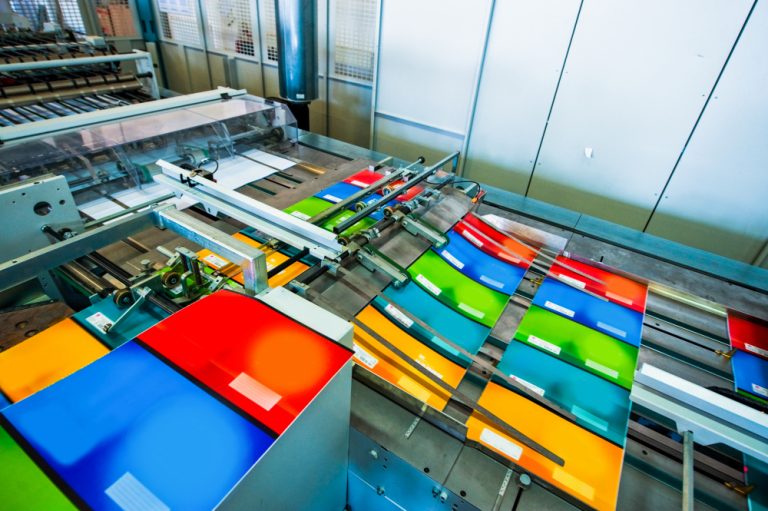

UV DTF printing is revolutionizing the printing world by combining the precision of UV printing with the flexibility of Direct to Film technology. This cutting-edge method allows for vibrant graphics to be printed on transfer films, which can effortlessly adhere to a wide range of substrates, from textiles to rigid surfaces. The advantages of UV DTF printing are numerous, including exceptional durability, rapid production times, and increased eco-friendliness due to lower emissions of volatile organic compounds. As industries continue to seek sustainable and efficient printing solutions, UV DTF applications are becoming increasingly popular in fashion, signage, and packaging. Understanding this innovative printing technology not only highlights its transformative potential but also underscores the need for businesses to adapt and thrive in an ever-changing market.

Often referred to as ultraviolet direct-to-film printing, this advanced printing methodology employs ultraviolet light for curing inks almost instantaneously, ensuring impeccable precision and vibrant color fidelity. By utilizing transfer films, manufacturers can achieve high-quality prints that apply smoothly to various materials, enhancing both aesthetic appeal and functional durability. The versatility of this printing technique makes it a go-to option for diverse applications, ranging from customized apparel to outdoor signage. Moreover, the advantages of using eco-friendly inks resonate with today’s businesses looking to diminish their environmental footprint. As the demand for innovative printing solutions rises, exploring alternative terminologies like UV DTF can further illuminate the considerable benefits offered by this leading-edge technology.

What Makes UV DTF Printing Stand Out?

UV DTF printing is a unique process that combines the best aspects of both UV printing and traditional Direct to Film methods. It employs ultraviolet light to cure the ink immediately on the film, which ensures that high-quality graphics are produced with exceptional detail and vibrancy. Unlike conventional printing techniques, where drying times can significantly delay workflow, the instant curing aspect of UV DTF printing allows for swift production cycles. Thus, businesses can meet tight deadlines without sacrificing quality, making it a preferred choice for many in the commercial printing sector.

Moreover, UV DTF printing addresses common challenges faced by traditional printing methods, such as ink adhesion and color accuracy. The advanced technology has improved film preparation processes, resulting in better ink adhesion and reduced ink waste. As a result, companies are able to produce stunning graphics that remain sharp and resilient over time, without the usual concerns of fading or smudging associated with older printing techniques. This combination of efficiency and quality sets UV DTF printing apart in the ever-evolving landscape of graphic production.

Frequently Asked Questions

What are the key advantages of UV DTF Printing over traditional printing methods?

UV DTF printing offers several key advantages, including faster production times due to instant curing with ultraviolet light, enhanced color depth for vibrant prints, and superior durability against fading and environmental factors. Additionally, it is more eco-friendly, producing less waste and containing fewer volatile organic compounds compared to traditional solvent-based inks.

How does the UV DTF printing process work?

The UV DTF printing process involves three main steps: first, a special transfer film is prepared with a receptive layer. Second, a UV printer prints the desired design onto this film while instantly curing the ink with ultraviolet light. Finally, the film is pressed onto the target substrate under heat and pressure, effectively transferring the ink.

What are the most common applications for UV DTF Printing?

UV DTF printing is versatile and used across various applications including custom apparel like t-shirts and hoodies, durable outdoor signage, innovative product packaging, and promotional materials such as banners and business cards. Its adaptability to multiple substrates makes it ideal for diverse industries.

Is UV DTF Printing an eco-friendly option for businesses?

Yes, UV DTF printing is considered an eco-friendly option. It generates less waste and has lower emissions of volatile organic compounds (VOCs) compared to traditional printing methods. This makes it suitable for businesses looking to implement more sustainable printing practices while still achieving high-quality results.

What types of materials can be printed on using UV DTF Printing?

UV DTF printing is highly versatile and can print on a wide range of materials, including textiles such as cotton and polyester, rigid substrates like ceramics and metal, and even non-porous surfaces. This flexibility allows businesses to explore various creative avenues and product offerings.

What are the recent advancements in UV DTF Printing technology?

Recent advancements in UV DTF printing technology include improvements in printer resolutions, enhanced color matching capabilities, and increased production efficiency. There is also a growing focus on sustainability, with the technology aligning more closely with eco-friendly initiatives, reflecting the changing demands of the market.

| Aspect | Details |

|---|---|

| Definition | UV DTF printing is a hybrid technique that uses UV light to cure ink on transfer films for various substrates. |

| Process Steps | 1. Film Preparation 2. Printing 3. Transfer |

| Key Advantages | 1. Versatility 2. Durability 3. Eco-Friendliness 4. Cost-Effective |

| Recent Developments | Technological improvements, market growth, sustainability initiatives. |

| Applications | Custom apparel, signage, product packaging, promotional materials. |

Summary

UV DTF Printing is revolutionizing the printing landscape by merging high-quality output with eco-friendly practices. This innovative technique not only facilitates vibrant and durable prints on a variety of substrates, but it also aligns with modern sustainability initiatives. The versatility of UV DTF printing finds extensive applications across diverse sectors such as custom apparel and signage, ensuring that no creative venture is left unexplored. As businesses and individuals continue to adapt to this advanced technology, the potential for enhanced product offerings and customer satisfaction appears limitless.