In the realm of custom apparel printing, DTF transfers, short for Direct-to-Film transfers, are revolutionizing the way designs are applied to fabrics. This innovative technique enables users to create stunning and intricate graphics with great ease, making it an essential tool for both hobbyists and professional print shops. As we delve into the world of DTF transfer techniques, you’ll discover how this method stands out for its ability to produce vibrant, long-lasting prints on various materials. Whether you’re embarking on a beginner DTF printing journey or looking to refine your skills, this guide will provide you with valuable insights to enhance your craft. Unlocking the secrets of DTF transfers opens up a world of possibilities for personalized apparel and unique merchandise.

Direct-to-Film transfer technology has emerged as a game-changer in the world of textile decoration, frequently referred to as DTF printing. This method utilizes a specialized film to apply colorful, intricate designs directly onto fabric surfaces, making it ideal for creating custom apparel that’s both eye-catching and durable. For those new to this printing style, understanding the fundamentals and exploring various DTF printing guides can significantly enhance the creative process. Not only does DTF printing allow for exceptional detail and vibrancy, but it also offers an appealing alternative to traditional printing methods, catering to diverse fabric types. As we explore the intricacies of this innovative printing approach, you’ll be equipped with the knowledge to harness its potential effectively.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is revolutionizing the custom apparel landscape by simplifying the printing process while enhancing the quality of the prints. At its core, DTF printing allows for intricate designs to be printed on a special film that has been treated with an adhesive powder. This innovative technique stands apart from traditional methods such as screen printing, which can often be time-consuming and limited in terms of design complexity. In a world where personalization and uniqueness are valued, DTF provides a solution that meets these needs efficiently.

Moreover, the beauty of DTF transfers lies in their versatility and adaptability to various fabric types. Whether you’re working with cotton, polyester, or blends, DTF printing provides excellent adhesion and durability. This makes it an attractive option not only for fashion and apparel brands but also for independent creators looking to bring their artistic visions to life. By understanding these fundamentals, beginners can appreciate the vast potential DTF printing holds in the world of custom garment decoration.

The Benefits of Using DTF Transfers in Custom Apparel

When it comes to custom apparel, DTF transfers offer numerous benefits that set them apart from traditional printing techniques. First and foremost is the richness of color and detail that DTF printing can achieve. Unlike other methods that might hinder the vibrancy of a design, DTF allows the intricate details to shine, ensuring that every nuance of a graphic is captured perfectly. This is particularly advantageous for designs that require gradients or come with multiple colors, as DTF can print them without compromising quality.

Additionally, DTF transfers are celebrated for their durability. The strong adhesion to a variety of fabrics means that the prints remain intact after numerous washes, making them ideal for apparel that sees regular use. This characteristic not only ensures longevity in the product but also enhances customer satisfaction—an essential factor in the competitive world of custom printing. For anyone venturing into apparel customization, understanding these benefits is crucial to making informed choices about printing techniques.

Finally, DTF transfers are relatively easy to apply, which is a key factor for beginners. With the right equipment and materials, users can start creating high-quality printed garments with relative ease. The straightforward application process of DTF transfers empowers even novice printers to explore their creative side without the intimidation that often accompanies more complex printing methods.

Getting Started with DTF Printing Techniques

For those looking to dive into DTF printing, understanding the techniques involved is essential. Beginners should first familiarize themselves with the equipment needed, including a DTF printer, heat press, and the specific film and powder required for the process. Each component plays a vital role in ensuring that the final product not only looks great but also adheres properly to the fabric. The right setup can vastly improve the overall efficiency and effectiveness of the printing process.

Moreover, mastering the techniques of DTF printing is crucial for achieving professional-level results. This includes learning how to properly adjust print settings for various designs, managing the adherence of adhesive powders, and optimizing heat press temperatures. As beginners practice these skills, they will find that experimentation can lead to discovery, allowing them to fine-tune their approach and develop a distinctive style. Embracing the learning curve is key in successfully leveraging DTF printing in custom apparel.

