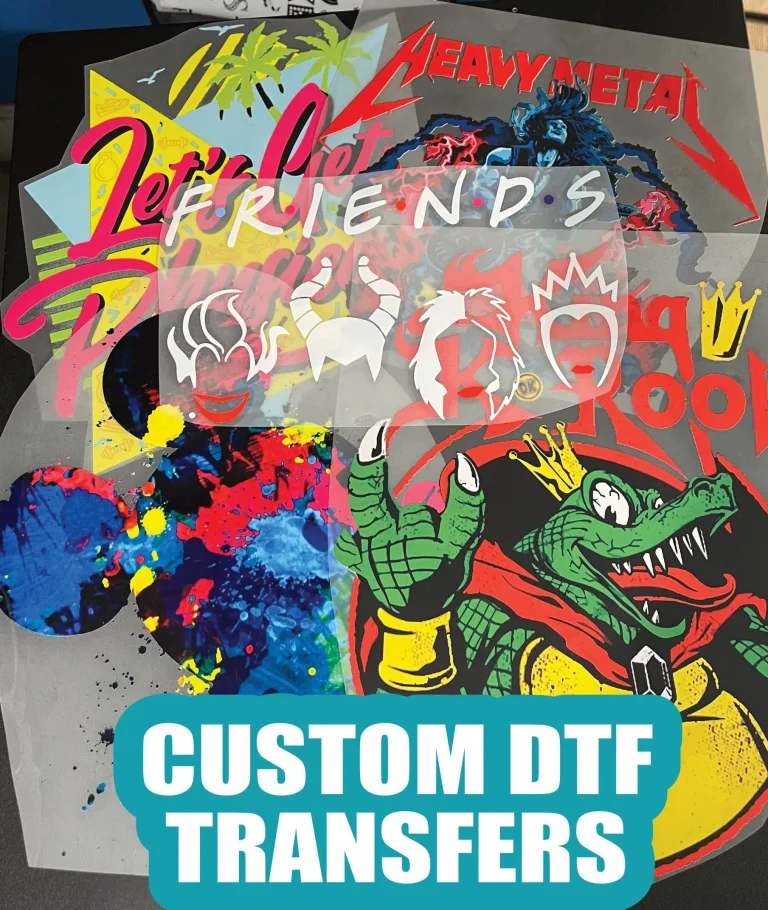

DTF Gangsheet Builders are revolutionizing the custom apparel printing landscape, making it easier and more efficient to produce high-quality prints. With the rise of DTF printing technology, these specialized builders enable designers to transfer multiple designs onto a single film sheet, significantly minimizing waste and maximizing creative possibilities. For businesses looking to stay competitive in the market, choosing the best DTF printers is crucial, as they determine the print’s quality and vibrancy. Additionally, gangsheet printing allows for a streamlined workflow that many are adopting in their custom apparel printing processes. In this article, we will explore the top DTF solutions currently available, emphasizing their features and performance.

In the realm of direct-to-film production, various terms and technologies intersect to enhance the custom apparel manufacturing experience. With advancements in DTF printing mechanisms, creators can leverage gangsheet techniques to streamline their operations by printing several designs simultaneously. This innovative approach not only introduces efficiency but also supports vibrant color reproduction, essential for captivating designs. As businesses shift towards embracing these modern methods, selecting the right printers becomes vital for achieving impressive results. In this discussion, we delve into the best options available for DTF gangsheet construction, focusing on their impact on productivity and quality.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology is revolutionizing the custom apparel printing industry. This innovative method involves printing designs onto film, which is then transferred onto fabric, allowing for vibrant colors and intricate details. Unlike traditional screen printing, DTF offers flexibility as multiple designs can be printed on a single sheet, significantly optimizing material usage and reducing waste. The technology relies on specialized inks that bond well with various textiles, providing durability and resistance to wear and tear.

As businesses look for efficient solutions in bespoke designs, DTF printing stands out with its faster turnaround times compared to conventional printing methods. The process eliminates the need for complex setups often associated with screen printing, making it ideal for small batch productions and personalized apparel. With the growing popularity of this technology, understanding its advantages is crucial for print shops aiming to expand their offerings and meet client demands for high-quality apparel.

Top Features of DTF Gangsheet Builders

When considering DTF gangsheet builders, several key features standout. Firstly, print quality is paramount; a good DTF printer should reproduce high-resolution images with vibrant colors, ensuring that designs look professional on any garment. Users should prioritize printers with advanced ink systems and high DPI capabilities, which enhance the clarity and detail of printed images. Additionally, versatility in materials is essential; printing on various fabric types ensures broader service offerings.

Another critical feature is the user interface; a printer with a user-friendly design reduces the learning curve for new users, enhancing productivity. Businesses should also evaluate the printing speed, as operational efficiency directly impacts profit margins. Lastly, the overall cost-effectiveness of the DTF gangsheet builder must be assessed, considering not just the initial investment but also ongoing expenses related to inks, maintenance, and repair.

Leading Brands for DTF Gangsheet Printing

Several brands have emerged as frontrunners in the DTF gangsheet printing market. Epson, widely regarded for its high-quality inkjet technology, offers the SureColor series, which excels in color accuracy and print sharpness. These printers are highly favored for their reliability and the ability to produce excellent results for both large and small print runs.

