The DTF Gangsheet Builder is a revolutionary tool that empowers apparel printers to optimize their designs with precision and efficiency. This innovative solution streamlines the Direct to Film (DTF) printing process, allowing you to maximize output while minimizing material waste. By mastering effective gangsheet design, you can create vibrant, high-quality prints that will captivate your customers and elevate your brand. In this guide, we will explore essential DTF printing tips and gangsheet layout tips that can transform your printing workflow. Whether you’re new to custom apparel printing or a seasoned professional, these insights will help you harness the full potential of the DTF Gangsheet Builder for striking results.

The DTF Gangsheet Builder represents a cutting-edge approach to custom garment production that maximizes design efficiency. This powerful software aids in the creation of cohesive layouts for Direct to Film printing, ensuring each print area is utilized effectively. Understanding effective design principles and incorporating handy printing tips can dramatically enhance the quality of your fabric transfers. By following strategic gangsheet layout practices, you can achieve consistent and vibrant results that set your apparel apart. Whether you’re starting in the world of textile printing or looking to refine your technique, familiarizing yourself with this essential tool is key to your success.

Maximizing Efficiency with DTF Gangsheet Builder

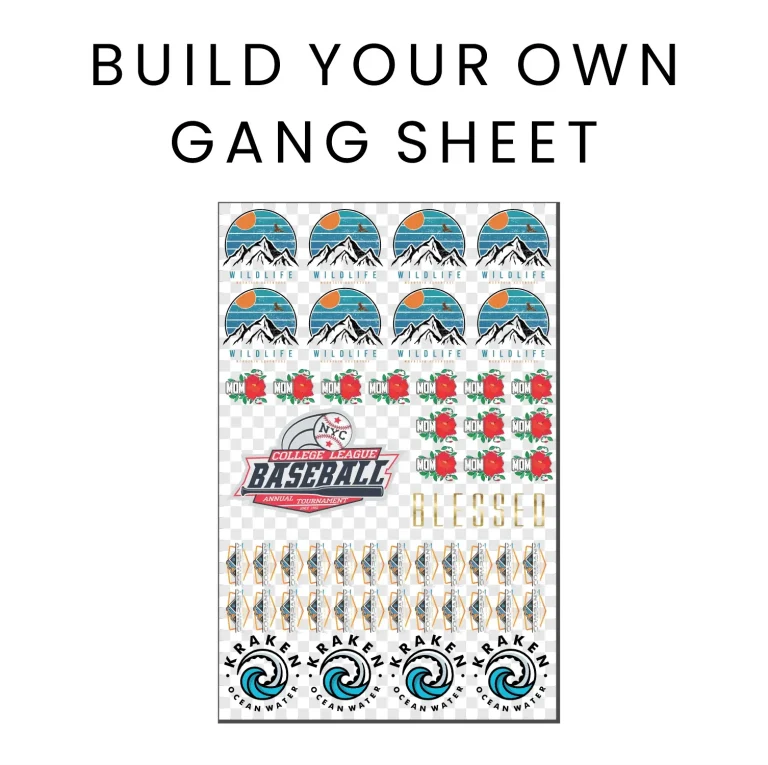

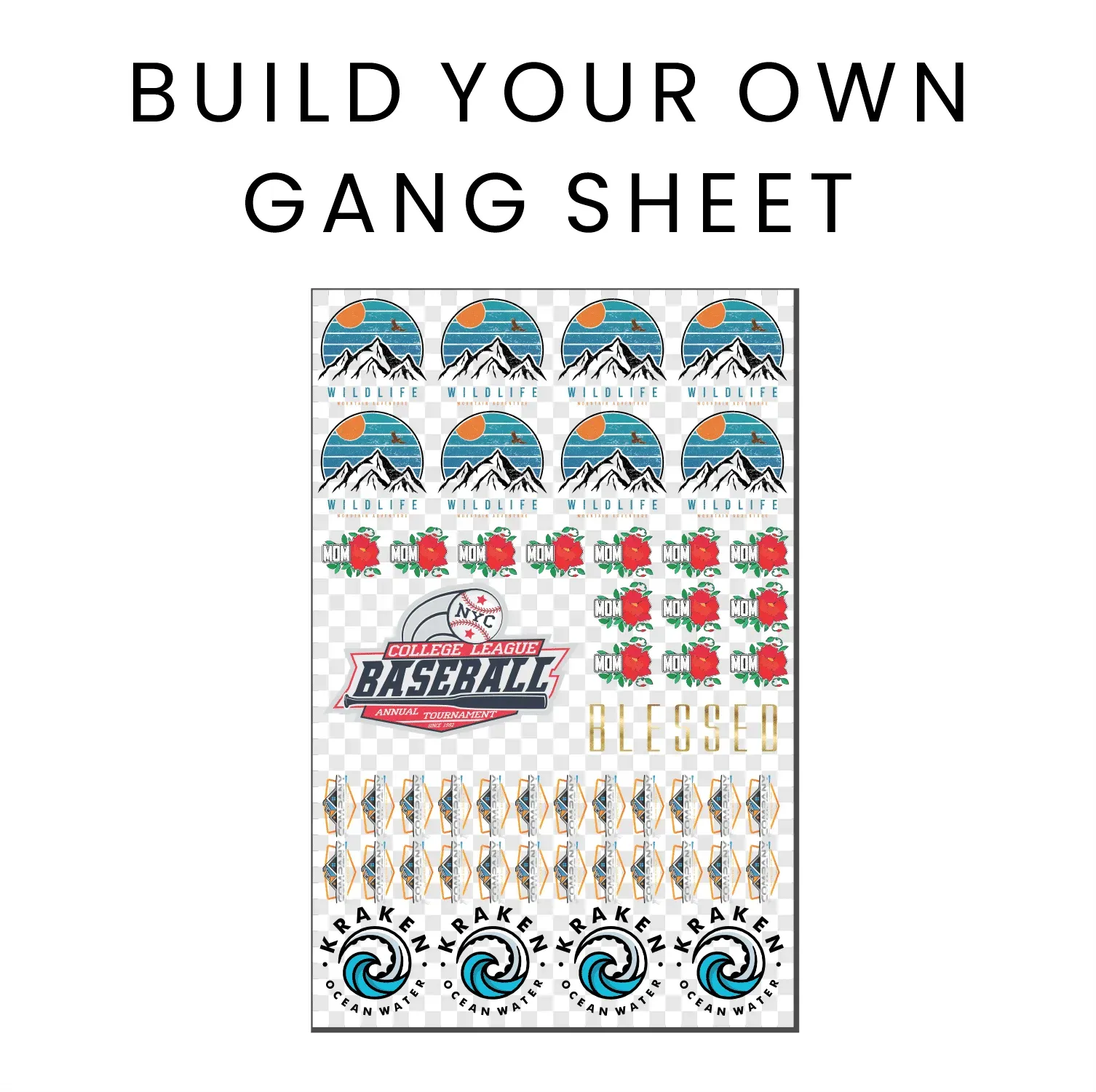

To maximize efficiency with the DTF Gangsheet Builder, it is essential to understand how to organize your designs on the gangsheet effectively. One useful approach is to group similar designs together, which allows for quicker production and minimizes waste. This organization not only speeds up the printing process but also enhances the overall quality of your prints by ensuring that similar materials and colors are printed together. Additionally, employing a systematic layout can help you avoid common pitfalls, such as misalignment and excess trimming, which could compromise your final output.

Furthermore, an efficient gangsheet design can drastically reduce the time spent processing different fabric types. By streamlining your workflow in this manner, you can reduce the switching time between different settings and print jobs. Utilizing a grid layout can also be a wise choice, as it helps ensure that all designs are placed accurately, which leads to consistency in final products. Overall, understanding how to maximize your DTF Gangsheet Builder setup will significantly contribute to productivity and quality in your custom apparel printing.

Essential DTF Printing Tips for Beginners

