DTF transfers, short for Direct-to-Film transfers, are fast becoming a game changer in the realm of custom printing. This cutting-edge method allows high-quality designs to be printed directly onto a specialized film before being heat transferred onto a variety of fabrics. Not only does DTF technology ensure vibrant colors and intricate details, but it also supports sustainable printing practices, aligning perfectly with today’s eco-conscious market. As the demand for personalized apparel continues to rise, DTF transfers offer an innovative solution for businesses looking to thrive in apparel printing. Join us as we explore the numerous advantages of DTF transfers and how they are setting new standards in the world of custom printing.

Direct-to-Film printing, often abbreviated as DTF printing, represents a revolutionary approach to transferring designs onto textiles. This technique encompasses a range of benefits, making it incredibly appealing in the custom apparel sector. The essence of this printing method lies in its ability to create high-quality, detailed graphics that adhere effortlessly to diverse fabric types. By utilizing advanced DTF technology, brands can not only meet market demands for bespoke designs but also promote practices aligned with sustainability. This comprehensive examination will guide you through the ins and outs of DTF transfers, shedding light on their impact within the custom printing landscape.

Understanding Direct-to-Film (DTF) Transfers

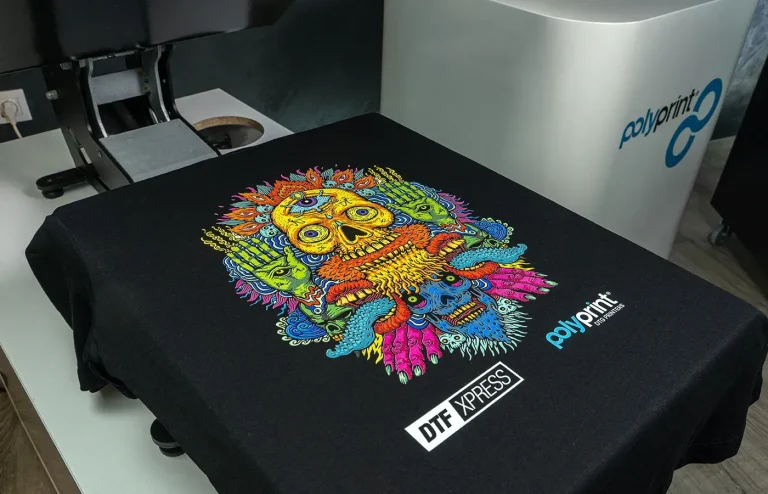

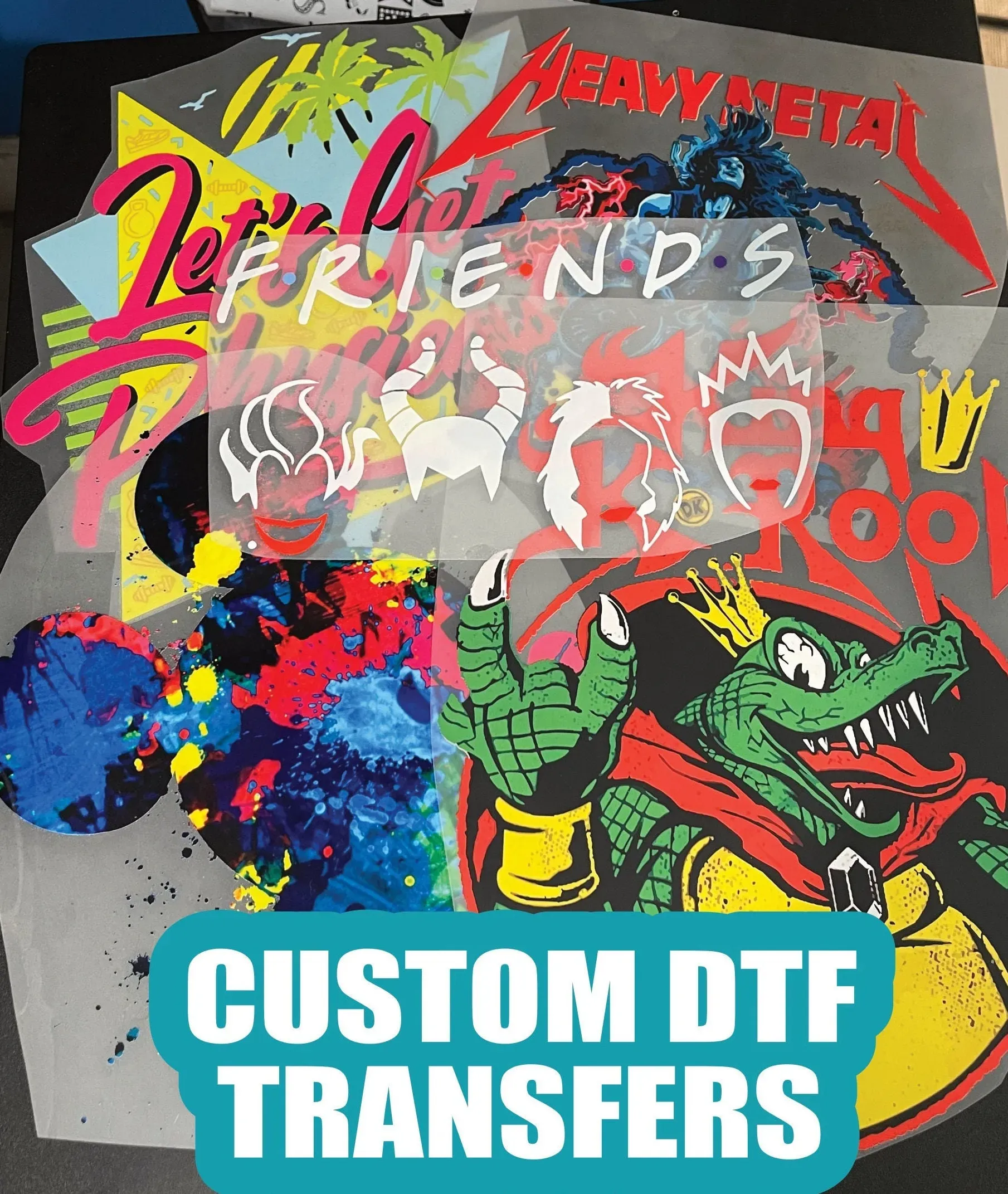

Direct-to-Film (DTF) transfers represent a significant advancement in the realm of custom printing technology. This novel method involves printing high-quality designs onto a special film that subsequently transfers to fabric using heat. DTF technology is rapidly gaining traction not only due to its ability to produce vibrant colors and intricate designs but also for its versatility across various fabric types. Unlike traditional printing methods like DTG, which can be limited in their capabilities, DTF allows for enhanced flexibility, making it suitable for a wider range of applications from apparel to promotional items.

Moreover, DTF transfers’ ability to create stunning visual outputs while being compatible with materials like cotton, polyester, or blends sets them apart in the custom printing landscape. As businesses pivot towards embracing advanced printing techniques, understanding the mechanics and benefits of DTF can be a game changer in achieving higher customer satisfaction and engagement. The seamless integration of DTF technology in existing workflows can lead to improved product offerings and elevated market competitiveness.

