DTF printing, or Direct-to-Film printing, is revolutionizing the world of graphic design and fabric printing, providing designers with a cutting-edge solution for creating vibrant and high-quality prints. Unlike traditional methods such as Direct-to-Garment (DTG) or screen printing, DTF printing allows for a seamless transfer of intricate designs directly onto various materials, including cotton and polyester. This innovative technique not only enhances the printing process but also caters to the ever-evolving demands for versatility and sustainability in the fashion industry. With numerous DTF printing benefits, designers are now able to experiment with a wider range of graphic design techniques and elevate their creative projects. As printing technology innovations continue to emerge, DTF printing stands as a leading method for those seeking exceptional quality and efficiency in their print endeavors.

Direct-to-Film (DTF) technology has emerged as a dominant force in modern fabric printing, captivating graphic designers with its impressive capabilities. This alternative printing method streamlines the process of applying detailed graphics onto a variety of textiles, making it an attractive choice for those in search of flexibility and high-caliber results. Known for its accessibility and economic appeal, DTF printing offers compelling advantages that dazzle creative professionals and entrepreneurs alike. As more designers discover the potential of this printing approach, they are embracing innovative patterns and techniques that align with contemporary market needs. The future of textile graphics is bright, fueled by DTF as it leads the charge toward new horizons in design and production.

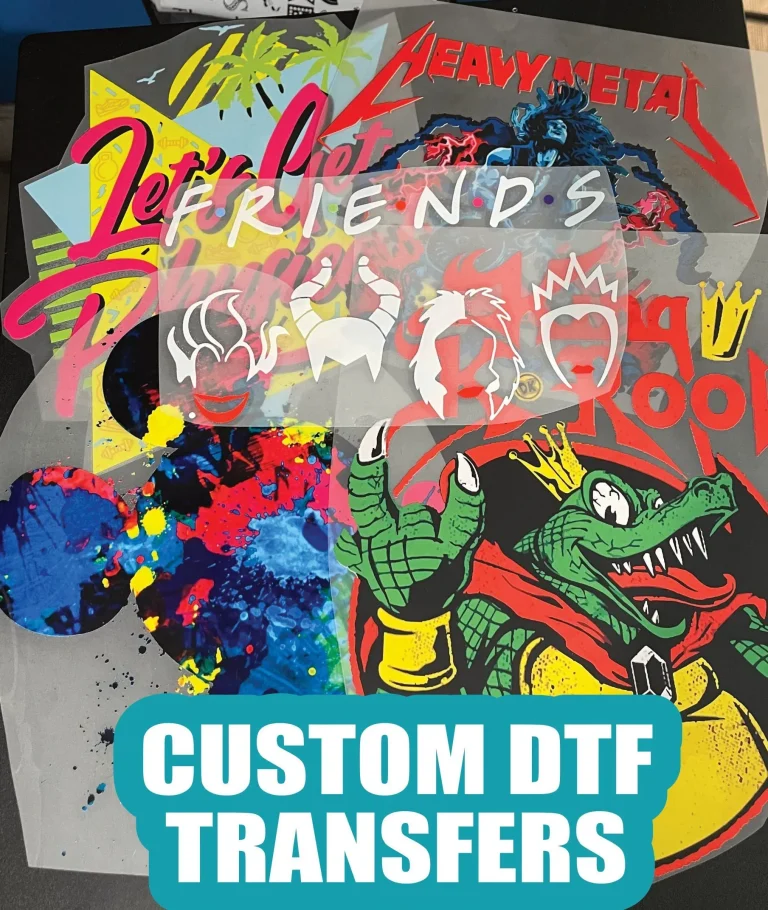

Understanding DTF Printing Technology

DTF printing, or Direct-to-Film printing, represents a significant technological advancement in the realm of textile printing. This method incorporates an innovative approach where inks are first printed onto a specialized film, which is then transferred onto a variety of fabric materials using heat and pressure. This unique process not only facilitates the production of high-resolution prints but also enables the use of vibrant, detailed designs that can captivate the viewer’s attention. Recent advancements in printing technology have further improved the efficiency and quality of DTF printing, making it a preferred choice among graphic designers.

