In recent years, the printing industry has seen transformative advancements, and one standout innovation is **UV DTF Gangheet** (Direct to Film) printing. This cutting-edge custom printing technology enables high-definition imagery on a plethora of surfaces, providing an unparalleled level of detail and vibrancy. UV DTF Gangheet is not just about aesthetics; it boasts durability and versatility, making it an ideal choice for a range of applications—from fashion to promotional items. Moreover, with an increasing emphasis on eco-friendly printing solutions, this method addresses sustainability concerns while delivering exceptional results. Join us as we explore the remarkable benefits and future potential of UV DTF printing in the evolving landscape of creative production.

The emergence of **UV DTF Gangheet technology** has revolutionized the way we think about modern printing processes. Often referred to as Direct to Film printing, this method offers a unique blend of adaptability and precision, making it suitable for a wide array of substrates. As businesses increasingly seek versatile printing methods that can cater to diverse needs, UV DTF stands out with its ability to produce stunning graphics and long-lasting quality. This alternative, innovative printing approach not only emphasizes durability but also aligns with current trends favoring eco-friendly solutions. In this article, we will dive deeper into the nuances of this technology and its significance in today’s market.

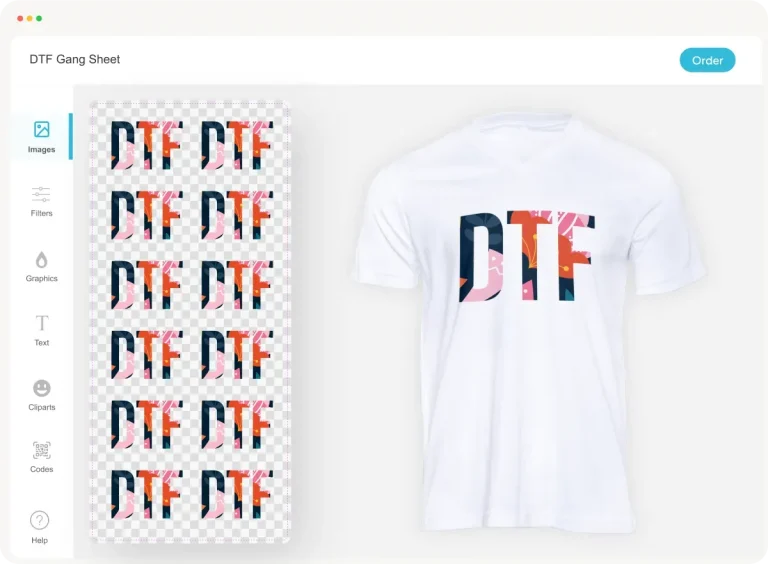

Exploring the Versatility of UV DTF Printing

UV DTF printing is heralded for its remarkable versatility in the world of custom printing technology. This technique allows for the application of designs on an array of materials, including textiles, ceramics, wood, and metals, making it invaluable for diverse industries. Businesses can leverage this capability to create anything from high-quality fashion items to durable promotional gifts, all while maintaining vibrant colors and fine details that enhance their brand’s visibility.

Moreover, the adaptability of UV DTF Gangheet printing means that companies can easily switch between different substrates without the need for extensive setup changes. This efficiency not only saves time but also reduces operational costs, allowing for more seamless production processes. As a result, whether it’s a small batch of personalized gifts or large-scale production runs, UV DTF printing consistently delivers exceptional results.

Durability: A Key Advantage of UV DTF Gangheet Technology

One of the primary selling points of UV DTF Gangheet technology is its unmatched durability when compared to traditional printing methods. The UV-curable inks used in this process create a hard surface that resists scratching, fading, and environmental wear. This characteristic makes UV DTF prints ideal for high-traffic items such as promotional products and sports apparel, ensuring that your prints maintain their quality over time.

In addition to physical resilience, UV DTF printing also provides excellent color stability, meaning that colors remain vibrant for years, even when subjected to outdoor conditions. For businesses aiming for long-lasting branding solutions, the durability of UV DTF prints ensures that every design stands the test of time, maintaining brand identity in a visually impactful manner.

Eco-Friendly Printing Solutions with UV DTF Gangheet

As more companies embrace sustainability, UV DTF printing is emerging as a frontrunner in eco-friendly printing solutions. The process emits significantly lower levels of volatile organic compounds (VOCs) compared to solvent-based ink processes, aligning with global efforts to reduce environmental impact. By opting for UV DTF technology, businesses not only gain high-quality prints but also contribute to greener practices in their operations.

Furthermore, the absence of harmful solvents in the UV DTF printing process allows businesses to market themselves as environmentally conscious, appealing to the growing demographic of eco-minded consumers. With rising awareness and demand for sustainability, incorporating UV DTF printing into your workflow not only positions your brand as a responsible choice but also opens up new market opportunities.

Recent Developments in UV DTF Gangheet Technology

The landscape of UV DTF printing is rapidly evolving, with ongoing advancements that continually enhance its application and efficiency. Recent technological innovations have improved both the speed and quality of prints, allowing businesses to fulfill orders much faster without compromising on detail or vibrancy. As manufacturers invest in research and development, these improvements position UV DTF technology as a strong competitor against established printing methods like Direct to Garment (DTG) and screen printing.

