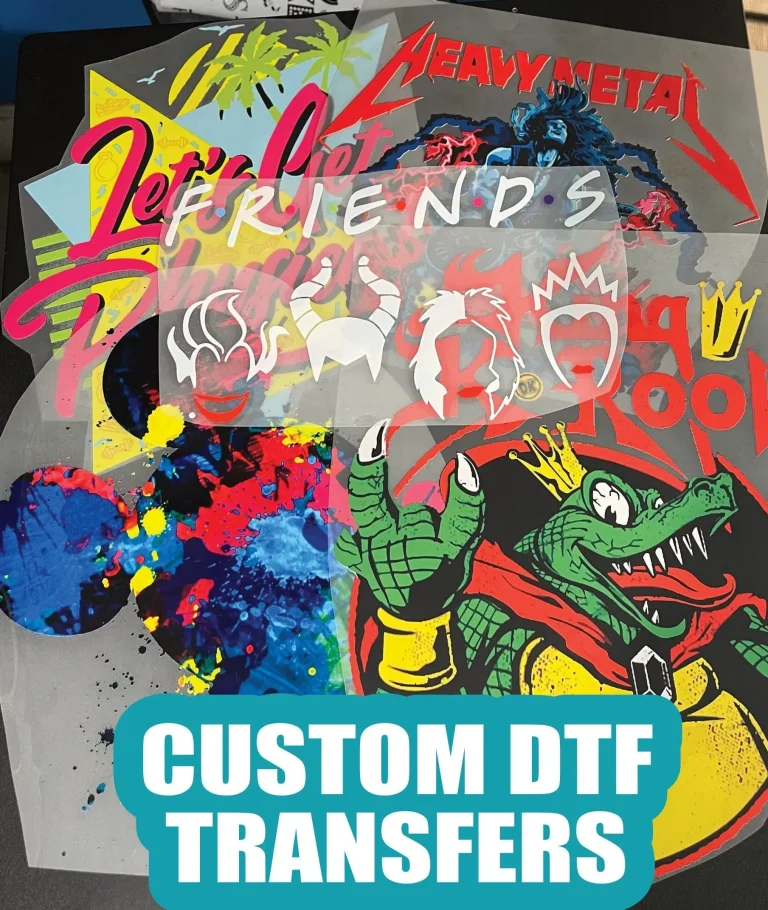

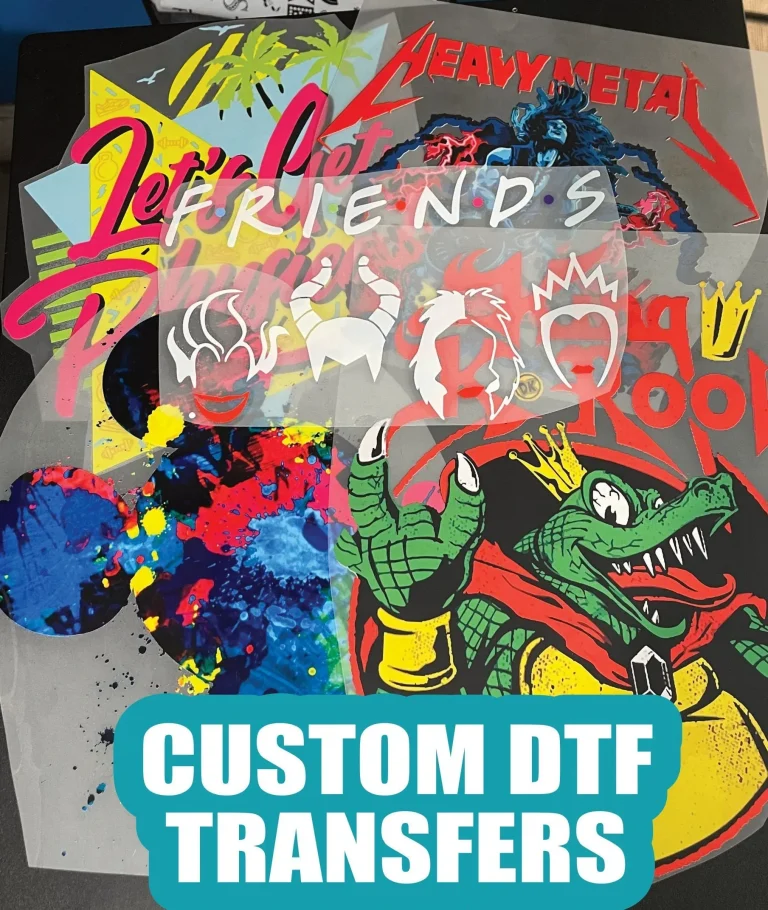

DTF Transfers, or Direct-to-Film printing, represent a revolutionary technique in the world of t-shirt customization, enabling businesses to create stunning and intricate designs with ease. This innovative printing method has quickly gained popularity among custom t-shirt businesses due to its vibrant color reproduction and versatility on various fabric types. Entrepreneurs in the garment industry can elevate their offerings by mastering DTF printing for t-shirts, turning simple ideas into eye-catching apparel. In this article, we will explore essential tips and tricks for successfully implementing DTF transfers, ensuring that your t-shirt designs not only stand out but also capture the attention of consumers. By integrating heat transfer printing techniques and best practices, you can enhance your t-shirt customization game and drive your business to new heights.

