When it comes to custom apparel printing, DTF transfers (Direct to Film) have revolutionized the way designs are applied to fabric. This innovative process allows for vibrant DTF designs to be easily transferred onto various materials, making it a top choice for DIY custom clothing enthusiasts and professionals alike. The DTF printing process simplifies the creation of stunning garments, allowing users to achieve detailed and colorful prints with ease. Understanding how to use DTF transfers can elevate your custom apparel game, whether you’re making items for personal use or business. With DTF, the possibilities for unique, eye-catching designs are virtually limitless.

In the world of custom clothing creation, Direct to Film (DTF) technology has emerged as a game-changer for many designers and hobbyists. This technique allows for high-quality imagery to be printed onto a special film, which can then be applied to fabric surfaces. Known for its ability to deliver crisp and bold graphics, DTF printing not only streamlines the printing process but also enhances the longevity of the designs on garments. Whether you are engaged in DIY fashion projects or operating a custom apparel business, understanding the benefits and applications of DTF technology can lead to exceptional results. Explore this exciting method to add originality and flair to your clothing line.

Understanding DTF Transfers: A Revolution in Custom Apparel

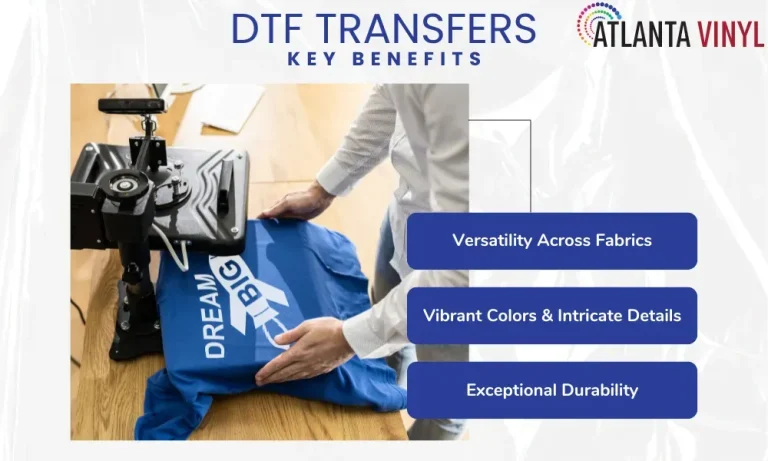

DTF transfers are transforming the way we approach custom apparel printing. This innovative technique involves printing designs onto a special transfer film, which is then heat pressed onto garments. Unlike traditional methods such as screen printing, DTF provides a unique blend of flexibility and quality, making it suitable for small batches or large production runs. Crafters and businesses can now produce detailed designs with vibrant colors that adhere seamlessly to a variety of fabric types.

The versatility of DTF transfers is one of its most significant advantages. With the ability to print on fabric blends, cotton, and even synthetic materials, DTF opens up a world of possibilities for DIY custom clothing. As the demand for personalized fashion continues to grow, understanding and utilizing DTF transfers is becoming essential for any serious custom apparel enthusiast.

The DTF Printing Process: Step-by-Step

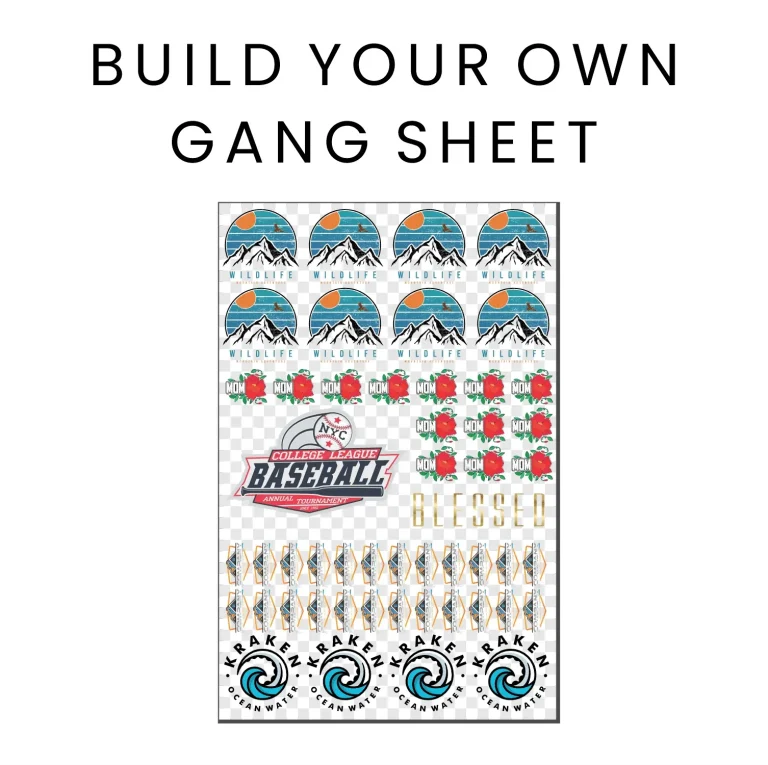

The DTF printing process is straightforward yet requires careful attention to detail to ensure quality results. First, creating your artwork is a crucial step where design software can be used to craft unique graphics. It’s essential to choose bright colors and save your file in a compatible format, like PNG. This process allows for high-resolution images that will translate beautifully onto fabric.