The flexibility of DTF printing technology is one of its most notable attributes. Designers can utilize this method on diverse fabrics, including cotton, polyester, and blends, thus opening an expansive canvas for creative expression. The ability to print on different substrates allows designers to cater to various markets, whether it be fashion apparel, accessories, or custom promotional items. This versatility signifies a shift in the printing landscape, where graphic design techniques can be applied more broadly and effectively.

Key Benefits of DTF Printing for Graphic Designers

One of the standout benefits of DTF printing is its ability to produce high-quality prints that do not compromise on visual appeal. Graphic designers often seek methods that can enhance the intricacy and vibrancy of their work, and DTF printing delivers precisely that. The method allows for the creation of complex designs with sharp details and cascading color gradients, making it ideal for artistic projects where aesthetics are a priority. Furthermore, the durability of DTF prints makes them a reliable choice for designers looking to create long-lasting products that withstand wear and tear.

In addition to quality, DTF printing presents cost-effective solutions for graphic designers. With lower setup costs than traditional screen printing techniques, designers and small businesses can engage in print runs of any size without financial strain. This democratization of printing technology enables a broader spectrum of creatives to enter the market and experiment with their designs. As demand for high-quality, customizable prints increases, DTF printing equips designers with both the tools and affordability needed to thrive.

DTF Printing: A Sustainable Choice

As sustainability becomes a paramount concern in the textile industry, DTF printing emerges as a forward-thinking option for environmentally-conscious designers. Manufacturers are increasingly formulating eco-friendly inks and films used in DTF processes, thus reducing the overall environmental impact linked with textile production. This aligns with the growing consumer demand for sustainable products, making DTF printing an appealing choice for graphic designers aiming to reduce their ecological footprint without sacrificing quality.

The sustainability aspect of DTF printing is also enhanced by its efficient material usage. Unlike traditional screen printing, which often involves significant ink wastage and environmental pollutants, DTF printing can produce high-quality results with minimal resource consumption. This efficiency resonates with modern consumers who prioritize green practices in their purchasing decisions, thus positioning DTF printing as a responsible choice in the realm of graphic design.

The Role of DTF Printing in Fashion Trends

DTF printing is leaving a notable imprint on modern fashion trends by enabling designers to experiment boldly with patterns and colors. This technology allows for rapid production and customization of apparel, which is pivotal in a fast-paced fashion industry that thrives on new ideas and immediate consumer feedback. By embracing DTF printing, fashion designers can stay ahead of trends through innovative designs that resonate with their audience, ultimately leading to greater market appeal.

Moreover, DTF printing supports the development of limited edition collections and one-of-a-kind pieces, appealing to consumers’ desire for unique fashion items. The flexibility and efficiency of the DTF process empower fashion labels to explore creative avenues that were once constrained by traditional printing methods. By integrating DTF into their strategies, designers can continuously evolve their offerings to align with dynamic fashion landscapes.

Exploring Advanced Graphic Design Techniques with DTF Printing

DTF printing unlocks a myriad of advanced graphic design techniques by allowing a seamless transition from idea to physical product. Designers can now utilize sophisticated digital graphics, including intricate patterns and multi-layered typography, knowing that DTF technology can faithfully reproduce their vision with remarkable clarity and vibrancy. The ease of customization associated with DTF printing further encourages designers to push the boundaries of creativity, experimenting with various design elements to craft visually captivating pieces.

Incorporating techniques such as color blending and gradient effects is more achievable with DTF printing. Designers can take advantage of the high resolution and color accuracy provided by modern DTF printers, which can translate even the most complex designs into tangible products. This marriage of technology and artistry not only elevates the final output but also enhances the overall designer-client relationship by delivering results that exceed expectations.

