DTF printing, or Direct to Film printing, is at the forefront of a revolution in the fashion industry, merging creativity with technological advancement. As sustainability becomes a key concern, this printing method presents innovative solutions that address the environmental impact of traditional garment production. With DTF technology, apparel customization reaches new heights, enabling designers to create intricate and vibrant prints efficiently. The ability to respond quickly to fashion trends means that brands can minimize inventory waste while maximizing creativity. In this article, we delve deeper into the advantages and challenges of DTF printing, exploring its potential to reshape the future of sustainable fashion.

Exploring the realm of Direct to Film printing unveils a new chapter in apparel production, characterized by advanced film adhesion and rich color output. Known alternatively as DTF technology, this revolutionary method allows for on-demand fabric printing that caters to the growing trend of customized clothing. As fast fashion faces scrutiny for its environmental footprint, the adoption of eco-friendly practices in printing has never been more crucial. This article examines the implications of using DTF transfers not only for customization but also for sustainability, as brands seek to innovate while catering to consumer demands. Join us in discovering how this innovative approach to garment decoration is changing the landscape of modern fashion.

Understanding DTF Printing Technology

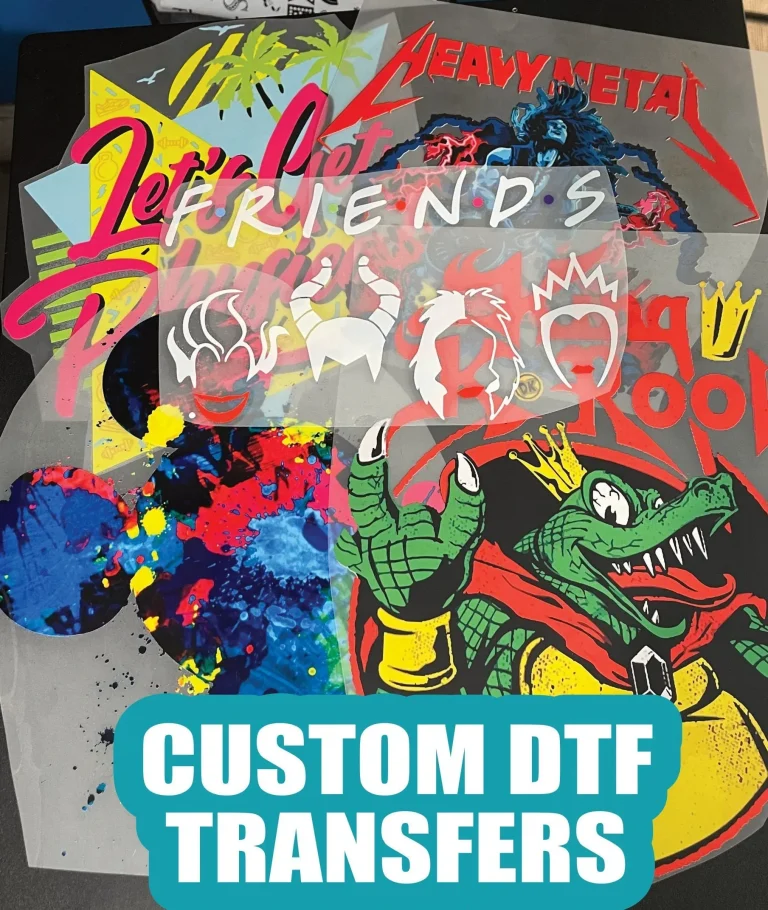

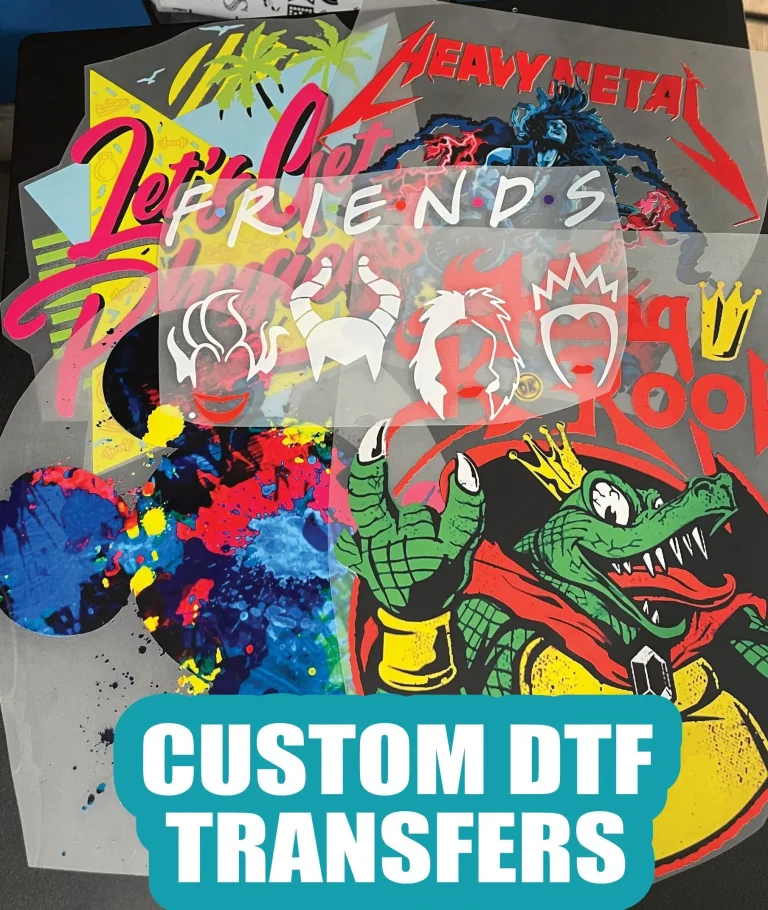

Direct to Film (DTF) printing represents a significant shift in apparel printing innovation, combining the precision of digital printing with the versatility required by modern textile manufacturers. This process involves printing high-resolution images onto a special transfer film, which is then heat-pressed onto fabric, ensuring excellent adhesion and durability. Unlike traditional methods such as screen printing, DTF allows for vibrant colors and intricate designs that can be applied to a wide range of materials, including cotton and polyester, thus vastly expanding the creative possibilities for designers.

