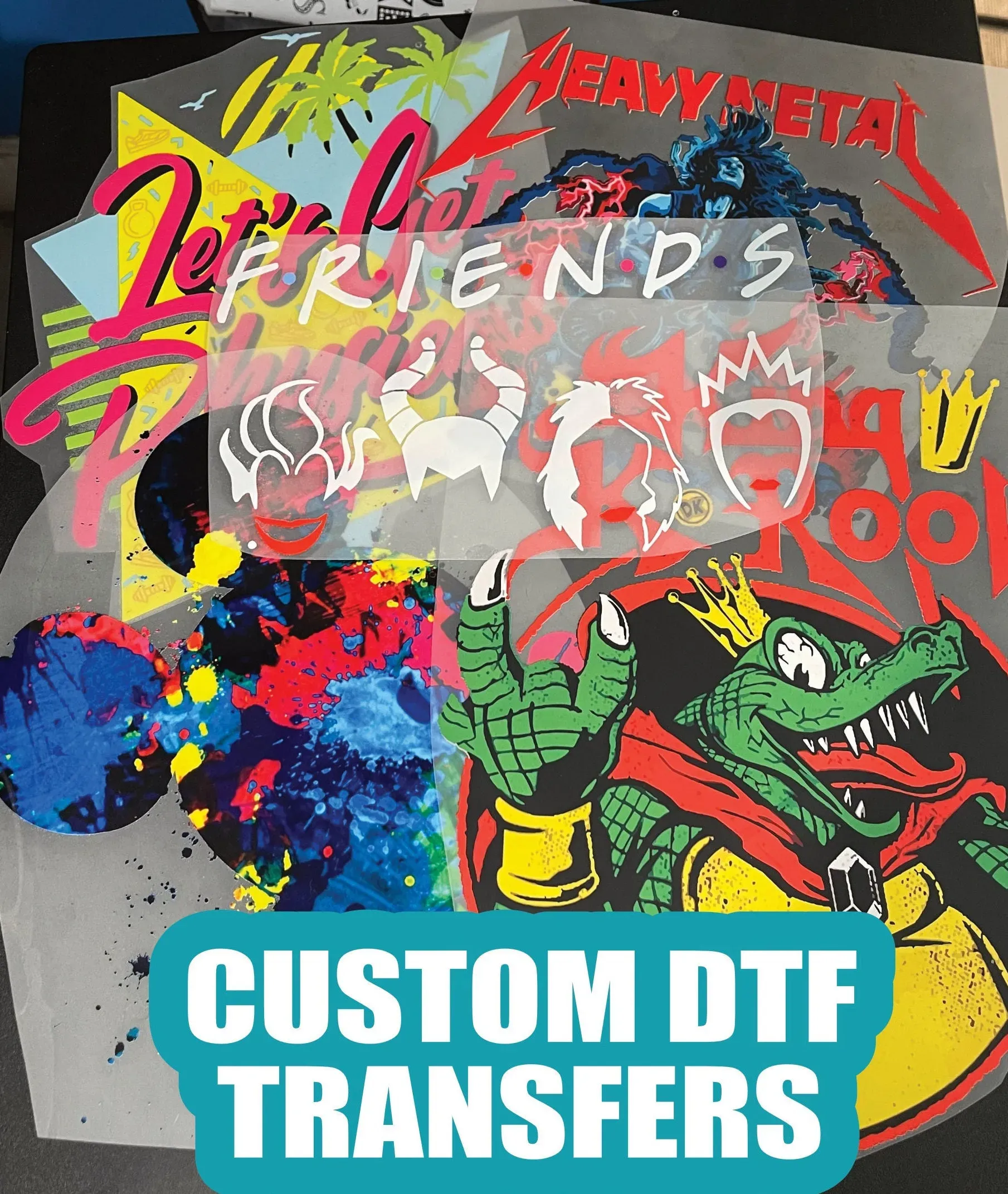

DTF transfers, short for Direct to Film transfers, are transforming the landscape of custom apparel printing with their incredible versatility and vibrant output. This innovative printing technology enables businesses to produce detailed designs that adhere seamlessly to various fabrics, paving the way for exciting fashion possibilities. With the rise in demand for personalized apparel, understanding the benefits of DTF printing is essential for anyone looking to thrive in the competitive world of custom clothing. By leveraging state-of-the-art DTF equipment, brands can deliver high-quality prints that are not only visually striking but also durable and cost-effective. As fashion printing technology continues to advance, DTF transfers stand out as a game-changer, providing new opportunities for creativity and efficiency in the printing industry.

