UV DTF printing, short for Direct-to-Film printing, has emerged as a game-changing technology within the printing industry, captivating businesses eager to provide customized printing solutions. This innovative approach utilizes UV DTF technology to produce vibrant and long-lasting prints on a variety of surfaces, including textiles, metal, and plastics, making it an attractive option for diverse applications. As companies increasingly focus on the benefits of UV DTF, they discover a method that not only delivers exceptional quality but also maintains cost-effectiveness in production. With the rise of personalized items, understanding the current UV printing trends can empower businesses to improve their offerings and enhance customer satisfaction. In this guide, we will delve deeper into the advantages of UV DTF printing and how it can elevate your business’s market presence.

Direct-to-Film printing, commonly referred to as DTF, is revolutionizing customization in various industries. This advanced printing technique employs UV curing to achieve remarkable durability and vibrancy in prints, setting it apart from traditional methods. As companies look for innovative ways to differentiate their products, exploring UV DTF technology can lead to unique and sustainable printing solutions. This method not only offers high-quality outputs but also aligns with current market demands for eco-friendly practices. As businesses navigate this growing trend, understanding the principles of UV DTF can unlock new opportunities for creativity and customer engagement.

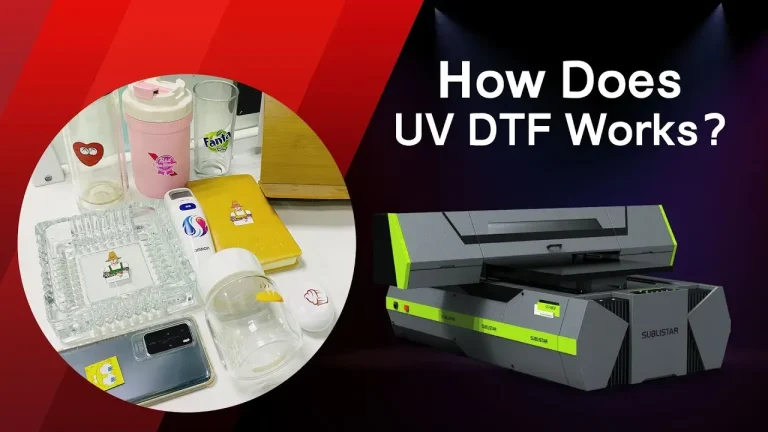

Understanding UV DTF Technology

UV DTF (Direct-to-Film) technology represents a significant advancement in the world of printing. By combining traditional digital printing with innovative UV curing processes, it produces prints that are not only vibrant but also remarkably durable. Essentially, the process involves printing images onto a specialized film using UV inks, which are then cured instantly through ultraviolet light, allowing for rapid production without the usual waiting time associated with air-drying inks. This unique method empowers businesses to create complex designs with numerous colors and gradients, ensuring that the final output is both eye-catching and high-quality.

One of the core advantages of UV DTF technology is its versatility. It can be employed on a wide range of substrates, including textiles, wood, metals, and various plastics. This adaptability allows businesses to produce custom items tailored to specific market demands, making UV DTF printing a favored choice for companies aiming to provide personalized products. As more industries recognize its potential, the technology is likely to shape the future of customized printing solutions.

Key Benefits of UV DTF Printing

One of the standout benefits of UV DTF printing is the exceptional quality and durability it offers. The UV cured inks used in this method result in prints that are highly resistant to scratches, fading, and moisture, which is particularly important for products that must endure daily wear and tear. Whether for apparel, promotional items, or decor pieces, clients can expect their prints to look vibrant and fresh over time, establishing a strong reputation for businesses using UV DTF technology.

Another significant advantage is the cost-effectiveness of the UV DTF printing process. Unlike traditional methods such as screen printing, which typically require extensive setup and larger order volumes, UV DTF printing enables companies to produce smaller quantities economically. This flexibility allows businesses to reduce waste and tailor production to customer demands more effectively. By minimizing upfront costs and inventory risks, companies can offer customized products that resonate with contemporary consumers, paving the way for greater profitability.

Sustainable Advantages of UV DTF Printing

Sustainability is increasingly becoming a priority for businesses and consumers alike, and UV DTF printing provides a compelling eco-friendly alternative to traditional printing techniques. The UV curing process emits significantly lower levels of volatile organic compounds (VOCs), making it a safer and more responsible option for the environment. By opting for UV DTF, businesses are not only enhancing their product offerings but are also contributing to a healthier planet, catering to the growing demand for sustainable products.

Additionally, UV DTF printing allows for better resource utilization. The ability to print on-demand reduces excess inventory and minimizes material waste, aligning with sustainable business practices. Companies adopting this innovative technology can market their environmental consciousness, attracting consumers who prioritize sustainability in their purchasing decisions. As such, UV DTF printing is not just about creating high-quality prints; it’s also about building a responsible brand identity in a competitive market.

Emerging Market Trends in UV DTF Printing

The emergence of UV DTF printing is closely aligned with current market trends that emphasize customization and personalization. Consumers increasingly seek unique, tailor-made products that reflect their individuality. This has driven many businesses to explore advanced printing technologies that can deliver these customized solutions quickly and efficiently. Reports indicate that the demand for UV DTF printing is rising notably in sectors such as apparel, promotional goods, and interior decor, creating new opportunities for businesses willing to embrace this innovative approach.

