplies and knowledge, your ability to innovate within this market is endless.

Frequently Asked Questions

What supplies do I need for DTF printing?

To start with DTF printing, you will need a reliable DTF printer, high-quality heat transfer film, adhesive powder, compatible water-based inks, a heat press machine, and graphic design software to create your designs.

How does adhesive powder work in DTF printing?

Adhesive powder plays a crucial role in DTF printing by bonding the ink to the transfer film. After printing your design on DTF film, you sprinkle the adhesive powder over the wet ink, and once cured, it ensures a strong bond when transferring to fabric.

Can I use any printer for DTF printing?

No, not all printers are suitable for DTF printing. You need a specialized DTF printer, such as certain models from Epson or Roland, which are designed to handle the unique requirements of DTF printing and produce high-quality, vibrant prints.

What is heat transfer film and its importance in DTF supplies?

Heat transfer film, specifically PET transfer film, is essential for DTF printing as it is where your design is first printed before being transferred to garments. The quality of the heat transfer film can significantly impact the final print quality.

Is DTF printing eco-friendly?

Yes, DTF printing can be considered eco-friendly, especially when using water-based inks. This method generally has a lower environmental impact compared to traditional printing methods that use solvent-based inks.

What trends are emerging in the DTF printing industry?

Current trends in DTF printing include a growing emphasis on customization in apparel, the rise of eco-friendly practices among consumers, and its cost-effectiveness for small businesses, allowing them to produce high-quality custom merchandise.

| Key Point | Details |

|---|---|

| What is DTF Printing? | A printing method where designs are printed onto a special film for transfer to garments, producing high-quality, vibrant prints. |

| Essential Supplies | 1. DTF Printer – Essential for quality prints. 2. Heat Transfer Film – PET film for optimal results. 3. Adhesive Powder – Bonds the ink to the fabric. 4. Inks – Eco-friendly water-based inks. 5. Heat Press Machine – Transfers designs to garments. 6. Software – Design tools like Adobe Illustrator or DTF-specific software. |

| DTF Printing Process | 1. Print your design on DTF film. 2. Sprinkle adhesive powder on the wet ink. 3. Cure the adhesive with a heat press. 4. Transfer the design to garments. 5. Peel away the film for your finished product. |

| Current Trends | – Cost-effective for small businesses. – Eco-friendly with water-based inks. – Focus on custom and personalized designs. |

| Learning Resources | – Online tutorials on platforms like YouTube. – Community forums for advice. – Websites with detailed information on DTF. |

Summary

DTF Supplies are essential for anyone looking to explore the exciting world of Direct to Film printing. As a popular choice in garment decoration, DTF printing combines versatility with vibrancy, allowing for high-resolution prints that cater to diverse fabric types. By securing the necessary DTF Supplies—ranging from specialized printers and heat transfer films to high-quality inks and heat presses—users can create stunning custom apparel with relative ease. Understanding the workflow and current trends further enhances their ability to stand out in a competitive market. With the right tools and knowledge, embarking on a DTF printing journey can lead to remarkable results and business success.