In the dynamic arena of fashion printing, DTF transfers have emerged as a revolutionary technique that is modifying how designs are rendered on textiles. This innovative approach, known as direct-to-film printing, allows for high-quality, vibrant designs suitable for custom apparel across various fabrics. As brands strive to meet the growing consumer demand for unique and personalized items, the DTF technique stands out for its durability and cost-effectiveness, making it a preferred choice for designers. Through this blog post, we will delve into the multifaceted benefits of DTF transfers and their burgeoning adoption across the apparel industry. Stay tuned as we unravel the potential of textile printing with DTF technology and its impact on fashion.

When we talk about the future of garment printing, direct-to-film (DTF) methods are creating a significant buzz within the industry. This modern textile transfer technique enables the seamless application of custom designs on various fabric types, catering to the evolving demands of consumers who seek personalization. By embracing alternatives like DTF transfers, fashion brands can enhance print durability and color vibrancy while minimizing costs significantly. As we explore this topic further, we will highlight how DTF printing can transform the landscape of custom apparel and redefine the standards of fashion printing.

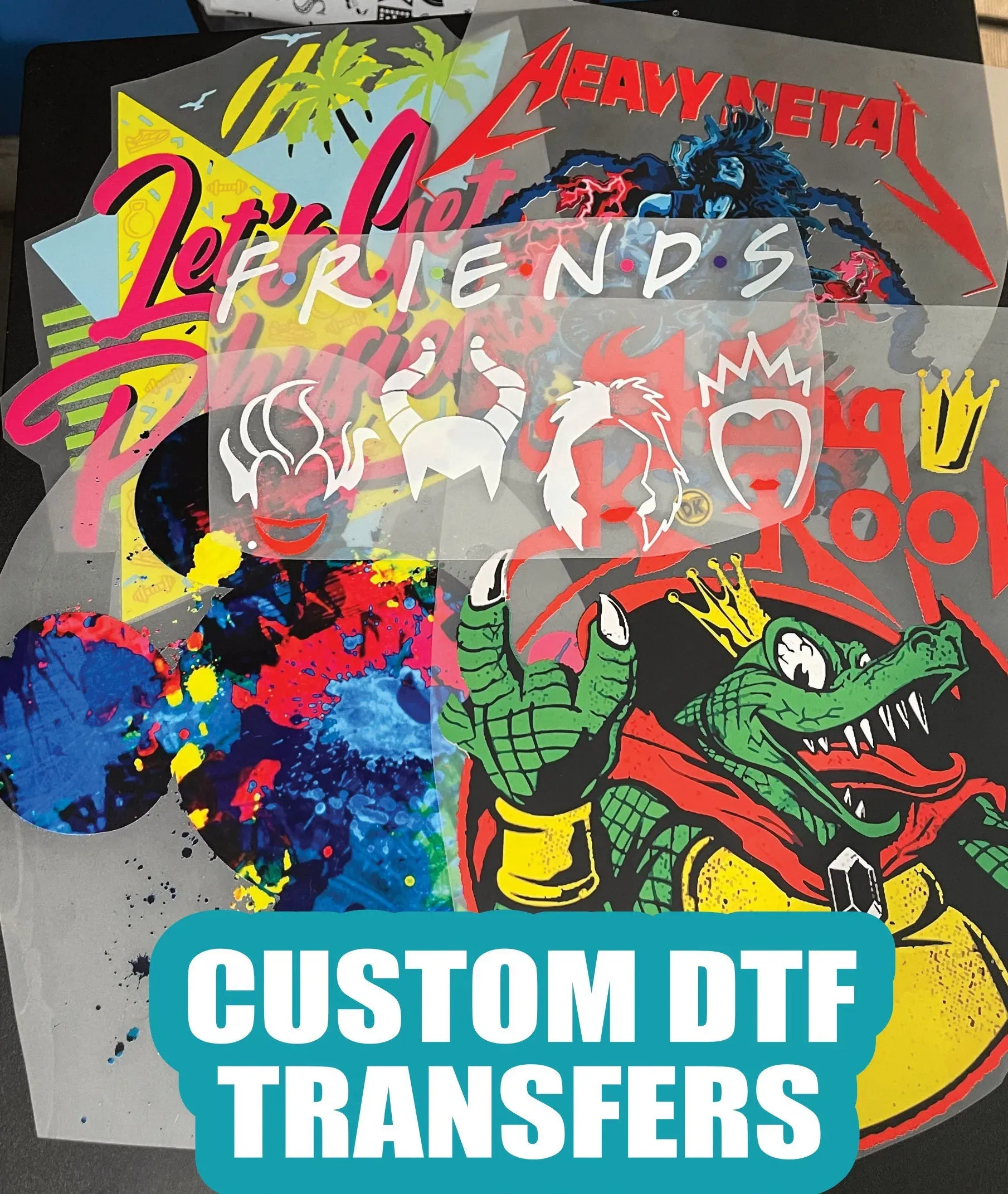

The Revolution of Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing emerges as a revolutionary technology in the realm of fashion printing, effectively changing the way creative ideas are transferred onto textiles. Unlike traditional printing methods, which often involve time-consuming processes and high material costs, DTF offers a streamlined approach that appeals to both established designers and emerging brands. This innovation not only enhances the aesthetic appeal of various fashion items but also boosts business efficiency, contributing to a more sustainable manufacturing ecosystem.

Moreover, the DTF technique allows for intricate designs and vivid color reproductions that resonate with modern consumer preferences. As fashion trends evolve towards personalization, DTF printing stands out as a valuable tool for designers who wish to create unique pieces without the limitations imposed by older printing technologies. This revolution in printing allows for immediate responses to market demands, ultimately fostering a more dynamic fashion industry.

Exploring Textile Versatility with DTF Transfers