Roland is another significant player, particularly known for the VersaUV series that integrates seamlessly with DTF processes. Their machines are praised for high throughput and versatility, allowing for efficient gangsheet production. Additionally, Mimaki has made a name with its UJV series, which features impressive durability and color reproduction, essential for vibrant and lasting prints on textiles.

The Eco-Friendly Shift in DTF Printing

Sustainability is becoming a core aspect of the DTF printing industry as businesses are increasingly adopting eco-friendly practices. With a growing emphasis on reducing environmental impacts, manufacturers are developing inks and materials that are biodegradable and less harmful. This shift not only meets consumer demand but also aligns with global trends towards sustainable production methods.

Companies that embrace these eco-conscious solutions not only contribute to environmental preservation but also gain a competitive edge. By marketing their sustainable practices, businesses can appeal to a clientele that values eco-friendly products, expanding their market reach while promoting responsible production techniques.

Innovative Software Solutions for DTF Production

As DTF printing technology progresses, the integration of software solutions plays a vital role in production efficiency. These innovative tools assist businesses in designing layouts for gangsheeting, enabling precise placement of multiple designs on a single sheet. Automation features streamline these processes, significantly cutting down design time and minimizing errors, which is crucial for mass production.

Embracing these software solutions not only simplifies the workflow but also encourages creativity by providing users with templates and design aids. As a result, print shops can focus more on creating unique designs and expanding their service offerings, ultimately enhancing customer satisfaction and business growth in the competitive DTF printing market.

Choosing the Right DTF Gangsheet Builder for Your Needs

Selecting the right DTF gangsheet builder is critical to achieving success in custom apparel printing. Factors such as print quality, production speed, and printing cost play pivotal roles in this decision. Businesses must assess their specific requirements, whether for large-scale production or niche designs, to determine which DTF solution aligns best with their goals.

Researching different models, comparing features, and considering customer reviews are essential steps in the selection process. Ultimately, a well-informed choice of DTF gangsheet builder can lead to enhanced printing capabilities, improved product offerings, and greater profitability for businesses in the custom apparel industry.

Frequently Asked Questions

What are the best DTF gangsheet printers available?

The best DTF gangsheet printers currently on the market include the Epson SureColor series, Roland VersaUV series, Mimaki UJV series, and Brother’s DTF solutions. Each brand excels in different aspects such as print quality, speed, and ease of use, making them ideal choices for custom apparel printing.

How does DTF printing technology work?

DTF printing technology involves transferring ink onto a film which is then applied to fabric using heat. This method allows for vibrant colors and detailed designs, making it ideal for producing high-quality gangsheet prints suitable for custom apparel.

What is gangsheet printing and why is it beneficial?

Gangsheet printing refers to the process of printing multiple designs on a single sheet of film, maximizing material usage and reducing waste. This method is particularly advantageous in DTF printing for bulk orders, allowing for efficient production of custom apparel.

What should I consider when choosing a DTF gangsheet builder?

When choosing a DTF gangsheet builder, consider factors such as print quality, speed, user-friendliness, and cost efficiency. Each of these elements plays a crucial role in your overall printing success and profitability in the custom apparel market.

Can I use eco-friendly options with DTF solutions?

Yes, many DTF solutions now incorporate sustainable practices, offering eco-friendly inks and materials that minimize environmental impact. Manufacturers are increasingly focusing on sustainable options to meet the growing demand for green printing solutions in the apparel industry.

How can I improve my productivity with DTF gangsheet printing?

To improve productivity with DTF gangsheet printing, invest in high-speed printers, utilize software for design layout automation, and ensure your equipment is regularly maintained. Streamlining these processes will enhance your operational efficiency and output quality.

| Brand | Key Features | Print Quality | Speed | Ease of Use | Cost Efficiency |

|---|---|---|---|---|---|

| Epson | High-quality inkjet technology, Epson SureColor series | Exceptional color fidelity and output quality | High speed and reliability | User-friendly interface | Moderate running costs |

| Roland | Versatile, high throughput, VersaUV series | Smooth operation with reliable output | Fast printing speeds | Easy integration with DTF processes | Effective cost management |

| Mimaki | UV printing technology, UJV series | Precise color reproduction and durability | Moderate speed with high precision | Advanced features like dual ink technology | Cost-efficient for quality output |

| Brother | User-friendly, specialized for SMEs | Excellent print quality | Satisfactory speed for small to medium production | Easy to use for newcomers | Affordable running options |

Summary

DTF Gangsheet Builders play a vital role in the rapidly evolving world of custom apparel printing. The choice of the right DTF gangsheet builder can profoundly influence print quality, efficiency, and ultimately, business success. With top contenders like Epson, Roland, Mimaki, and Brother each offering unique advantages—from high-quality outputs to user-friendly designs—it’s crucial for businesses to assess their specific needs and budget. By staying informed about the latest developments in DTF technology and manufacturer features, you can select a gangsheet builder that not only enhances productivity but also contributes to sustainable practices in the printing industry.