In addition, software advancements and improved ink formulations have made it easier for operators to achieve precise results consistently. This not only increases productivity but also ensures that even complex designs can be replicated reliably across different materials, reinforcing the appeal of UV DTF Gangheet in the modern printing marketplace.

The Diverse Application Areas for UV DTF Gangheet Printing

UV DTF Gangheet technology boasts an extensive range of applications, making it a versatile choice for various sectors. One notable area is the production of unique promotional items, where businesses can create customized products that capture attention and generate interest. From vibrant drinkware to tailored apparel, the capabilities of UV DTF printing help brands craft standout items that foster consumer engagement.

Another significant application lies within sports apparel, where brands are seeking to elevate team uniforms and merchandise. The ability to print intricate designs on flexible fabrics ensures that gear not only looks distinctive but also withstands rigorous activity and washing processes. As a result, sportswear manufacturers are increasingly turning to UV DTF printing to create high-quality, visually appealing products that meet athlete’s demands.

Future Prospects of the UV DTF Printing Industry

As we gaze into the future of the printing industry, the prospects for UV DTF technology appear bright. Market analysts predict significant growth as companies recognize the efficiency and quality that UV DTF printing brings to the table. Additionally, as costs associated with the technology decrease, its adoption is likely to accelerate across various industries, leading to more businesses integrating this advanced printing method into their operations.

Moreover, the adaptability of UV DTF printing positions it well to cater to emerging market trends, such as customization and on-demand production. As consumers continue to seek personalized products, the ability to offer unique designs quickly and affordably through UV DTF Gangheet will be a critical factor in maintaining competitive advantage among printing service providers. This trend could potentially reshape the landscape of custom printing, making UV DTF an indispensable player.

Frequently Asked Questions

What is UV DTF Gangheet and how does it work?

UV DTF Gangheet, or Direct to Film printing, is an advanced printing technique that uses UV-curable inks to print on a special coated film. This process enables the transfer of vibrant graphics onto a variety of substrates such as textiles, plastics, and metals, delivering high-quality, durable prints.

What are the advantages of using UV DTF printing compared to other methods?

UV DTF printing offers several advantages, including versatility in printing on multiple materials, exceptional durability against fading and scratching, and an eco-friendly approach due to lower emissions of volatile organic compounds. These benefits make UV DTF Gangheet a preferred choice for many businesses.

In what applications is UV DTF Gangheet technology commonly used?

UV DTF Gangheet technology is commonly used for promotional items, custom sports apparel, and signage. Its versatility allows for the production of high-quality prints that are durable and visually striking, making it suitable for a wide range of printing projects.

Is UV DTF printing considered an eco-friendly solution?

Yes, UV DTF printing is considered an eco-friendly solution as it does not utilize harmful solvents and has lower VOC emissions compared to traditional printing methods. This makes it an ideal choice for businesses looking to implement sustainable practices in their operations.

How does the durability of UV DTF prints compare to other printing technologies?

UV DTF prints are significantly more durable than those produced by methods like screen printing or water-based ink printing. The tough surface created by UV-curable inks ensures resistance to fading, scratching, and other forms of wear, making UV DTF Gangheet a reliable choice for high-use items.

What trends are shaping the future of UV DTF printing?

The future of UV DTF printing is shaped by advancements in technology that enhance print resolution and production speed, alongside increasing demand for custom printing solutions. As costs decrease and technology advances, UV DTF Gangheet is poised to disrupt traditional printing methods and gain broader market adoption.

| Key Point | Description |

|---|---|

| UV DTF Gangheet Technology | A method that prints graphics on coated film with UV-curable inks for vibrant, durable outputs. |

| Versatility | Can print on various materials like textiles, plastics, wood, and metals, suitable for diverse projects. |

| Durability | UV DTF prints resist fading, scratching, and wear, offering a long-lasting solution for products. |

| Eco-Friendly | Uses no harmful solvents, resulting in lower VOC emissions, making it more sustainable than many traditional methods. |

| Recent Developments | Ongoing advancements in technology are improving speed, efficiency, and print quality, increasing the market’s competitiveness. |

| Application Areas | Including promotional items, sports apparel, and signage, showcasing versatility in various sectors. |

| Market Trends | Projected significant growth due to cost-effectiveness and quality advantages, disrupting traditional printing methods. |

Summary

UV DTF Gangheet technology is revolutionizing the printing industry by providing a highly efficient and versatile solution for printing tasks. This innovative technique combines advanced UV-curable inks with a direct-to-film approach, allowing for vibrant prints on a wide range of substrates, including textiles, plastics, and metals. Its impact is notable in various sectors, especially in creating promotional materials and sports apparel. The growing trend toward eco-friendliness further enhances its appeal, as it eliminates harmful solvents and reduces VOC emissions. As UV DTF continues to evolve, it stands as a promising choice for businesses and creators who seek high-quality, durable prints while maintaining sustainable practices. Embracing UV DTF Gangheet could significantly elevate your printing projects to new heights.