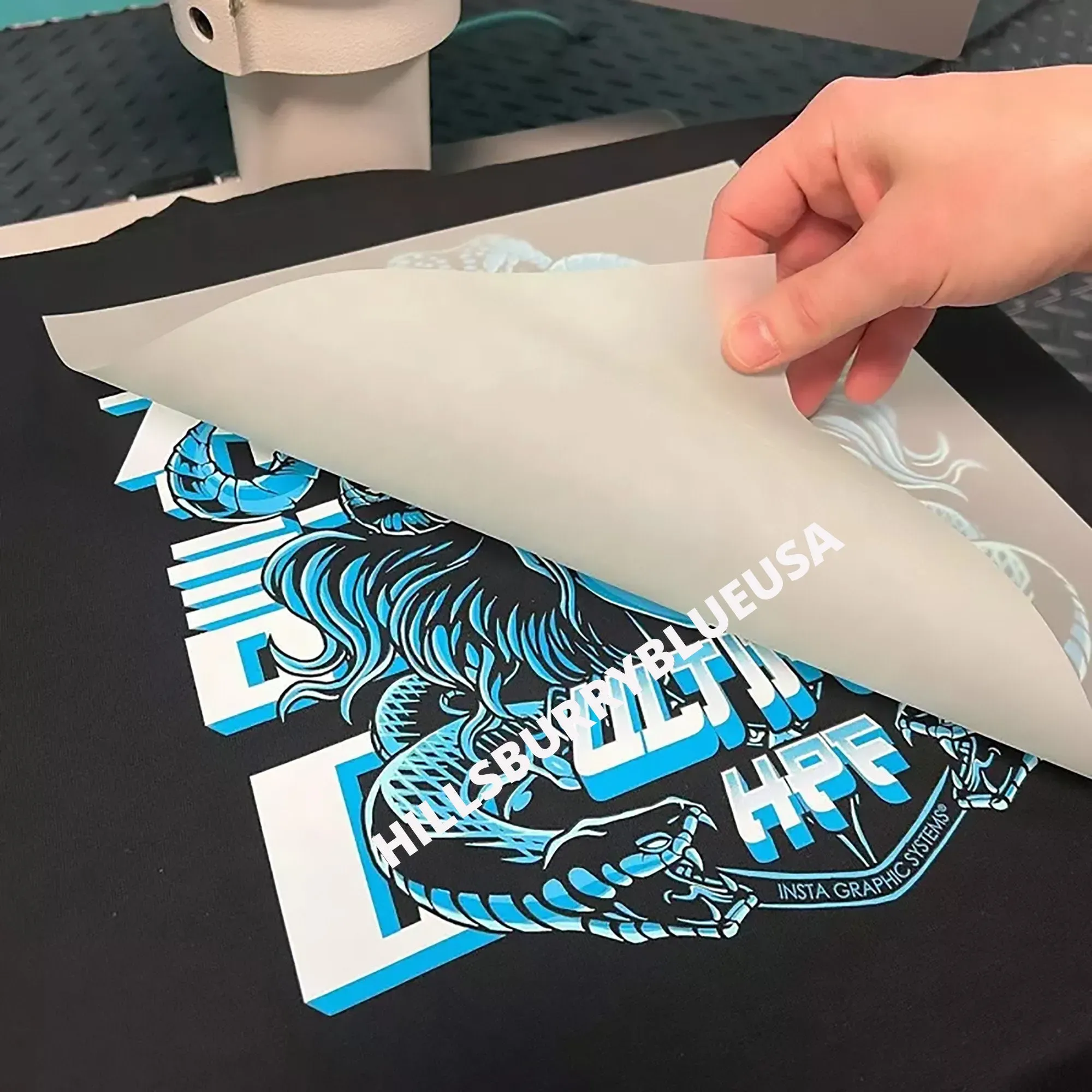

Once your design is ready, the next phase involves using a specialized DTF printer to produce the transfer film. These printers employ eco-friendly water-based inks that yield vibrant outcomes. After printing, the application of powdered adhesive and the curing process ensures that the design adheres permanently to the film, allowing for a crisp and long-lasting final product.

Designing Vibrant DTF Graphics for Custom Apparel

Creating vibrant DTF designs begins with a creative flair and an understanding of color theory. When designing for DTF printing, selecting colors that pop against the fabric is fundamental. A well-thought-out design will not only catch the eye but will also translate properly when printed. Utilizing layers in your design allows for depth and complexity, making your custom apparel stand out even more.