The advent of DTF technology has streamlined the apparel printing process, enabling producers to achieve a professional finish more quickly. With the capability to produce smaller runs without sacrificing quality, DTF is particularly advantageous for brands looking to offer limited edition items or seasonal collections. This adaptability addresses the increasing demand for unique designs in the fast-paced fashion world, marking a crucial evolution in how garments are personalized and marketed.

Advantages of DTF Printing in Apparel Customization

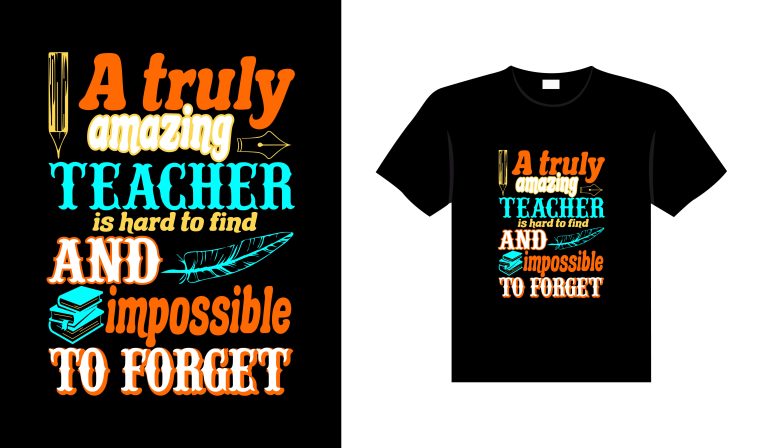

One of the standout features of DTF printing is its commitment to quality and efficiency in the customization of apparel. The printing technology is capable of yielding high-definition images with vivid colors and gradients, providing a level of detail often unattainable with traditional printing techniques. This not only enhances the visual appeal of the clothing but also meets consumer expectations for fashion items that stand out. In a market increasingly driven by personalization, DTF empowers brands to create bespoke pieces tailored to individual consumer tastes.

Beyond aesthetic benefits, DTF printing offers practical advantages for businesses. The process allows for shorter turnaround times, meaning brands can quickly respond to emerging trends or customer requests. This agility is especially critical in an era where fast fashion dominates, necessitating swift production cycles without compromising the end product’s quality. As brands harness this technology, they can enjoy improved operational efficiency and enhanced customer satisfaction.

Sustainability and Environmental Impact of DTF Printing

In recent years, the fashion industry has faced mounting pressure to adopt sustainable practices, and DTF printing appears to be a step in the right direction. This technology reduces water and chemical usage compared to traditional dyeing methods, aligning with the growing movement towards eco-conscious fashion. As consumers become increasingly aware of their impact on the planet, brands utilizing DTF printing can market themselves as environmentally responsible, which resonates with a more conscientious customer base.

However, while DTF printing offers a more sustainable alternative, the materials used in the process, including films and inks, warrant scrutiny. Ensuring that the inks and films employed are eco-friendly can enhance the sustainability credentials of brands embracing DTF. As the landscape of sustainable fashion continues to evolve, it is imperative for businesses to research and adopt practices that minimize environmental impact across the entire supply chain.