One of the standout features of DTF transfers is their versatility across various fabric types, making them an essential tool for fashion designers. From cotton T-shirts to polyester sports gear and blended materials, DTF printing offers a broad palette of possibilities. This flexibility allows designers to explore new creative avenues without worrying about the compatibility of their prints with different textiles. With DTF, any fabric can become a canvas, enabling designers to bring their most audacious ideas to life.

Furthermore, the adaptability of DTF transfers extends beyond material types. It accommodates a range of design complexities, from simple logos to elaborate graphics, tapping into the diverse needs of the fashion market. As more brands recognize the potential of DTF technology, we are likely to see a surge in creative collaborations that emphasize textile experimentation, further enriching the fashion landscape.

Cost-Effective Solutions for Custom Apparel

DTF transfers signify a game changer in the realm of custom apparel due to their cost-effective nature, particularly appealing to small businesses and independent designers. The lower upfront costs associated with DTF technology enable creators to experiment with limited runs or niche products without incurring heavy financial burdens. This democratization of fashion printing fosters innovation and creativity among aspiring designers who wish to differentiate their offerings without compromising on quality.

Additionally, DTF’s simplicity and reduced setup time enhance its attractiveness for custom apparel production. Unlike traditional screen printing, which often involves extensive preparatory work and higher minimum order quantities, DTF allows for more agile responses to consumer trends. This responsiveness to the market not only positions brands to capitalize on current fads but also encourages sustainable practices through on-demand production.

Quality and Durability: Key Advantages of DTF Transfers

Quality and durability are paramount in the fashion industry, making DTF transfers an appealing choice for designers aiming for excellence. The DTF technique, by virtue of its method, produces prints that are not only vibrant but also retain their integrity over time, resisting fading and cracking even after numerous washes. This resilience is crucial for fashion items that are expected to endure daily wear and tear while maintaining their aesthetic appeal.

Moreover, the soft feel of DTF prints enhances comfort for the wearer, setting them apart from other printing methods that may feel stiff or heavy. This combination of high-quality output and lasting durability supports consumer satisfaction, thereby fostering brand loyalty. As consumers increasingly seek garments that combine style with longevity, DTF transfers position themselves as an optimal choice for fashion labels striving for excellence.

