DTF printing, or Direct-to-Film printing, is redefining the landscape of custom printing, emerging as a game-changer for businesses and consumers alike. This innovative technology allows for high-quality garment printing, seamlessly transferring vibrant designs onto various fabrics. With a focus on flexibility and efficiency, DTF technology is particularly advantageous for small production runs, enabling detailed custom prints without the hefty setup costs associated with traditional methods. As the demand for personalized items grows, sustainable printing practices are also becoming crucial, and DTF printing’s environmentally friendly approach positions it as a responsible choice for eco-conscious brands. In this article, we’ll explore the ins and outs of DTF printing and its promising future within the custom printing industry.

Direct-to-Film (DTF) printing, a cutting-edge method revolutionizing the way we create custom designs on textiles, is capturing attention for its unique approach to garment decoration. By utilizing direct transfer techniques, this technology offers extraordinary versatility in fabric printing, allowing for an array of styles and colors to be easily applied. As we delve deeper into the nuances of Direct-to-Film printing, we will uncover its myriad advantages, including cost-effectiveness and durability, while also exploring its potential for promoting sustainable practices within the printing sector. Join us as we navigate this exciting realm where artistry meets innovation, redefining personalized apparel and promotional materials for today’s market.

Understanding the Mechanics of DTF Printing

DTF printing, or Direct-to-Film printing, is an innovative process that utilizes cutting-edge technology to bring designs to life with remarkable precision and vibrancy. This method involves printing a design onto a special film coated with a unique adhesive that targets a wide range of fabrics, such as cotton and polyester. Unlike traditional screen printing, which relies heavily on specialized setups for each color, DTF simplifies the process, making it more accessible for small businesses and custom printing enthusiasts alike. The advantages of this technology not only include efficiency in production but also the ability to achieve a high level of detail in the designs, which is crucial for brands looking to stand out in a saturated market.

The workflow of DTF printing is equally impressive, starting from creating a digital artwork that is transferred onto the film using high-quality DTF inks. These inks are typically water-based, aligning with current sustainability trends and making them an eco-conscious choice for custom printing. Once printed, the film is treated with a heat-activated adhesive powder, which, when subjected to heat from a heat press, binds the ink to the fabric surface. This process ensures that designs are not only vibrant but also durable, maintaining their quality through numerous washes and wears. By leveraging the mechanics of DTF printing, businesses can produce high-quality, personalized garments at a fraction of the cost and time compared to traditional methods.

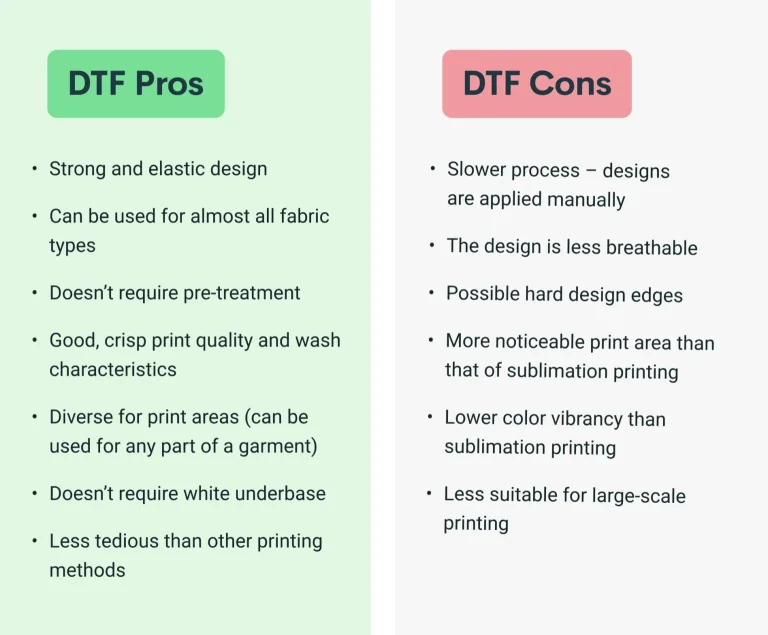

Key Benefits of DTF Technology

One of the standout benefits of DTF technology in custom printing is its unmatched versatility. Printers can work with a variety of textiles, allowing for designs on t-shirts, hoodies, bags, and other apparel seamlessly. This flexibility makes DTF printing suitable for both small-batch productions and larger orders, catering to diverse market demands. As consumer preferences pivot towards unique and personalized options, DTF technology empowers businesses to innovate without the constraints often associated with traditional printing methods, enabling a quicker turnaround time and more efficient production processes.

Moreover, the cost-effectiveness of DTF printing cannot be overstated. For small businesses and budding entrepreneurs in the custom printing space, DTF provides a budget-friendly solution that eliminates the steep upfront costs associated with screen printing. With no need for complex setup or extensive color separation, DTF allows for easier changes to designs and quicker responsiveness to market trends. This cost-efficiency, combined with the high-quality output that DTF promises, positions it as one of the most compelling options available in contemporary garment printing.

Environmental Advantages of DTF Printing

As the demand for sustainable printing solutions rises, DTF printing stands out as an environmentally friendly alternative. The use of water-based inks significantly reduces harmful emissions and lowers the ecological footprint of the printing process. Unlike traditional inks that may contain solvents and chemicals detrimental to the environment, DTF technology embraces greener practices that align with modern sustainability goals. Therefore, manufacturers and consumers alike can feel good about choosing DTF printing, knowing it minimizes environmental impact while still delivering exceptional quality.