Common Challenges in DTF Printing and How to Overcome Them

Like any printing method, DTF printing presents its own set of challenges. One common issue that beginners often face is the consistency in the application of adhesive powder. If the powder is applied unevenly, it can result in parts of the design not adhering well to the fabric, which may lead to peeling or cracking over time. To mitigate this issue, it’s important to practice proper testing methods before moving on to larger projects, ensuring that each element of the design will hold up under scrutiny.

Additionally, managing the curing process can also pose difficulties for beginners. Inadequate curing can prevent the design from achieving the necessary durability that DTF is known for. Learning the ideal timings and temperatures is essential to producing high-quality prints that last. To tackle such challenges, joining DTF printing communities—online forums, workshops, or local classes—can provide support and shared experiences that help newcomers navigate these hurdles effectively.

Exploring Advanced DTF Printing Techniques

Once beginners have a firm grasp on the basics of DTF printing, exploring advanced techniques can elevate their work to new levels. For instance, incorporating specialty inks, such as metallic or glow-in-the-dark options, can add an eye-catching flair to designs that stand out in any setting. Understanding how to work with these inks requires an in-depth knowledge of compatibility with various fabrics, but once mastered, the results can be truly stunning.

Furthermore, layering techniques using multiple DTF transfers can help create depth in graphics, elevating the overall aesthetic of the garment. These advanced methods may take time to perfect, but the effort pays off with unique, standout pieces that attract attention. By continuously experimenting and honing their craft, printers can push the boundaries of what is possible with DTF printing, ensuring their custom apparel remains trendy and appealing.