The Impact of DTF Printing on Fast Fashion Trends

DTF printing is revolutionizing the way fast fashion operates by providing rapid solutions to meet consumer trends. One of the core advantages of DTF technology is its speed; brands can produce high-quality printed garments in response to the latest fashion trends without maintaining extensive inventories. This means that retailers can keep up with fast-changing consumer preferences while reducing the risks associated with unsold stock, leading to a more responsible approach to production.

Despite the benefits, the rapid pace of production in fast fashion raises questions about overall sustainability and labor practices. Brands leveraging DTF printing must balance the need for speed with ethical sourcing and timely transparency in their operations. As shopping habits evolve and consumers demand more information about the origins of their clothing, brands that utilize DTF technology responsibly will lead the way in redefining fast fashion for a more sustainable future.

Emerging Trends in DTF Printing

As DTF printing technology gains traction, emerging trends are shaping its application in the apparel industry. Customization is at the forefront, with brands offering personalized options that cater to consumer individuality. This shift aligns particularly well with younger generations, who increasingly gravitate toward unique clothing that expresses their personal style. Brands that capitalize on this desire for self-expression through DTF can enhance customer loyalty and stand out in a competitive market.

Another significant trend is the integration of DTF printing with e-commerce platforms. Fast and efficient production capabilities enable online retailers to fulfill orders for customized apparel quickly, enhancing the shopping experience for customers. As online shopping continues to thrive, brands that leverage the advantages of DTF technology can streamline their supply chains, reducing lead times and improving customer satisfaction while tapping into the lucrative market of personalized fashion.

Quality Control Challenges in DTF Printing

Despite the benefits of DTF printing, quality control remains a critical challenge for brands adopting this technology. Consistency in print quality is paramount; discrepancies can lead to customer dissatisfaction and damage a brand’s reputation. As such, companies must implement stringent quality assurance processes throughout production. This includes employee training, regular equipment maintenance, and thorough inspections of printed items before they reach consumers.

Additionally, brands need to stay informed about the latest advancements in DTF technology to ensure their operations remain competitive. Continuous education and adaptation can help mitigate quality control issues. By prioritizing quality alongside innovation, businesses can fully harness the potential of DTF printing while building a loyal customer base.

Frequently Asked Questions

What are the key benefits of DTF printing in the apparel industry?

DTF printing, or Direct to Film printing, offers several advantages for the apparel industry, including high-quality prints with vibrant colors, durability, and wash-resistance. This technology enhances production efficiency by reducing setup times and costs compared to traditional methods.

How does DTF printing contribute to sustainable fashion practices?

DTF printing contributes to sustainable fashion by minimizing water usage during production when compared to traditional dyeing methods. As the industry moves towards sustainability, DTF technology may help brands implement eco-friendly practices, despite ongoing discussions about the environmental impact of materials used in the process.

What challenges do brands face when adopting DTF printing technology?

Brands may encounter challenges such as initial investment costs for the necessary equipment and technology, maintaining quality control during printing, and ensuring the use of sustainable materials in DTF applications. Addressing these challenges is vital for successful integration into their production processes.

Can DTF printing enhance apparel customization for consumers?

Yes, DTF printing enhances apparel customization by enabling brands to offer personalized designs tailored to individual preferences. This trend resonates particularly well with younger consumers looking for unique fashion items that express their personal style.

What is the impact of DTF printing on the fast fashion industry?

DTF printing has a significant impact on fast fashion by allowing brands to quickly respond to trends while minimizing inventory. However, this rapid production approach raises sustainability concerns, prompting brands to find a balance between speed and responsible sourcing.

How is DTF technology being utilized beyond the fashion industry?

DTF technology extends beyond the fashion industry into sectors like promotional products and home decor. Its versatility allows brands in various fields to benefit from the high-quality prints and customization options provided by DTF printing.

| Aspect | Description |

|---|---|

| What is DTF Printing? | A printing technology that uses a specialized film to transfer high-quality designs onto fabrics using heat. |

| Key Advantages | Includes vibrant colors, intricate patterns, efficiency, and reduced production costs. |

| Sustainability | Lower water usage than traditional methods, but concerns about the environmental impact of materials used. |

| Market Growth | The DTF printing market is valued at about $549.3 million in 2021, showcasing significant growth potential. |

| Challenges | Includes initial investment costs, quality control, and material sustainability issues. |

| Future Trends | Focus on personalization, e-commerce integration, and expansion into cross-industry applications. |

Summary

DTF printing is increasingly becoming a defining technology in the realm of apparel printing. By facilitating detailed and vibrant designs on various materials, DTF printing offers innovative solutions that resonate with contemporary demands for customization and sustainability in fashion. As the industry evolves, brands leveraging DTF printing can not only enhance their production processes but also align with the growing consumer expectation for environmental responsibility. This dual focus on quality and ecological impact positions DTF transfers as a significant player in shaping the future landscape of the fashion industry.