Additionally, the DTF printing process is designed to maximize efficiency and minimize waste. Traditional garment printing methods often produce excess fabric ink that is discarded, but with DTF, the precise application of adhesive and ink results in far less waste. The scalability of DTF printing also encourages responsible consumption, as businesses can print only what they need, reducing overproduction and the associated environmental costs. This commitment to sustainable practices makes DTF a responsible choice for brands eager to contribute positively to the planet while providing high-quality products.

The Future of Custom Printing with DTF

Looking ahead, DTF printing is poised to shape the future of custom printing significantly. As technological advancements continue to enhance the capabilities of DTF printers, they will enable even more intricate designs and color options, broadening the creative horizons for designers and brands alike. The advancement of printer technology not only improves output quality but also boosts operational efficiency, ensuring that DTF remains at the forefront of printing innovations. Businesses that adopt these technologies early stand to gain a competitive edge, leveraging the transformative potential of DTF in a rapidly changing market.

Furthermore, as consumer preferences evolve towards more exclusive and personalized items, the role of DTF printing in custom apparel and merchandise will only grow. The ease of producing small runs and unique designs aligns perfectly with trends in consumer behavior, catering to a market that increasingly values individuality. With the combination of flexibility, high-quality output, and a focus on sustainability, DTF printing is set to become a cornerstone of the future custom printing landscape, empowering brands to meet the needs of the modern consumer effectively.

Challenges in Adopting DTF Printing

While DTF printing offers numerous benefits, there are challenges that businesses must navigate when adopting this technology. One of the primary hurdles is the investment in specialized printing equipment that is required for DTF. For smaller businesses, purchasing high-quality printers and heat presses can be a significant financial commitment. Additionally, the training associated with operating these advanced machines effectively is crucial, as improper handling can lead to subpar results. As such, potential adopters must weigh these initial costs against the long-term advantages that DTF printing provides.

Moreover, the pace at which technology is evolving can be daunting. The need to stay updated with the latest advancements in DTF equipment and inks is essential for maintaining a competitive edge in the printing market. As competitors innovate, there’s a constant push for businesses to upskill their workforce and upgrade their technology to meet rising expectations for quality and efficiency. Despite these challenges, the growing demand for custom, high-quality products may provide the impetus for businesses to invest in mastering DTF technology.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern custom printing technology that transfers vibrant and detailed designs onto fabrics using a special transfer film. The process begins by printing a design onto a film with water-based DTF inks. This film is then coated with a heat-activated adhesive powder, followed by applying heat and pressure through a heat press to transfer the design onto garments, ensuring a high-quality finish.

What are the key benefits of using DTF printing for garment printing?

DTF printing offers several advantages for garment printing, including flexibility to print on various materials, cost-effectiveness for low-volume orders, high-quality output with vivid colors, enhanced durability that resists fading and cracking, and a lower environmental impact due to the use of water-based inks, making it a sustainable printing option.

How does DTF technology compare to traditional printing methods?

Compared to traditional printing methods like screen printing, DTF technology is more suitable for custom printing as it requires less setup and reduces costs for small runs. DTF allows for intricate designs and vibrant colors without the need for extensive resources typically associated with traditional methods.

Can DTF printing be used on different types of fabrics?

Yes, DTF printing is highly versatile and can be used on a variety of fabrics including cotton, polyester, and blended materials. This flexibility makes DTF an ideal choice for diverse apparel products, from t-shirts and hoodies to bags and specialized garments.

Is DTF printing a sustainable printing option?

Yes, DTF printing is considered a sustainable printing option due to its use of water-based inks and reduced waste compared to traditional methods. This eco-friendly approach aligns with the growing demand for responsible manufacturing practices in the custom printing industry.

What challenges do businesses face when adopting DTF printing?

While DTF printing has many benefits, businesses may face challenges such as the need for specialized equipment and proper training for operators. Additionally, staying current with evolving DTF technology is essential to maintain high-quality production and operational efficiency.

| Key Points | Description |

|---|---|

| DTF Printing Definition | A modern printing technology that transfers designs onto fabrics using a film and eco-friendly inks. |

| How DTF Works | Involves printing a design onto a film, applying adhesive powder, and using heat to transfer onto fabric. |

| Flexibility and Versatility | Can print on various materials such as cotton, polyester, suitable for diverse products. |

| Cost-Effectiveness | Ideal for low-volume production, reducing setup costs compared to traditional printing. |

| High-Quality Output | Produces vibrant colors and intricate designs, favored by fashion brands. |

| Durability | Resistant to fading, cracking, and peeling, making it long-lasting for frequent-wash apparel. |

| Environmental Impact | Uses water-based inks and minimizes waste, aligning with sustainable practices. |

| Emerging Trends | Growth driven by technology enhancements and increasing market demand for custom merchandise. |

| Challenges | Requires specialized equipment and training, with rapid technology advancements posing challenges. |

Summary

DTF printing is an innovative solution that is transforming the landscape of custom printing. By employing advanced techniques that ensure vibrant colors and durable designs, DTF printing meets the growing consumer demand for personalized products efficiently. As businesses increasingly adopt this method, its benefits—including flexibility, cost-effectiveness, and environmental sustainability—are set to elevate the custom printing industry, making DTF printing a pivotal choice for future endeavors.