Direct-to-Film (DTF) printing is an advanced method that simplifies the process of transferring designs onto fabric, making it an appealing choice for entrepreneurs in the custom apparel industry. This technique, often known simply as DTF printing, has been recognized for its ability to produce high-quality, detailed images that are not easily achievable with traditional printing methods. Businesses focusing on t-shirt customization are increasingly embracing DTF transfers, leveraging the efficiency and vibrant design capabilities this technology offers. By understanding the essentials of heat transfer printing and the materials involved, t-shirt creators can unlock new avenues for creativity and profitability. As we delve into this topic, it’s important to consider how these printing innovations can transform a standard t-shirt into a unique piece of art that resonates with customers.

Understanding the Benefits of DTF Printing for Custom T-Shirts

Direct-to-Film (DTF) printing has transformed the realm of apparel customization, especially for t-shirt businesses. Its biggest advantage lies in its ability to produce vibrant prints with intricate details, which traditional printing methods often struggle to replicate. Because DTF transfers are printed on a special film, they retain color accuracy and clarity, making them ideal for businesses aiming to cater to fashion-forward customers who appreciate high-quality designs.

Moreover, DTF printing is incredibly versatile, allowing entrepreneurs to work on a variety of fabrics, from cotton to polyester blends. This adaptability makes it a popular choice for diverse product lines, increasing potential sales opportunities. With minimal setup required and the ability to handle smaller orders without financial strain, DTF printing offers an efficient way for custom t-shirt businesses to grow their portfolios and appeal to niche markets.

Essential Equipment for Successful DTF Transfers

To effectively utilize DTF printing, having the right equipment is paramount. Investing in a dedicated DTF printer will yield the best results, as these printers are designed to handle the specific ink and film required for high-quality transfers. Alongside the printer, high-quality DTF transfer film and adhesive powder are critical. These components work together to ensure that your designs adhere well to fabrics and remain vibrant, wash after wash.

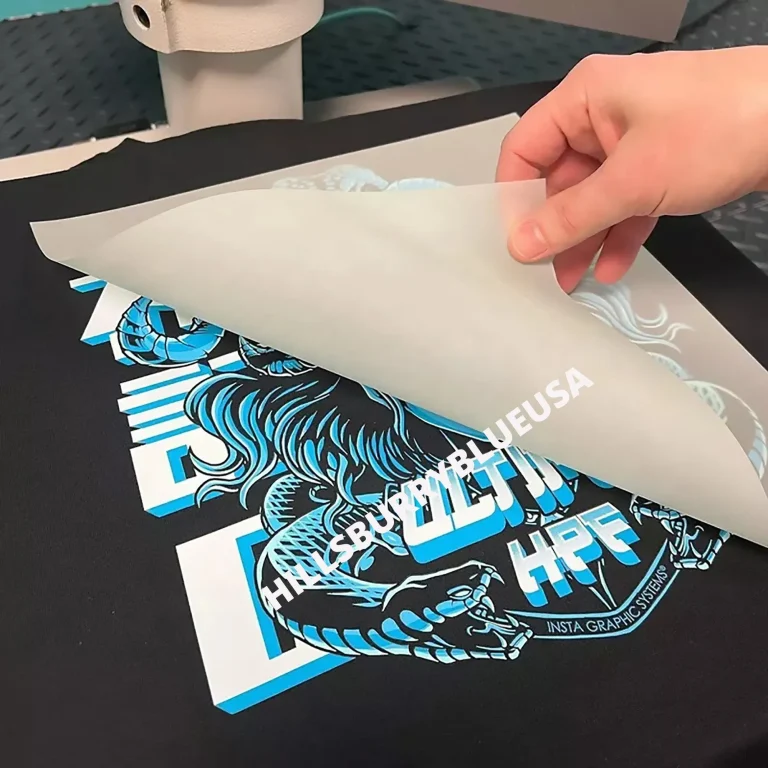

Additionally, a reliable heat press is an indispensable investment. The heat press applies the necessary temperature and pressure to activate the adhesive and bond the design to the t-shirt material. Choosing the right heat press can profoundly impact the final print quality; thus, it’s essential to select a machine with adjustable settings to cater to different fabric types and DTF transfer needs.

Design Tips for Effective DTF Printing

When designing for DTF transfers, creativity can set your t-shirt business apart from competitors. Utilizing software like Adobe Illustrator allows you to create high-resolution graphics that can be printed with precision. One critical tip is to embrace bold colors in your designs, as DTF printing allows for vibrant and eye-catching prints that can captivate consumers and elevate your brand’s aesthetics.

Incorporating intricate details is another way to enhance your designs, especially when utilizing the capabilities of DTF technology. Unlike traditional methods, DTF printing enables the application of fine lines and textures that can significantly improve the overall appeal of your t-shirts. However, it is essential to test your designs on various fabrics to ensure compatibility and to understand how colors may shift or how details will translate onto different materials.