Direct to Film transfers represent a modern strategy in the realm of garment decoration, allowing for impressive artwork to be applied to a myriad of textile options. This method of custom printing, favored by entrepreneurs and established brands alike, leverages advanced printing techniques that deliver striking visual results. With the capability to create intricate designs using minimal resources, it has become a preferred choice for those in promotional products and fashion sectors. By integrating DTF technology into their production processes, businesses can keep pace with evolving market trends while offering unique, customized apparel. As advances in this print technology continue to unfold, it’s evident that DTF is redefining the future of fashion and custom apparel.

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology has emerged as one of the most innovative approaches in the realm of custom apparel printing, making it a popular choice among businesses and creative individuals alike. Unlike traditional methods, DTF utilizes a specialized printing process where ink is applied to a film rather than directly onto the garment. This allows for precise color reproduction and intricate designs that are essential for making a lasting impression in fashion and promotional products.

The ability to print on a variety of fabrics, such as cotton, polyester, and even nylon, showcases the versatility of DTF transfers. This flexibility not only caters to diverse client needs but also expands the creative possibilities for designers looking to experiment with different textures and styles. With DTF technology, small businesses can compete more effectively in the fashion marketplace, ensuring their designs stand out.

Benefits of DTF Printing Over Traditional Methods

DTF printing offers numerous advantages that set it apart from traditional screen printing and other methods. One of the most significant benefits is its flexibility; the ability to create vibrant, multi-colored designs without the limitations of separate screens makes it an ideal choice for complex graphics. This is particularly valuable for designers who want to push the envelope with their creations, allowing for more detailed artwork and rapid adaptations to varying fabric types.

Another key advantage of DTF printing is durability. Prints created using this method are designed to withstand multiple washings without fading or peeling, ensuring that garments maintain their vibrant appearance over time. Businesses can assure their customers of high-quality products that offer longevity, making DTF an attractive option for those in the competitive custom apparel market.

Essential Equipment for DTF Transfers

To successfully implement DTF printing, certain equipment is indispensable. Firstly, a high-quality DTF printer such as those offered by Epson or Roland can make a huge difference in print clarity and color accuracy. Investing in reliable machines ensures that businesses can deliver consistent output that meets customer expectations on design and quality.

In addition to the printer, a heat press is crucial for the transfer process. It applies the necessary heat and pressure to bond the DTF film to the garment effectively. Furthermore, having good quality DTF transfer film and adhesive powder is essential, as these materials directly influence the durability and vibrancy of the final product. Crafting an efficient setup can significantly enhance production quality and speed.

Diverse Applications of DTF Transfers

DTF technology has found its niche across a multitude of sectors, significantly boosting its attractiveness for niche custom printing markets. From custom t-shirts for events to a wide range of promotional items like uniforms, DTF printing streamlines the process of creating high-quality branded apparel. This adaptability broadens the scope for businesses seeking to enhance their promotional strategies with unique and customizable products.

Moreover, the fashion industry is increasingly adopting DTF transfers for rapid prototyping and small-batch production. Designers can test new concepts quickly without the financial burden that typically accompanies bulk manufacturing. This rapid adaptability means that fashion brands can respond more swiftly to market trends and consumer demands, thus staying competitive in a fast-paced environment.

Current Trends in the DTF Printing Market

The DTF printing market is currently witnessing substantial growth, attracting attention from both entrepreneurs and larger enterprises looking to innovate their custom apparel offerings. As more businesses recognize the advantages of DTF transfers—particularly in terms of quality and efficiency—there’s an increasing demand for the technology. This trend is being driven by a rise in consumer interest for unique, personalized apparel that DTF can readily provide.