As more industry players integrate UV DTF technology into their operations, the overall digital printing market is expected to grow impressively. Studies suggest that as the technology matures and expands, more application areas will emerge, leading to enhanced production capabilities and quality. By keeping an eye on these trends and adapting to the changing landscape, businesses can position themselves effectively within their respective industries and leverage UV DTF to meet evolving consumer demands.

Choosing the Right UV DTF Equipment

Selecting the right equipment is a critical factor for any business considering the adoption of UV DTF printing. With various models and brands available on the market, companies should carefully assess their production needs, volume requirements, and budget constraints before making a purchase. Understanding the specific capabilities of different printers can influence output quality and efficiency, making it essential to conduct thorough research and possibly test print samples before proceeding.

Investing in high-quality UV DTF printers can significantly enhance a company’s ability to produce exceptional products. Superior equipment not only ensures better print quality and color vibrancy but also improves the reliability of the printing process, reducing downtime and operational inefficiencies. As businesses incorporate these printers into their workflow, they can benefit from an increased capacity to fulfill orders and respond to customer demands swiftly, ultimately leading to higher customer satisfaction rates.

Effective Marketing Strategies for UV DTF Products

To fully leverage the advantages of UV DTF technology, effective marketing strategies are essential. Businesses need to emphasize the unique selling points of their products, showcasing the customization options made possible through UV DTF printing. By highlighting how this technology delivers superior quality prints that can be tailored to individual customer preferences, companies can set their offerings apart from competitors and attract a more diverse clientele.

In addition to showcasing product features, marketing efforts should also focus on building brand awareness around sustainability and eco-friendliness. Communication about the reduced environmental impact of UV DTF printing compared to traditional methods can resonate with eco-conscious consumers. Integrating these narratives into social media campaigns, online advertisements, and promotional materials can create a compelling brand image that aligns with modern consumer values, thereby enhancing market reach and engagement.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or Direct-to-Film printing, combines digital printing with UV curing technology. In this method, inks are applied to a special film, which is then heat-pressed onto a variety of substrates. This allows for vibrant, durable prints on materials like textiles, wood, and plastics, making UV DTF a versatile choice for customized printing solutions.

What are the benefits of UV DTF printing for my business?

The benefits of UV DTF printing include high print quality, exceptional durability, and cost-effectiveness. UV DTF prints deliver rich colors that are resistant to fading and scratching. Additionally, this technology allows businesses to produce smaller batches, reducing material waste and production costs, making it an economically sound choice for customized products.

How does UV DTF printing contribute to sustainability?

UV DTF printing contributes to sustainability by using a UV curing process that emits fewer volatile organic compounds (VOCs) compared to traditional printing methods. This not only creates a healthier work environment but also appeals to eco-conscious consumers, enhancing your brand’s reputation while minimizing ecological impact.

What are the current trends in UV printing technology?

Current UV printing trends highlight a growing demand for UV DTF technology as businesses shift towards personalized, on-demand products. Industries like apparel, promotional goods, and home décor are experiencing notable growth due to the flexibility and quality offered by UV DTF printing, indicating its increasing relevance in the market.

What equipment do I need for UV DTF printing?

Selecting the right equipment for UV DTF printing is crucial for your business. Assess your production needs to choose a printer that meets your specific requirements for print quality and capacity. Investing in a suitable UV DTF printer will help optimize your printing operations and ensure high-quality outputs.

How can I effectively market products using UV DTF printing?

To effectively market products using UV DTF printing, focus on emphasizing customization and personalization. Showcase the unique benefits of your UV DTF printed products and use marketing strategies that highlight how they stand out in the market. Leveraging the innovative aspects of UV DTF technology can attract more customers.

| Key Point | Details |

|---|---|

| Introduction | UV DTF printing combines digital printing and UV curing technology, ideal for unique, customized products. |

| What is UV DTF Printing? | Applies inks to a film, heat-pressed onto various substrates (textiles, wood, metal, plastics). |

| High Quality and Durability | Rich colors, exceptional durability, resistant to scratches, fading, and moisture. |

| Cost-Effectiveness | Allows smaller batches, reducing material waste and production costs compared to traditional methods. |

| Sustainability | Emits fewer VOCs; a more eco-friendly option attracting eco-conscious consumers. |

| Current Market Trends | Rising demand for personalized, on-demand products in sectors like apparel and home décor. |

| Implementation Tips | Select suitable equipment, train staff effectively, and align marketing strategies with product advantages. |

Summary

UV DTF printing represents a transformative innovation in the printing industry, allowing businesses to elevate their product offerings with high-quality, durable prints. By understanding the unique benefits of this versatile technology, such as cost-effectiveness and sustainability, companies can meet the rising consumer demand for customized solutions. As reflective of current market trends, embracing UV DTF printing not only enhances operational efficiency but also positions businesses at the forefront of modern printing solutions, paving the way for future growth and success.