UV DTF (Ultraviolet Direct to Film) technology is at the forefront of a printing revolution, merging innovation with artistic expression and practicality. This advanced printing method caters to a wide range of applications, from custom apparel to unique home decor, enabling users to realize their creative visions like never before. By utilizing UV DTF printing, businesses can achieve striking, high-resolution graphics that are durable and vibrant, making it an ideal choice for those seeking high-quality custom DTF designs. Moreover, as the demand for sustainable apparel rises, this eco-friendly technology uses less ink and water than traditional methods, appealing to environmentally conscious consumers. In this article, we will delve deeper into the exciting possibilities UV DTF offers across various industries.

Exploring ultraviolet direct printing techniques reveals an exciting landscape for creativity and customization in the printing field. Known for its efficiency, UV DTF technology allows practitioners to produce intricate designs on a variety of surfaces, ranging from clothing to decorative items for the home. As businesses increasingly seek personalized solutions, custom direct-to-film designs have become increasingly popular, delivering exceptional results across sectors such as fashion and furniture. Furthermore, the sustainable aspects of this printing innovation align perfectly with the modern consumer’s values, marrying style with eco-friendliness. In the upcoming sections, we will highlight the transformative impact of this technology on various applications and its role in promoting sustainable practices.

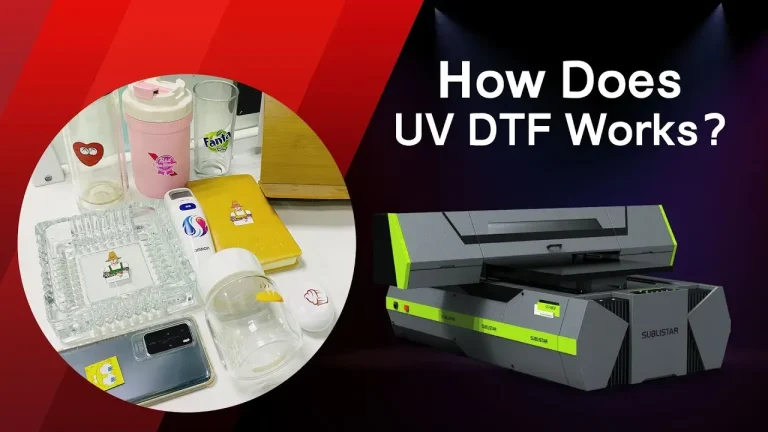

Understanding UV DTF Technology: A Game Changer in Printing

UV DTF technology, short for Ultraviolet Direct to Film, is an innovative printing method that employs ultraviolet light to cure specialized inks onto a variety of surfaces. This process is revolutionizing the printing industry by allowing for the production of high-quality, vibrant images with intricate details. One of the major advantages of UV DTF is its ability to print on numerous substrates, including textiles, wood, and metals. This level of versatility makes UV DTF a popular choice among businesses looking to enhance their product offerings with customization options.

Furthermore, the speed at which UV DTF prints are produced is impressive, as traditional drying times are virtually eliminated. This rapid turnaround facilitates quicker fulfillment of consumer orders, which is particularly beneficial in industries where speed is paramount. Additionally, the durability of UV DTF printed items is noteworthy; the cured inks are resistant to fading and damage, ensuring that the beautiful designs last longer and maintain their appeal.

Creative Customization: The Impact of UV DTF in Apparel Design

The UV DTF printing process has significantly impacted the fashion industry, empowering designers and brands to create personalized clothing that resonates with their customers. Thanks to its ability to produce high-resolution graphics with vivid colors, UV DTF is perfect for printing elaborate custom designs on garments. This technology allows designers to push the boundaries of creativity, offering unique pieces that captivate consumer attention and meet their demand for personalization.

Moreover, UV DTF’s environmentally friendly attributes are attracting fashion brands keen on adopting sustainable practices. The process minimizes waste and reduces water usage compared to traditional printing methods. As consumers become more environmentally conscious, they are more likely to support brands that prioritize sustainable apparel solutions. The merger of high-quality prints and eco-centric practices positions UV DTF as a strategic asset for brands looking to innovate while being conscious of their environmental impact.

Transforming Home Decor: UV DTF Applications Beyond Clothing

In addition to apparel, UV DTF technology has opened new doors in the home decor sector. From custom wall art to personalized furniture designs, the versatility of UV DTF allows homeowners to express their individual tastes through customizable home accessories. Utilizing this technology, designers can produce stunning prints that can be applied to a variety of surfaces, enabling the creation of unique and stylish home settings.

Custom textiles, such as throw pillows and curtains, can also benefit from UV DTF printing, giving consumers a chance to incorporate exclusive patterns and images into their living spaces. As more individuals seek to make their homes reflect their personality, the demand for UV DTF in home decor continues to grow, making it a vital tool for interior designers and decorators looking to offer tailor-made solutions.