The Benefits of DTF Transfers in Custom Printing

One of the primary advantages of DTF transfers is their superior print quality. Recent advancements in DTF printing technology have enabled the production of incredibly vibrant colors and detailed prints that truly stand out. This enhancement of visual appeal can make a significant difference in attracting customers and fulfilling niche market demands, especially for small businesses looking to offer unique custom designs. With DTF technology, printers can cater to an array of fabric types, which allows for creating diverse products that capture consumer interest.

Furthermore, DTF transfers offer an efficient production process that aligns well with the fast-paced environment of the custom printing industry. Unlike many traditional methods that require prolonged setup times, DTF printing simplifies production, thereby accelerating turnaround times. This aspect is particularly beneficial for brands targeting time-sensitive trends or limited-edition releases. As the market grows more competitive, the ability to deliver high-quality, quickly produced items will be decisive for businesses aiming to retain and expand their customer base.

Sustainability Aspects of DTF Transfers

Sustainability is becoming an increasingly crucial factor in consumer decision-making, especially in the fashion and custom printing industries. DTF technology promotes sustainable printing practices by significantly reducing waste during production. This is primarily achieved through its print-on-demand model, which minimizes excess inventory and associated costs. By ensuring that only required quantities are printed, businesses can significantly decrease their environmental footprint, aligning their operations with contemporary consumer values.

Moreover, many manufacturers of DTF printing technology are committed to eco-friendly practices, such as using non-toxic inks and energy-efficient machinery. This emphasis on sustainability not only enhances the brand image but also attracts environmentally conscious consumers. As the industry pivots towards greener methods, companies employing DTF transfers are in a favorable position to appeal to this growing demographic, ultimately contributing to a shift towards more responsible manufacturing practices.