Emerging Trends in DTF Printing Technology

As the fashion printing landscape continues to evolve, recent developments in DTF technology signal promising directions for the industry. Innovations in printing inks and films now allow businesses to produce faster and more refined results, catering to changing consumer demands for personalized fashion items. The introduction of eco-friendly inks further enhances the sustainability of DTF printing, aligning with the growing expectation for environmentally responsible practices in the fashion sector.

Additionally, the synergy between DTF printing and e-commerce platforms is revolutionizing how designers market their products. With online customization options becoming increasingly popular, brands can use DTF technology to meet customer expectations for unique designs produced quickly and affordably. As this trend unfolds, it will undoubtedly pave the way for new opportunities and collaborations that harness the full potential of DTF in the digital retail space.

Comparative Analysis: DTF vs. Traditional Printing Methods

In the ongoing debate between DTF printing and traditional methods such as screen printing and direct-to-garment (DTG) printing, several factors come into play. DTF transfers offer unrivaled versatility and cost efficiency for small runs, enabling designers to produce customized apparel with minimal investment. In contrast, screen printing may be more suited for large-scale production where economies of scale can be fully realized, but it often comes with higher initial costs and setup time.

Moreover, while DTG printing is known for its high-quality output, it may not provide the same durability that DTF transfers offer. The comparative advantages of DTF, particularly in terms of print resilience and fabric compatibility, position it as a strong competitor in the textile printing market. Understanding these distinctions helps designers make informed decisions based on their specific project requirements, ultimately leading to more effective production strategies.

Frequently Asked Questions

What are DTF transfers and how do they work in fashion printing?

DTF transfers, or Direct-to-Film transfers, are a modern technique in fashion printing that involves printing designs onto a special film, which is then heat-pressed onto textiles. This method allows for vibrant and detailed images on various fabrics, making it a versatile choice for custom apparel.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages for custom apparel, including versatility across different fabric types, cost-effectiveness for small runs, and superior durability. This technique allows designers to create high-quality prints that resist fading and maintain comfort, catering to modern fashion needs.

How do DTF printing techniques compare to traditional methods like screen printing?

Unlike traditional screen printing, DTF printing requires minimal setup costs and is ideal for smaller batch productions. While screen printing may excel in large volume orders, DTF transfers provide more flexibility for custom designs and smaller runs while retaining high-quality output.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blended materials. This adaptability makes DTF technology suitable for various fashion items, from t-shirts to outerwear.

What recent developments in DTF technology are influencing its adoption in the fashion industry?

Recent advancements in DTF technology include improved inks and films, enabling faster and higher-quality outputs. Additionally, the integration of eco-friendly materials and the rise of e-commerce are driving more brands to adopt DTF printing to meet consumer demands for customization.

Is DTF printing a sustainable option for fashion brands?

DTF printing can be a sustainable choice due to the use of eco-friendly inks and reduced waste compared to other printing methods. As brands focus on sustainability, adopting DTF technology allows them to produce high-quality, customizable products while minimizing their environmental impact.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are reshaping fashion printing by offering innovative solutions that are versatile, cost-effective, and durable. |

| Understanding DTF Transfers | DTF printing involves printing on special film which is heat-pressed onto fabrics, creating vibrant and detailed designs. |

| Benefits of DTF Transfers | 1. Versatility across multiple fabric types (cotton, polyester). 2. Cost-effectiveness, especially for small runs. 3. Superior durability and quality, resistant to fading. |

| Recent Developments | 1. Improved inks and eco-friendly films. 2. Increased market trends and growth in DTF adoption. 3. Strong integration with e-commerce for customization. |

| Industry Insights | 1. Major brands are adopting DTF to stay competitive. 2. Comparison with screen printing and DTG methods highlights different advantages. |

Summary

DTF transfers are revolutionizing the fashion printing industry by combining flexibility, affordability, and exceptional print quality. As brands increasingly seek methods to diversify their offerings and meet the unique demands of consumers, DTF transfers stand out as a game-changer. With their ability to adapt to various fabrics and produce high-quality, durable prints, DTF transfers not only enhance product lines but also support the growing trend of customization in fashion. As technology advances and more companies integrate DTF into their workflows, we can expect this method to become a cornerstone of modern garment manufacturing, paving the way for a more dynamic and responsive fashion market.