Market analysts predict that the future looks bright for DTF technology as it continues to evolve. With ongoing advancements and the introduction of new equipment that simplifies the printing process, more businesses are expected to adopt DTF printing as a standard practice in their production lines. This shift reflects broader changes in consumer preferences, as the desire for high-quality, custom items continues to grow.

The Future of DTF Printing in Custom Apparel

Looking ahead, the future of DTF printing seems exceptionally promising in the custom apparel sector. As fashion printing technology continues to refine and improve, the capabilities offered by DTF—ranging from intricate designs to vibrant color applications—will likely set new industry standards. The integration of DTF printing into a broader spectrum of fashion services positions it as a crucial tool for entrepreneurs and established brands alike.

Furthermore, with the increasing importance of sustainability in fashion, DTF printing’s relatively low waste output compared to traditional methods may also contribute to its growing popularity. Businesses seeking not just quality, but also environmentally conscious production methods, may find DTF transfers to be an ideal solution. This evolution in printing technology aligns with the changing landscape of consumer expectations and industry practices.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, utilize a specialized printing process where designs are printed onto a film using a DTF printer. Adhesive powder is then applied to the film, which helps the ink adhere to the garment when heat and pressure are applied. This method results in vibrant, durable prints that can be applied to various fabrics.

What are the benefits of DTF printing for custom apparel?

DTF printing offers several advantages for custom apparel, including flexibility for printing on multiple fabric types, excellent durability that resists fading and peeling after washing, cost-effectiveness for small production runs, and fast turnaround times that are critical for fashion and promotional items.

What equipment is needed for DTF printing?

To effectively execute DTF printing, you’ll need a specialized DTF printer (like those from Epson or Roland), a reliable heat press for transferring prints, as well as DTF transfer film and adhesive powder to ensure the ink bonds well to the fabric.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers can be used on a wide range of fabrics including cotton, polyester, and even challenging materials like nylon. This versatility makes DTF printing an ideal choice for diverse applications in custom apparel.

How does DTF printing compare to traditional screen printing?

DTF printing differs from traditional screen printing primarily in its flexibility and setup costs. DTF allows for intricate designs and multiple colors without the need for separate screens, making it more suitable for small batches and quick production without compromising quality.

What is the future of DTF printing in the fashion industry?

The future of DTF printing in the fashion industry looks promising as more businesses adopt this innovative technology. With its ability to quickly produce high-quality, customized garments at a lower cost, DTF is set to become a staple for entrepreneurs and established brands alike.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | A revolutionary method in custom apparel printing that combines versatility with high-quality output. |

| What Are DTF Transfers? | Involves printing designs onto a film with a DTF printer, followed by applying adhesive powder and heat to transfer the design onto various fabrics. |

| Advantages of DTF Transfers | Flexibility, durability, cost-effectiveness for small runs, and fast turnaround make it appealing for custom prints. |

| Equipment and Materials | Necessary equipment includes a DTF printer, heat press, DTF transfer film, and adhesive powder for successful printing. |

| Applications of DTF Transfers | Widely used in custom t-shirts, workwear, promotional items, and the fashion industry, showcasing its versatility. |

| Current Market Trends | Strong market growth as more businesses adopt DTF technology to meet consumer demands for quality apparel. |

| Conclusion | DTF transfers are an essential innovation in garment printing, providing advantages that make it suitable for various business needs. |

Summary

DTF transfers have transformed the landscape of custom apparel printing, offering a blend of quality, versatility, and efficiency. With the capability to print vibrant designs on a broad spectrum of fabrics, DTF transfers stand out as a durable option for businesses aiming for excellence in their printing processes. As the demand for custom apparel rises, understanding DTF transfers becomes crucial for anyone looking to succeed in the fashion and promotional products markets. This innovative method not only streamlines production but also ensures that creative visions come to life without the constraints of traditional printing methods. Embracing DTF technology presents a significant opportunity for growth and competitive advantage in the ever-evolving textile industry.