Additionally, it’s vital to consider the fabric type when designing your DTF graphics. Certain colors may show differently on cotton versus polyester blends. This awareness ensures that your final product achieves the intended visual impact, making the graphics more effective in conveying your brand or personal message in custom clothing.

Benefits of Using DTF Transfers for Custom Apparel

DTF transfers come with numerous benefits that make them a preferred choice for custom apparel. One of the primary advantages is their ability to produce high-quality prints that are soft to the touch and durable. Unlike other methods, DTF does not compromise on design detail, allowing for intricate patterns and vivid colors that stay true over time, making them perfect for fashion enthusiasts.

The cost-effectiveness of DTF transfers also cannot be overlooked, especially for those looking to produce small batches of garments. There’s no need for expensive screen setups or complex machinery, which can significantly reduce overhead costs. This flexibility allows smaller businesses to thrive and meet customer demands without straining their budgets.

DIY Custom Clothing with DTF Transfers: A Beginner’s Guide

Venturing into DIY custom clothing using DTF transfers is an engaging way to express your creativity while delivering quality apparel. Beginners can start by gathering essential tools such as graphic design software, a DTF printer, and a reliable heat press. With these basic tools, you can begin transforming your creative designs into wearable art.

Creating your design is an exhilarating process, where you can experiment with colors, themes, and graphics that reflect your style. As you become more familiar with the process of printing and applying DTF transfers, you’ll gain the confidence needed to tackle larger projects or even fulfill custom orders, making DTF a great choice for any budding designer.

Tips for Achieving the Best Results with DTF Transfers

Achieving top-notch results with DTF transfers requires a combination of quality materials and diligent practice. Invest in high-quality DTF films and inks to ensure that your designs come out with clarity and vibrancy. Regular maintenance of your printer and heat press equipment can help prevent issues and ensure that you achieve consistent quality with every print.

Experimentation is also key in mastering DTF printing. Don’t be afraid to test different designs, colors, and materials. This will not only refine your technique but also help you discover what resonates best with your audience if you’re pursuing custom apparel as a business.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, are a modern printing technique used in custom apparel printing. They involve printing designs onto a special film which can then be heat-pressed onto various fabrics. This method allows for vibrant colors and intricate designs, making it an ideal choice for custom clothing.

What is the DTF printing process for creating DIY custom clothing?

The DTF printing process starts with designing your artwork, followed by printing it onto a transfer film. An adhesive is then applied before heat pressing the design onto the fabric. This step-by-step guide makes DTF transfers a perfect choice for DIY custom clothing.

How do I use DTF transfers for my custom apparel designs?

To use DTF transfers for your custom apparel designs, first create your artwork in a compatible file format. Use a DTF printer to print your design onto the transfer film, apply powdered adhesive, heat press it onto your garment, and then peel away the film to reveal your vibrant design.

What benefits do DTF transfers offer compared to traditional printing methods?

DTF transfers offer numerous benefits over traditional methods such as screen printing, including versatility for various fabric types, the ability to print vibrant designs without the need for screens, cost-effectiveness for small runs, and durability against fading and peeling.

Can DTF transfers be used for all types of fabrics in custom apparel?

Yes, DTF transfers are versatile and can be used on a wide range of fabrics including cotton, polyester, and blends. This makes them suitable for various types of custom apparel, ensuring high-quality prints on different garments.

What tips can enhance the quality of DTF designs in custom apparel?

To enhance the quality of DTF designs, experiment with different vibrant colors, use high-quality DTF transfer films and inks, properly maintain your printing equipment, and ensure optimal heat settings during the transfer process to achieve the best results.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A modern printing technique where designs are printed onto transfer film that is then heat-pressed onto fabric. |

| Why Choose DTF Transfers? | Offers versatility, high-quality prints, and cost-effectiveness for small batches without the need for screens. |

| Step 1: Designing Your Artwork | Create a vibrant design using graphic design software and save it in a suitable format. |

| Step 2: Printing the Design | Utilize a DTF printer with optimized settings to print your design on transfer film. |

| Step 3: Applying the Adhesive | Sprinkle powdered adhesive over the wet ink and heat the transfer to bond the ink. |

| Step 4: Transferring the Design to Fabric | Place the transfer on the fabric and use a heat press to apply heat and pressure. |

| Step 5: Peeling and Finishing Touches | Cool the transfer and peel off the film; heat cure again for durability. |

| Benefits of DTF Printing | Versatile for various fabrics, produces vibrant prints, cost-effective for small batches, and durable. |

| Tips for Best Results | Experiment with designs, use quality materials, and maintain your equipment. |

Summary

DTF Transfers provide a revolutionary solution for creating stunning custom apparel, combining ease of use with exceptional quality. With DTF printing, both individuals and businesses can produce vibrant and durable designs that cater to diverse fashion tastes. This method’s adaptability to various fabrics and its cost-effectiveness make it an attractive choice for custom printing, especially for those looking to create smaller batches without breaking the bank. By following a straightforward process from design to application, you can harness the potential of DTF transfers to enhance your apparel offerings and stand out in the marketplace.