DTF Printing Supplies are essential for anyone looking to venture into the dynamic world of Direct to Film (DTF) printing. This innovative technique has gained immense popularity for its ability to produce vibrant, long-lasting prints on textiles and various surfaces. To achieve the best results, investing in high-quality DTF printing materials, including reliable DTF printers, transfer films, and eco-friendly inks, is crucial. Whether you’re a budding entrepreneur or a passionate hobbyist, having the right tools at your disposal will not only streamline your workflow but also elevate the quality of your outputs. In this guide, we will explore the must-have supplies for DTF printing and the latest advances in technology that can help you master this creative art.

In the realm of textile printing, Direct to Film (DTF) offers a fresh approach that stands out for its efficiency and quality. Also referred to as film transfer printing, this method involves placing designs onto specially coated films that are later heat pressed onto various materials. As one of the most versatile printing techniques available today, it allows for the customization of everything from clothing to promotional items. Understanding the essential components, such as the best DTF printer, appropriate transfer films, and sustainability-focused DTF printing supplies, is key to achieving professional results. This overview will delve deeper into the necessary supplies and highlight the advancements reshaping the DTF printing landscape.

Understanding DTF Printing Basics

Direct to Film (DTF) printing is a revolutionary technique that empowers individuals and businesses to produce vibrant, high-quality prints on a variety of surfaces. This method employs a specialized transfer film designed to capture and release the ink in a way that ensures the finished product retains its color and durability, even after extensive washing. This innovation is especially appealing for those in the apparel industry, as it allows for intricate designs with excellent color fidelity and a soft finish, setting a new standard for fabric printing.

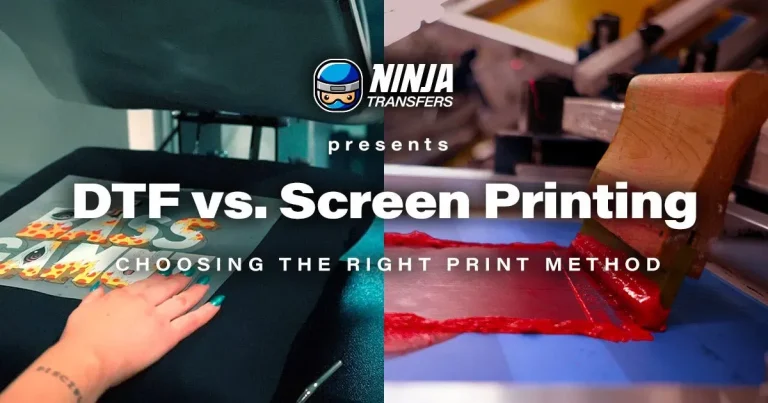

At its core, DTF printing is not just an alternative but an enhancement over traditional printing methods like screen printing and heat transfer. The process involves printing onto a transfer film, applying a powdered adhesive, and then using heat to transfer the design onto a substrate. This unique combination makes DTF printing extremely versatile, allowing for prints on cotton, polyester, blends, and even non-fabric surfaces like wood or canvas, appealing to a wide range of artistic and commercial applications.

Essential DTF Printing Supplies for Success

To get started with DTF printing, it’s crucial to invest in high-quality supplies that will ensure optimal outcomes. The most important of these is the DTF printer, which is typically a modified inkjet model designed specifically for this printing method. The best DTF printers on the market offer superior color accuracy and reliability, making them an indispensable asset for both hobbyists and professionals. In addition to the printer, you’ll need DTF inks that are water-based and specially formulated for the process, providing vibrant colors and excellent adherence to different fabrics.

Another vital supply is the transfer film, which plays a key role in capturing the ink’s detail and ensuring the design adheres to the fabric properly. The selection of transfer film can greatly impact the final results; therefore, it’s important to choose the right type that matches your fabric’s properties. Furthermore, integrating high-quality powder adhesive is essential for maintaining the print’s durability and smooth finish after transferring. Investing in robust materials will not only enhance the final product quality but also streamline the printing process, maximizing efficiency.

Exploring Eco-Friendly DTF Printing Practices

An increasing number of consumers are becoming environmentally conscious, which is influencing the printing industry to adopt more sustainable practices. In the realm of DTF printing, the development of eco-friendly DTF inks and biodegradable transfer films signifies a positive shift towards sustainability. These materials reduce the ecological footprint associated with printing processes, appealing to a market segment that values eco-conscious products.

By opting for eco-friendly DTF printing materials, print providers not only help protect the environment but can also distinguish their offerings in a competitive marketplace. Implementing such practices can enhance brand reputation and attract customers who prioritize sustainability in their purchasing decisions. The eco-friendly trend is also fostering innovation within the industry, pushing suppliers to develop greener alternatives that do not compromise on quality or durability, thereby broadening the appeal of DTF printing to a wider audience.