For those new to DTF printing, familiarizing yourself with essential DTF printing tips is crucial. Start by investing in high-quality DTF inks and films, as these directly affect the clarity and durability of your prints. Using inferior materials can lead to underwhelming results, such as faded colors and poor adhesion to fabrics. Additionally, adjusting your printer settings according to the specifications provided by film manufacturers will not only enhance print quality but will also extend the life of your printer.

Moreover, beginners should not overlook the importance of learning from experienced users. Engaging with communities and resources, such as online forums or tutorial videos specifically about DTF printing, can offer invaluable insights. These platforms often share troubleshooting advice and advanced tips that can help you navigate potential challenges in your printing journey. By gathering knowledge and best practices, novices can improve their skills and lead to a successful venture in custom apparel.

Effective Gangsheet Layout Techniques

Creating effective gangsheet layouts is pivotal for achieving great results in DTF printing. One crucial technique is to use vector graphics exclusively for your designs, as they maintain quality no matter the size adjustments made. When laying out your designs, be sure to leave adequate space between them to avoid cutting into neighboring graphics during the transfer process. This strategy not only preserves the integrity of your designs but also optimizes the use of available space on the gangsheet.

Additionally, color management plays an essential role in effective gangsheet layouts. Different fabrics absorb inks differently, so it’s important to understand how color appearance may change once printed. Use a calibrated color profile to ensure consistency in color reproduction across various materials. Employing these layout techniques will lead to more vibrant and accurately represented designs in your final products.

Streamlining Your Production Workflow

Streamlining your production workflow is crucial if you want to make the most out of your DTF printing capabilities. To achieve this, sort your designs based on popularity and fabric types, which can significantly reduce time spent when preparing to print each batch. By prioritizing frequently requested designs, you can ensure a continuous workflow that meets customer demand without unnecessary delays, allowing for efficient operation in your print shop.

Incorporating feedback mechanisms into your workflow is another handy strategy for ongoing improvement. After each production run, seek feedback from quality control checks, or solicit opinions from your team on potential areas of enhancement. This practice cultivates a culture of consistent quality and encourages collaboration, making it easier to identify and rectify any issues quickly. Such adaptive methods not only improve individual prints but also elevate the overall standard of your custom apparel.