Marketing Strategies to Promote Your DTF-Printed T-Shirts

The success of your DTF-printed t-shirts largely depends on how well you market your products. A robust social media presence can help you showcase your unique designs effectively. Platforms like Instagram and Facebook provide an excellent backdrop for sharing high-quality images and engaging with your audience. Highlight the customization aspect of your DTF transfers and encourage user-generated content to build a community around your brand.

In addition to social media, optimizing your online e-commerce platform is vital for attracting customers. Use targeted keywords related to DTF printing, such as ‘custom t-shirts’ or ‘high-quality DTF transfers,’ to improve your search engine visibility. Collaborating with influencers in the fashion and lifestyle sectors can also expand your reach, allowing your products to gain traction among potential buyers who value unique and personalized apparel.

Cost Management in Your Custom T-Shirt Business

Understanding and managing your costs effectively is crucial for achieving profitability in your t-shirt business. When incorporating DTF printing, consider all variables, including equipment, material expenses, and overhead costs. This insight will help you establish a comprehensive budget and avoid surprises that can impact your business operations.

Once you’ve mapped out your expenses, developing a competitive pricing model is the next step. Take into account the quality of your DTF transfers and the unique features of your custom t-shirts to set prices that not only cover costs but also convey value to customers. Transparent communication about the quality and customization options of your products can justify higher price points and attract discerning shoppers looking for premium apparel.

Maximizing Print Quality with DTF Technology

Achieving high-quality prints with DTF transfers involves several key processes that ensure the best results. Pre-treatment of fabrics can significantly enhance adherence, so it’s essential to choose the right method tailored to your specific fabric and transfer type. Through careful testing, you can discover the optimal pre-treatment processes that make your transfers more durable and vibrant.

Furthermore, mastering the settings of your heat press—including temperature, pressure, and time—is crucial. Experimenting with different settings during the production phase can reveal the perfect conditions for your specific designs, enhancing the final print quality. Conducting test prints with various combinations allows you to refine your technique, ensuring that each transfer meets your standards and delights your customers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technique where designs are printed onto a special film that is later transferred onto garments using heat and pressure. This method is praised for its ability to produce vibrant and detailed images on various fabric types, making it ideal for custom t-shirt printing.

What equipment do I need for DTF printing for t-shirts?

To start DTF printing for t-shirts, essential equipment includes a DTF printer, DTF transfer film, hot-melt adhesive powder, and a heat press machine. Each of these components plays a crucial role in creating high-quality prints that are durable and visually appealing.

Are there specific design tips for creating DTF transfers?

Yes, when designing for DTF transfers, it’s recommended to use bold colors to maximize vibrancy, include intricate details that highlight the technology’s capabilities, and conduct compatibility tests to ensure your designs adhere well to different fabrics.

How can I ensure the quality of my DTF printed t-shirts?

To achieve quality DTF prints, ensure proper pre-treatment of fabrics, experiment with temperature and pressure settings on your heat press, and always conduct test prints before full production to evaluate the durability and adherence of your transfers.

What marketing strategies can I use for my DTF transfer t-shirt business?

For marketing your DTF transfer products, focus on building a strong social media presence, optimizing your e-commerce platform with relevant keywords such as ‘custom t-shirts’ and ‘DTF transfers’, and collaborating with influencers to showcase your unique designs to a broader audience.

How should I price my DTF printed t-shirts competitively?

To price your DTF printed t-shirts competitively, analyze all associated costs including materials and equipment, and set prices that reflect both quality and customization. Emphasizing the uniqueness and durability of DTF transfers in your product descriptions can help justify your pricing to customers.

| Key Point | Details |

|---|---|

| What is DTF Printing? | A printing technique that transfers designs from film to garments using heat-activated adhesive. |

| Equipment Essentials | 1. DTF Printer 2. DTF Transfer Film 3. Hot-Melt Adhesive Powder 4. Heat Press Machine |

| Material Quality Matters | Choosing high-quality films and adhesives enhances print vibrancy and durability. |

| Designing for DTF | Use graphic design software, bold colors, and compatible material testing for best results. |

| Achieving Quality Prints | Pre-treatment, precise temperature and pressure settings, and test prints are crucial. |

| Marketing Your DTF Products | Utilize social media, optimize e-commerce descriptions, and collaborate with influencers. |

| Cost Analysis | Analyze materials, equipment costs, and set competitive pricing for profitability. |

Summary

DTF transfers are revolutionizing the landscape of custom t-shirt printing, offering businesses the opportunity to produce high-quality, vibrant designs at a lower cost than traditional methods. By harnessing the power of DTF technology, entrepreneurs can create unique products that not only stand out but also resonate with consumers. Emphasizing the importance of quality materials and effective design strategies is essential for success in this competitive market. Coupled with savvy marketing techniques, businesses can thrive by meeting consumer demands for personalized apparel that showcases creativity and durability.