DTF Transfers and Market Demand

The market demand for custom printed apparel continues to surge, with consumers seeking unique and personalized garment options. DTF transfers are rapidly fulfilling this need by providing businesses with the flexibility and capabilities to produce distinctive designs that resonate with consumers. In a landscape where personalization drives purchase decisions, the ability to create customized items efficiently becomes a significant competitive advantage.

As the interest in custom apparel printing grows, so too does the necessity for rapid turnaround and quality output. DTF technology caters to this demand by offering production capabilities that can quickly adapt to various orders, from individual pieces to larger batches. By tapping into this trend and integrating DTF processes, companies are well-positioned to satisfy market needs, enabling them to thrive amidst changing consumer preferences.

The User-Friendly Nature of DTF Technology

One of the standout features of DTF transfers is their user-friendly process, making them accessible even to those new to the custom printing industry. Unlike more complex methods like screen printing or DTG, DTF printing technology allows for a simpler setup and operation. This reduces the steep learning curve for businesses starting in custom printing, allowing them to achieve quality results without extensive training or expertise.

Additionally, the DTF process facilitates on-demand printing, which alleviates the burden of managing large inventories. Businesses can print just-in-time, reducing overhead costs and potential stock waste. This practicality not only enhances operational efficiency but also aligns well with the current consumer trend toward customized and limited production runs. As more companies harness the user-friendly nature of DTF technology, they can streamline their processes and optimize their offerings effectively.

The Competitive Edge Through DTF Technology

In an increasingly competitive custom printing market, embracing DTF technology can provide a pivotal edge for small to medium-sized businesses. As mainstream manufacturers release DTF printers at accessible price points, even startups can invest in high-quality printing capabilities without breaking the bank. The reduction in equipment costs coupled with the efficiency of DTF printing presents a unique opportunity for businesses aiming to differentiate themselves in terms of quality and service.

Moreover, as more brands adopt DTF printing, the innovation within this space continues to evolve, leading to improved techniques and materials. By staying ahead of trends and investing in DTF technology, businesses not only sustain relevance in a fast-evolving industry but also position themselves as leaders in quality and customer satisfaction. This forward-thinking approach ensures that they meet consumer expectations for high-quality, affordable, and personalized products, which is crucial for long-term success.

Frequently Asked Questions

What are DTF transfers and how do they work in custom printing?

DTF transfers involve printing high-quality designs on a special film which is then heated to transfer the design onto fabrics. This method, known as Direct-to-Film (DTF) printing, ensures vibrant colors and intricate details, making it a favored choice in custom printing.

How does DTF technology enhance apparel printing quality?

DTF technology enhances apparel printing quality by delivering brighter, more vivid colors and higher resolution prints compared to traditional methods like Direct-to-Garment (DTG) printing. This is achieved through advanced printers designed specifically for DTF applications.

Is DTF printing compatible with various fabric types?

Yes, DTF printing is compatible with a wide range of fabrics including cotton, polyester, nylon, and blends. This versatility enables custom printing shops to offer an extensive selection of products to meet diverse customer needs.

What are the cost benefits of using DTF transfers for custom printing?

DTF transfers offer cost benefits by allowing small businesses to print on-demand without the need for large inventories. This minimizes bulk costs and waste, making it an economical option for fulfilling niche market demands.

How does DTF printing contribute to sustainable printing practices?

DTF printing supports sustainable printing practices by reducing waste and energy consumption during production. These eco-friendly characteristics align with growing consumer demands for responsible manufacturing in the custom printing industry.

Can DTF transfers be used for personalized designs efficiently?

Absolutely! DTF transfers allow for speedy production times and efficient customization, making them ideal for creating personalized designs in the rapidly growing market for custom apparel and unique fashion items.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a special film, which is then heat-transferred to fabric. |

| Advantages | Creating vibrant colors and intricate details with superior print quality. |

| Market Growth | DTF printing meets the rising demand for unique, customizable designs at a fast pace. |

| Fabric Compatibility | Compatible with various fabric types such as cotton, polyester, and blends. |

| User-Friendly Process | Simplifies workflow by allowing on-demand printing without extensive setup. |

| Sustainability | Reduces waste and energy consumption during the printing process. |

| Competitive Edge | Affordable access to DTF technology for small and medium-sized businesses. |

Summary

DTF transfers are redefining the landscape of custom printing by combining cutting-edge technology with market demands. This innovative method not only provides exceptional print quality and adaptability across various fabric types, but it also promotes sustainability through reduced waste and energy use. Businesses that harness the potential of DTF transfers are positioning themselves strategically in an evolving industry, fostering growth, creativity, and eco-friendly practices. The future of custom printing looks promising with DTF transfers paving the way for more personalized and sustainable solutions.