DTF printing, or Direct-to-Film printing, is revolutionizing the textile printing industry and altering how custom apparel is produced. This cutting-edge technology allows vibrant designs to be transferred onto various fabrics, making it an increasingly popular choice among manufacturers and consumers alike. As the textile market continues to evolve with a focus on digital textile printing and sustainability, DTF printing stands out for its efficiency and capacity for producing high-quality results. By minimizing waste and embracing eco-friendly practices, DTF transfers are paving the way for a more sustainable future in fabric printing. As we explore the depths of DTF printing, we will uncover the trends that are shaping this innovative technology and its impact on the world of textile printing.

Direct-to-Film printing, often referred to as DTF technology, represents a significant evolution in the realm of custom fabric printing. This modern printing method leverages advanced digital technologies to create striking designs that can adhere to a wide range of materials. As we delve deeper into this transformative approach, you will find its benefits encapsulate not just aesthetic appeal but also a commitment to sustainable fabric printing practices. With a growing emphasis on personalized apparel and efficient production methods, DTF holds the potential to redefine what it means to produce high-quality textiles. This overview will shed light on the rising prominence of DTF and its influence on the future of textile printing.

The Benefits of DTF Printing Technology

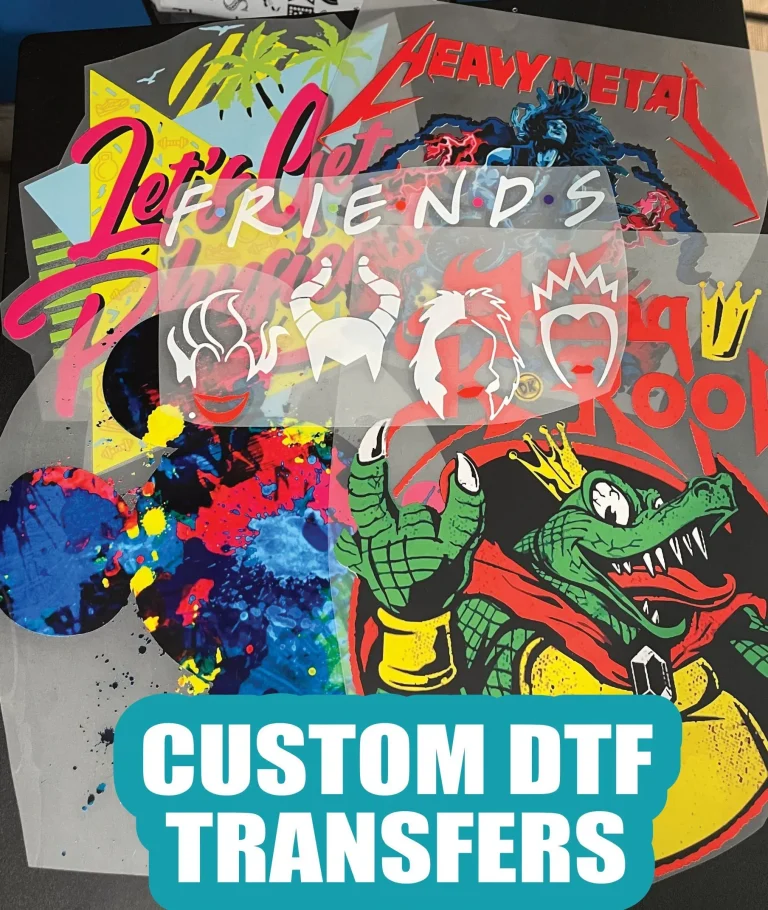

DTF printing technology brings numerous benefits to the textile industry, making it an increasingly popular choice among manufacturers. One of the most significant advantages is the quality of output. The DTF process uses specialized inks that produce vibrant colors and high-resolution prints, ensuring that intricate designs are delivered with precision. This makes DTF an ideal option for custom apparel printing, where detail and clarity are paramount. Additionally, the prints created with DTF technology boast enhanced durability, allowing them to withstand repeated washes without losing their integrity or vibrancy.

Another standout feature of DTF printing is its versatility. Unlike traditional printing methods, which may be limited to specific fabric types, DTF can effectively transfer designs onto a wide range of materials, including cotton, polyester, and blends. This flexibility enables apparel companies to explore various styles and fabrics without the constraints typically associated with other printing techniques. Furthermore, with the rise of trends such as sustainable fabric printing, DTF’s compatibility with eco-friendly inks only adds to its appeal to environmentally conscious brands.