Utilizing Software for Enhanced Design

Harnessing the power of graphic design software can dramatically enhance the efficiency and quality of your designs for DTF printing. Programs like Adobe Illustrator and CorelDRAW are highly recommended for DTF printing due to their robustness in handling vector graphics, which are essential for clean designs. These software tools provide functionalities that allow you to create multiple templates or presets tailored to your gangsheet needs, saving you significant time in design preparation.

Moreover, utilizing design software ensures that you’re using best practices for file preparation, such as converting fonts to outlines to prevent printing issues. Over time, developing familiarity with these tools will allow you to experiment with creative ideas and produce innovative designs seamlessly. By integrating effective software solutions into your design process, you can significantly improve your workflow and achieve outstanding results with your DTF Gangsheet Builder.

Quality Control: The Key to Successful Printing

Establishing a solid quality control protocol is fundamental in ensuring the success of your DTF printing projects. One of the first steps is to conduct rigorous test prints before launching into full-scale production. This vital measure allows you to appraise color accuracy and print quality firsthand, significantly reducing the risk of costly errors in later stages. Once you are satisfied with the results, you can move forward with confidence, knowing that your designs will meet the expected standards.

Beyond initial test prints, maintaining continuous quality control checks throughout the production process is essential. Develop a systematic approach that includes regular assessments of prints for color fidelity, alignment, and overall print quality. By being proactive in managing standards at every stage, you can mitigate issues that may arise post-production and uphold the quality of your custom apparel. This commitment to excellence not only assures customer satisfaction but also enhances your reputation in the competitive DTF printing market.

Frequently Asked Questions

What are some essential DTF printing tips for using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, select high-quality films and inks specially formulated for DTF printing, familiarize yourself with printer settings, and ensure compatibility between your ink and film. These DTF printing tips are crucial to achieving vibrant, durable prints.

How can effective gangsheet design improve my custom apparel printing?

Effective gangsheet design maximizes the usable area of the gangsheet by grouping similar prints and avoiding edge placements. This leads to reduced material waste and quicker production times, enhancing your custom apparel printing efficiency.

What should I know about gangsheet layout tips when using the DTF Gangsheet Builder?

When designing your gangsheet layout, consider spacing between designs to avoid cutting issues and utilize vector graphics for scalability. These gangsheet layout tips help ensure that your prints turn out crisp and of high quality.

What are the best practices for color management in Direct to Film printing?

Effective color management in Direct to Film printing involves adjusting color profiles for different fabrics and ensuring that your design colors are compatible with the inks used. This ensures accurate color reproduction, vital for high-quality prints.

How does software integration enhance the use of the DTF Gangsheet Builder?

Utilizing graphic design software like Adobe Illustrator or CorelDRAW with the DTF Gangsheet Builder allows for efficient layout creation and streamlined design processes. These tools offer templates and presets that save time and enhance your overall printing workflow.

What is the importance of conducting test prints with the DTF Gangsheet Builder?

Conducting test prints is essential to assess color accuracy and print quality before mass production. This quality control step helps you catch any issues early, ensuring that your final prints meet your standards and reduce material waste.

| Key Point | Explanation |

|---|---|

| High-Quality Films and Inks | Select materials specifically made for DTF printing to ensure durability and vibrancy. |

| Printer Settings | Adjust the printer settings according to the type of DTF film used for optimal results. |

| Compatibility Check | Verify that your inks and films work well together for the best print quality. |

| Maximize the Gangsheet Area | Plan your designs to use the gangsheet space efficiently to avoid waste. |

| Use Vector Graphics | Vector graphics preserve quality at any size; convert text to outlines to avoid font issues. |

| Color Management | Adjust designs based on the materials used to ensure accurate color reproduction. |

| Familiar Graphic Design Software | Use programs like Adobe Illustrator for effective design preparation and layout. |

| Templates and Presets | Leverage built-in templates in the Gangsheet Builder to streamline your workflow. |

| Conduct Test Prints | Print samples before mass production to ensure quality and color accuracy. |

| Quality Control Checks | Implement systematic checks to maintain color accuracy and overall quality in prints. |

| Sort Designs Efficiently | Organize designs by popularity or fabric type to enhance processing speed. |

| Incorporate Feedback | Gather input from customers for continuous improvement of designs and processes. |

| Explore Additional Resources | Utilize online tutorials and guides to gain more insights on using the Gangsheet Builder effectively. |

Summary

Using the DTF Gangsheet Builder effectively involves understanding your materials, design considerations, software tools, and workflow organization. By following the tips outlined above, you can enhance your printing quality, boost efficiency, and stand out in the competitive custom apparel market. Whether you’re selecting high-quality films or utilizing graphic design software, these strategies ensure your prints will not only meet but exceed expectations. Embrace continuous learning and improvement to truly excel in your DTF printing endeavors!