Promotional Power: Elevating Brand Visibility with Custom DTF Designs

Businesses are increasingly turning to UV DTF technology to create memorable promotional products that help enhance brand visibility. The ability to produce high-quality, customized items such as tote bags, mugs, and promotional apparel allows companies to leave a lasting impression on their target audience. Custom DTF designs ensure that logos and branding messages are printed with precision and vivid clarity, helping organizations stand out in crowded marketplaces.

Furthermore, UV DTF’s compatibility with various materials means that businesses can utilize this technology for a diverse range of products, giving them flexibility in marketing strategies. From corporate gifts to trade show giveaways, the potential for UV DTF to aid in brand promotion is vast, making it a valuable investment for companies aiming to strengthen their market presence.

Durability and Reliability: The Industrial Advantages of UV DTF Printing

The industrial sector is beginning to recognize the many benefits that come with UV DTF printing technology. With its resilience, UV DTF can create durable labels and markings that endure the stresses of industrial environments. This makes it ideal for high-demand applications, such as tool and machinery markings, where visibility and legibility are crucial for compliance and safety standards.

Moreover, UV DTF offers customization for equipment used in various industries. By incorporating distinct branding elements onto tools and machinery, companies can enhance their identity and reduce the chances of misplacement. The ability to create bespoke prints ensures that equipment stands out, reinforcing brand visibility while providing a practical solution for identifying essential tools.

Future Trends in UV DTF Technology: Embracing Innovation and Growth

As the demand for customization and personalized products continues to rise, UV DTF technology is set to experience remarkable growth in the coming years. Emerging advancements in printing methods and materials will further enhance the capabilities of UV DTF, allowing for even more intricate and high-quality outputs. Ongoing research and development within the industry promise to optimize production efficiency, making it more accessible for businesses of all sizes.

Furthermore, the trend toward sustainability in manufacturing is more pertinent than ever, and UV DTF’s eco-friendly attributes align perfectly with this market shift. As innovative solutions emerge, businesses that adopt UV DTF will not only benefit from high-quality printing but also show a commitment to environmental responsibility, positioning themselves favorably among conscious consumers. The future is bright for UV DTF, paving the way for exciting applications across various industries.

Frequently Asked Questions

What is UV DTF technology and how does it work?

UV DTF technology, or Ultraviolet Direct to Film printing, uses ultraviolet light to cure inks onto various surfaces. This method allows for vibrant, long-lasting images to be printed on materials such as fabrics, wood, metal, and glass without the lengthy drying times associated with traditional printing methods.

How does UV DTF printing benefit sustainable apparel production?

UV DTF printing promotes sustainable apparel production by using fewer raw materials and significantly reducing water consumption compared to traditional textile printing methods. This eco-friendly approach appeals to brands and consumers looking to make environmentally conscious choices in their fashion selections.

Can UV DTF technology be used for custom DTF designs in home decor?

Yes, UV DTF technology is perfect for creating custom DTF designs in home decor. It allows for high-resolution prints on a variety of surfaces, making it ideal for personalized wall art, furniture designs, and unique home accessories that reflect individual tastes.

What are the advantages of using UV DTF printing for promotional products?

The advantages of UV DTF printing for promotional products include the ability to print on a wide range of materials, creating professional-quality designs that enhance branding. This versatility allows businesses to produce customized items that stand out at corporate events, trade shows, and marketing campaigns.

Is UV DTF technology suitable for industrial applications?

Yes, UV DTF technology is well-suited for industrial applications, providing durable labeling and markings on tools and machinery. This ensures that brands remain visible and compliant with safety standards, while also allowing for customized prints to enhance equipment identification.

What recent developments are driving the growth of the UV DTF printing market?

Recent developments in UV DTF technology, including advancements that improve printing efficiency, quality, and speed, are driving market growth. Increased demand for personalized and diverse applications across industries like fashion and home decor is further propelling the expansion of the UV DTF sector.

| Key Points | Description |

|---|---|

| What is UV DTF Technology? | UV DTF uses ultraviolet light to cure inks, allowing for vibrant, high-resolution graphics on various materials without lengthy drying times. |

| Creative Applications | – Apparel: Personalized fashion and sustainable practices. – Home Decor: Custom wall art, furniture design, and textiles. – Promotional Products: Enhanced branding and versatile materials. – Industrial Applications: Durable markings and customized equipment. |

| Market Growth | The UV printing market is projected to grow at a CAGR of 10.5%, fueled by technological advancements and increasing consumer demand for personalization. |

Summary

UV DTF technology is revolutionizing the printing industry, offering innovative and customizable solutions that cater to diverse applications such as apparel design, home decor enhancement, promotional items, and industrial markings. As the enforcement of sustainable practices and technological advancements gain momentum, UV DTF’s flexibility and efficiency become key drivers for businesses and creators looking to distinguish themselves in the market. This technology not only empowers consumer personalization but also aligns with eco-friendly initiatives, providing a vital competitive edge in today’s marketplace. The ongoing growth of the UV DTF sector reflects the increasing demand for unique and high-quality prints, promising exciting opportunities for all involved.