Digital Textile Printing: A Growing Trend

The digital textile printing market is experiencing remarkable growth, fueled by advancements in technology and shifts in consumer preferences. As brands prioritize customization and sustainability, digital printing methods, particularly DTF, have become essential tools for staying competitive. According to market analysts, the digital textile printing sector is expected to expand significantly in the next decade, driven by demand for on-demand services and personalized products. DTF printing specifically is leading this charge, enabling efficient production processes that reduce wait times for consumers.

Moreover, the rise of digital printing technologies aligns well with the growing focus on sustainable fabric printing practices. In an industry long criticized for its environmental footprint, DTF printing offers a solution that emphasizes reduced waste and water usage. The ability to create high-quality, custom apparel without the extensive resource consumption characteristic of older techniques is a game-changer for brands looking to improve their sustainability efforts while meeting the demands of modern consumers.

Sustainable Fabric Printing: DTF as an Eco-Friendly Solution

In today’s conscientious market, sustainability is no longer optional; it is a fundamental expectation among consumers and brands alike. DTF printing technology represents a significant step forward in sustainable fabric printing. By utilizing water-based inks and minimizing waste generation compared to traditional printing methods, DTF printing supports environmentally friendly production practices. This environmentally responsible approach not only appeals to eco-conscious consumers but also helps brands comply with increasing regulatory pressures surrounding sustainability.

DTF printing’s efficiency allows manufacturers to optimize their production processes while still producing high-quality outputs. This dual focus on sustainability and performance makes DTF an attractive option for companies committed to reducing their ecological impact. As the demand for sustainable practices grows, embracing DTF technology positions brands favorably in a competitive marketplace where consumers are increasingly drawn to environmentally responsible choices.

Customization and Personalization in Apparel: The DTF Advantage

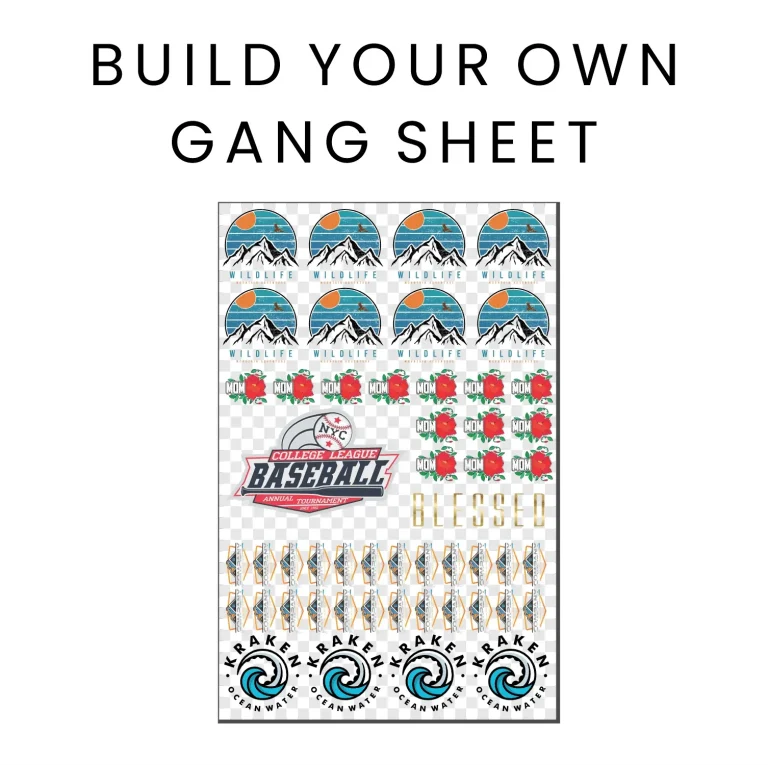

As consumer preferences continue to shift toward customization and personalization, DTF printing stands out as a leading method for meeting these demands. The ability to quickly produce unique designs tailored to specific customer requests is a significant advantage for businesses seeking to enhance their offerings. DTF’s capability to deliver high-quality prints at rapid turnaround times means that brands can keep pace with fast fashion trends while still ensuring customer satisfaction.

Furthermore, the technology’s adaptability allows for a wide range of artistic expression. Whether it’s intricate graphics or simple logos, DTF printing accommodates a variety of design styles, making it an ideal choice for custom apparel printing. This flexibility, combined with its fast production capabilities, enables businesses to efficiently cater to niche markets and target audiences, reinforcing the growing trend of personalized shopping experiences.