Future Trends in DTF Printing

Looking ahead, the future of DTF printing appears promising with continuous innovations reshaping the landscape. As consumer demand for personalized and high-quality prints escalates, advancements in DTF technology are expected to focus on enhancing production speed and print resolution. This influx of innovations will empower graphic designers to maintain their competitive edge while efficiently catering to burgeoning market needs.

Moreover, as sustainability efforts gain traction worldwide, DTF printing is likely to evolve alongside these trends, with increased emphasis on green practices and eco-friendly materials. The fusion of advanced printing technologies with sustainable methodologies presents a unique opportunity for designers to align their practices with modern consumer values, ultimately driving the growth and adoption of DTF printing across various sectors.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a unique printing technique where designs are printed onto a special transfer film. This film is then applied to a fabric using heat and pressure, allowing graphic designers to create vibrant prints on various materials including cotton and polyester. Unlike traditional methods, DTF printing simplifies the process while enhancing detail and color vibrancy.

What are the key benefits of using DTF printing for graphic design?

DTF printing offers numerous benefits for graphic design, including versatility to print on diverse fabrics, high-quality prints with exceptional color detail, and durability that ensures long-lasting designs. Additionally, it has lower setup costs compared to traditional methods, making it accessible for both small businesses and independent designers.

How does DTF printing compare to traditional printing methods?

Compared to traditional printing methods like Direct-to-Garment (DTG) and screen printing, DTF printing is more versatile and cost-effective. It allows designers to print on a wider range of fabrics and achieves higher-quality images with intricate details. DTF printing’s simpler setup also enables quicker turnarounds, making it ideal for the fast-paced graphic design industry.

Can DTF printing be used for custom apparel production?

Yes, DTF printing is highly suitable for custom apparel production. Its ability to print on various fabrics and create vibrant designs makes it an excellent choice for fashion brands and promotional products. The method supports both small and large orders, offering flexibility for designers looking to create unique garment designs.

What recent advancements are being made in DTF printing technology?

Recent advancements in DTF printing include the development of new printer models with enhanced resolution and faster printing speeds, as well as innovations in inks that expand application ranges and improve print quality. These technological improvements are driving the rapid growth of the DTF printing market, allowing designers to push creative boundaries.

Is DTF printing environmentally friendly?

DTF printing is becoming increasingly eco-friendly, with many manufacturers developing sustainable inks and transfer films. This shift towards sustainability aligns with consumer demand for greener solutions without compromising print quality. As environmentally conscious practices grow, DTF printing is positioned to meet both designer and consumer expectations.

| Key Points | Details |

|---|---|

| Introduction | DTF printing is a revolutionary method gaining popularity among graphic designers for its ability to print directly on fabrics, offering quality and versatility. |

| Versatility | Can print on various materials (cotton, polyester, blends) without the limitations of traditional methods, enhancing creative opportunities. |

| Quality of Prints | Produces vibrant colors and intricate details, allowing for complex design execution. |

| Durability | Prints are resistant to wear and wash, ensuring longevity and resilience in clothing. |

| Lower Setup Costs | Minimized initial investment compared to screen printing, making it accessible for small businesses and independent designers. |

| Ease of Use | User-friendly operation that allows for quicker turnarounds and less training compared to other printing techniques. |

| Recent Developments | Market growth due to demand for customization, advancements in printer technology, and a shift towards sustainable practices. |

Summary

DTF Printing is revolutionizing the textile industry by providing a cutting-edge solution for designers looking to produce high-quality and vibrant prints on various fabrics. This innovative technique combines versatility with ease of use, making it suitable for a wide audience, from independent artists to large-scale manufacturers. As the trend toward sustainable practices grows, DTF printing not only meets market demands but also aligns with eco-conscious consumer preferences. Designers utilizing DTF printing can stay competitive by harnessing its durability, quality, and cost-effectiveness, all while responding to the increasing demand for customizable fabrics. In conclusion, as DTF continues to evolve with technological advancements and sustainability efforts, it is set to reshape the future of fashion and apparel production.