Understanding DTF Inks and Their Importance

When it comes to DTF printing, the choice of inks is paramount. DTF inks typically utilize water-based formulations that ensure vibrant colors and excellent adhesion to transfer films and fabrics alike. These inks not only help in achieving detailed and complex designs but also stand the test of time, offering washes and wear without fading. Selecting the right inks can make all the difference between a vibrant design and a lackluster print, thereby influencing the overall quality of the finished products.

The best DTF printers on the market are often paired with high-quality inks specifically designed for this application. Appropriate ink selection can enhance color reproduction and impact durability, making it essential to choose pigments that provide a balance of vibrancy and toughness. Understanding the chemistry behind DTF inks allows users to make informed decisions, ensuring their creative visions are translated accurately onto their chosen textiles.

The Role of Heat Press Machines in DTF Printing

A quality heat press machine is a critical component in the DTF printing workflow. The heat press applies heat and pressure to transfer the design from the film to the fabric, making it essential for ensuring proper adhesion and durability of the print. Heat presses that allow for adjustable temperature and pressure settings cater to a wide array of materials, providing flexibility for various projects including cotton, polyester, and blended fabrics.

Investing in a reliable heat press machine is vital for producing consistent results. The precision of the heat application is key to achieving a smooth and lasting finish, thereby reducing the risk of bubbling or peeling in the designs. As a result, users should prioritize heat press machines with advanced features and accurate temperature control, which will contribute significantly to achieving professional-level outputs in DTF printing.

Evolving Trends in DTF Printing Technology

The DTF printing landscape is continually evolving with advancements in technology and techniques that enhance the overall printing experience. Recent innovations in transfer film technology have led to improved adhesion properties, allowing for more versatile applications. This means that DTF printing can now extend to a broader range of surfaces, including more rigid materials like canvas and wood, increasing appeal for artists and businesses seeking diverse applications for their designs.

Furthermore, the rise of advanced software solutions is facilitating the DTF printing process. These tools enable easier management of color profiles, design files, and printing settings, providing key advantages for businesses that anticipate high levels of customization in their operations. By leveraging software that streamlines the workflow, DTF printers can significantly boost their efficiency and output quality, positioning themselves competitively within the printing marketplace.

Frequently Asked Questions

What are the essential DTF printing supplies needed to get started?

To get started with DTF printing, essential supplies include a DTF printer, high-quality DTF inks, transfer film for DTF, powder adhesive, a reliable heat press, and cleaning supplies for maintenance. Each of these components plays a crucial role in achieving vibrant and durable prints.

How do I choose the best DTF printer for my needs?

When selecting the best DTF printer, look for models that are specifically designed for DTF applications, such as modified Epson or Brother printers. Ensure the printer offers excellent customer support, is capable of high-quality color reproduction, and can accommodate the ink types you intend to use.

What type of transfer film for DTF printing should I use?

Choosing the right transfer film for DTF printing is important for achieving vibrant prints. Look for films that match the thickness and adhesive properties suited for your specific fabric types. Always opt for high-quality transfer films designed for DTF processes to maintain print integrity and color accuracy.

Are there eco-friendly DTF printing materials available?

Yes, the market for DTF printing is increasingly offering eco-friendly DTF inks and biodegradable transfer films. These materials cater to environmentally-conscious consumers and help promote sustainable practices in the printing industry without sacrificing print quality.

What is the role of powder adhesive in DTF printing?

Powder adhesive is crucial in DTF printing as it ensures proper adhesion of the ink to the fabric during the heat transfer process. Applying the adhesive after printing on the transfer film helps achieve a smooth finish and enhances the durability of the prints, making it an essential supply.

Where can I find educational resources for mastering DTF printing?

Educational resources for mastering DTF printing are widely available online. Look for blogs like Printiverse and T-Shirt Magazine for articles and tips, or explore video tutorials that demonstrate the DTF printing process. Additionally, consider enrolling in workshops or community classes to gain practical experience.

| Key Supplies for DTF Printing | |

|---|---|

| **DTF Printer** | A DTF-compatible printer uses high-quality inkjet technology tailored for DTF applications. |

| **DTF Inks** | Water-based, pigment inks ensure vibrant colors and durability on various fabrics. |

| **Transfer Film** | Specially coated sheets that hold ink until heat pressed onto fabric. |

| **Powder Adhesive** | Ensures ink adheres to the fabric during heat transfer, increasing durability. |

| **Heat Press** | A machine for transferring prints from film to fabric with adjustable settings. |

| **Cleaning Supplies** | Essential for maintaining printer efficiency and longevity through regular cleaning. |

Summary

DTF Printing Supplies are crucial for anyone looking to excel in the vibrant world of DTF printing. This innovative technique offers unparalleled quality and durability in printed designs, making it a popular choice among creators. By ensuring you have a reliable DTF printer, high-quality inks, proper transfer films, and essential equipment like a heat press and cleaning supplies, you lay the groundwork for successful projects. Furthermore, staying informed about recent advancements, such as eco-friendly inks and improved software solutions, as well as utilizing educational resources can significantly enhance your understanding and skills in DTF printing. With these tools and knowledge, you are well-equipped to produce stunning, long-lasting prints that meet customer expectations.