Impacts of Technological Advancements in DTF Printing

Technological advancements have played a critical role in enhancing the capabilities of DTF printing. Innovations in ink formulations and printing equipment mean that manufacturers can achieve even greater quality and efficiency with less waste. Modern DTF printers are designed with user-friendly features and streamlined processes, making it easier for businesses to adopt and implement this technology into their production workflows. As these advancements continue, we can expect to see even more businesses gravitating toward DTF solutions.

Additionally, these technological improvements lead to cost reductions in the long run. By decreasing material waste and increasing the speed of production, companies can optimize their operations and reduce overhead costs. This not only enhances profitability but also contributes to a more environmentally conscious manufacturing environment. As these technologies evolve, the future of DTF printing looks brighter than ever, solidifying its position as a key player in the digital textile printing market.

The Future of DTF Printing in the Textile Industry

Looking ahead, the future of DTF printing appears incredibly promising within the textile industry. As market demands continue to evolve toward rapid customization and sustainability, this technology is well-positioned to meet those challenges. The expected expansion of the global digital textile printing market presents a wealth of opportunities for businesses that embrace DTF printing as part of their core strategies. With consumer preferences leaning more toward personalized products, DTF technology enables brands to adapt and respond efficiently.

Moreover, as industries strive for increased sustainability, the eco-friendly nature of DTF printing will likely drive its further adoption. Innovations in digital printing technologies ensure that businesses can produce high-quality textile products with reduced environmental impacts. The combination of quality, versatility, and sustainability inherent in DTF printing makes it a crucial component of the textile industry’s future, paving the way for innovative and responsible fashion solutions.

Frequently Asked Questions

What are the key benefits of DTF printing in custom apparel production?

DTF printing offers several advantages for custom apparel production, including vibrant colors, high resolution for intricate designs, and versatility across various materials. This method is also environmentally friendly, generating less waste than traditional techniques and utilizing water-based inks, aligning with sustainability goals in fabric printing.

How does DTF printing compare to other textile printing technologies?

Compared to other textile printing technologies like screen printing or DTG, DTF printing is more versatile and efficient. It can print on a wide range of fabrics, including cotton and polyester blends, while delivering high-quality outputs. Moreover, DTF’s reduced waste and quicker turnaround times make it an appealing option for on-demand and custom printing needs.

Is DTF printing considered a sustainable fabric printing method?

Yes, DTF printing is recognized as a sustainable fabric printing method. It minimizes waste through its efficient transfer process and employs eco-friendly, water-based inks. This makes it an attractive option for brands and consumers looking to make environmentally conscious choices in their textile products.

What types of fabric can be printed using DTF printing technology?

DTF printing technology is highly versatile, allowing for printing on a wide variety of fabrics such as cotton, polyester, blends, and other textiles. This capability makes it suitable for diverse applications in custom apparel and promotional items.

What advancements are being made in DTF printing technology?

Recent advancements in DTF printing technology include improved ink formulations that enhance color quality and adhesion, as well as more efficient printing equipment. These developments are expected to increase the speed, ease of use, and overall quality of DTF outputs, driving greater adoption in the digital textile printing market.

Why is DTF printing gaining popularity in the digital textile printing market?

DTF printing is gaining popularity due to its ability to produce high-quality, custom designs quickly and affordably, meeting consumer demands for personalization. Its sustainable practices and versatility across various fabrics also align well with current market trends toward eco-friendly and customized textile solutions.

| Key Point | Details |

|---|---|

| What is DTF Printing? | A modern method that transfers designs directly onto fabric via a PET film using specialized ink and heat. |

| The Rise of Digital Textile Printing | The market is growing rapidly due to demand for customized and eco-friendly products, supported by high-performance inks. |

| Benefits of DTF Printing | 1. Quality Output: High-resolution prints with vibrant colors. 2. Versatility: Compatible with various materials. 3. Sustainability: Uses water-based inks, produces less waste. 4. Speed: Fast turnaround times for custom orders. |

| Increasing Prominence of DTF | Companies like Sam’s DTF Transfers showcase the growing acceptance and effectiveness of DTF technology in the market. |

| Current Market Trends | 1. Increased customization demand. 2. Continuous technological advancements in DTF. 3. Trend towards sustainable practices in the textile industry. |

Summary

DTF printing is revolutionizing the textile industry by providing innovative solutions for high-quality fabric decoration. This modern printing method not only produces vibrant and durable designs but also promotes sustainability by minimizing waste and using eco-friendly inks. As the demand for custom apparel surges, DTF printing stands out as the preferred choice for businesses looking to meet contemporary consumer expectations. By embracing its benefits, companies can enhance their product offerings and ensure they remain competitive in a rapidly evolving marketplace.