Tips for Marketing Custom DTF Printed Apparel

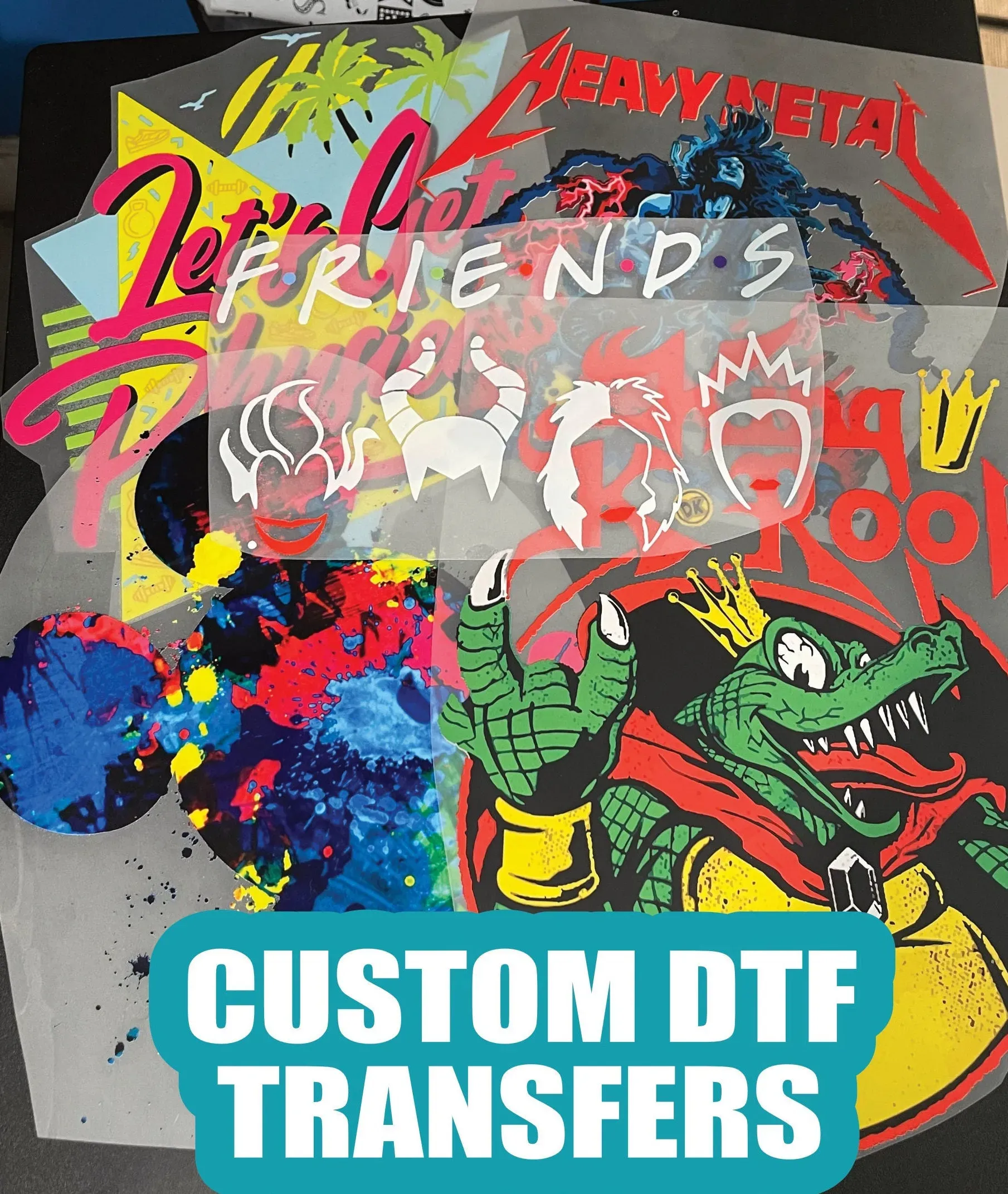

In an ever-competitive marketplace, effectively marketing custom DTF printed apparel is crucial for success. One of the most effective strategies is leveraging social media platforms by sharing high-quality images of printed products that showcase the vibrant colors and details that DTF is capable of. Engaging visual content not only attracts potential customers but also encourages shareability, broadening the reach of marketing campaigns.

Additionally, storytelling plays a significant role in marketing custom apparel. Sharing the process of creating unique designs with DTF printing allows potential customers to connect with the products on a personal level. Highlighting the value of customization and the quality of craftsmanship involved in DTF printing can foster deeper relationships with customers, leading to brand loyalty. Pairing these tactics with promotions or limited-time offers can further entice customers to explore the unique offerings presented in the market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a special film coated with adhesive powder. This process allows for vibrant and intricate designs that are then heat-pressed onto various fabrics, making them durable and suitable for custom apparel printing.

What are the main advantages of using DTF printing for custom apparel?

The primary advantages of DTF printing include its ability to produce high-quality, vibrant designs with intricate details on a variety of fabrics. DTF transfers are more versatile than traditional heat transfer methods, providing excellent durability and color fastness, making them ideal for custom apparel.

How does a beginner start with DTF transfer techniques?

Beginners looking to master DTF transfer techniques should first invest in a DTF printer and compatible inks. Familiarizing themselves with the printing process, selecting suitable films and adhesive powders, and practicing heat pressing on different fabrics are essential steps for success.

Can DTF transfers be applied to all types of fabrics?

Yes, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blends. This versatility makes DTF printing a popular option for various custom apparel projects, allowing for vibrant designs on different textiles.

What is the difference between DTF printing and traditional vinyl printing?

The main difference between DTF printing and traditional vinyl printing lies in the printing method and design quality. DTF transfers allow for more intricate designs and vibrant colors, while traditional heat transfer vinyl (HTV) can limit design complexity and may not be as durable on varied fabric types.

How can I ensure the best quality when using DTF transfers for my projects?

To ensure the best quality with DTF transfers, use a high-quality DTF printer, maintain consistent temperature and pressure during the heat press process, and choose high-grade films and adhesive powders. Proper preparation and careful application will enhance the durability and vibrancy of your custom apparel designs.

| Key Point | Details |

|---|---|

| Definition of DTF Transfers | DTF transfers, or Direct-to-Film transfers, allow for vibrant designs to be printed on fabrics. |

| Printing Process | Involves printing designs on a special film with adhesive powder, then heating for application. |

| Advantages of DTF Printing | Offers high-quality, durable prints on diverse fabric types without design limitations. |

| Comparisons with Other Methods | More versatile and detailed compared to traditional heat transfer vinyl (HTV) methods. |

| Durability | DTF prints are resilient against washing and wear, making them suitable for long-term use. |

Summary

DTF transfers are a revolutionary method in the realm of custom printing, offering vibrant, high-quality designs that can be effortlessly applied to a range of fabrics. This printing technique provides numerous advantages over traditional methods, including the ability to produce intricate designs with durability that withstands regular usage. By understanding the essentials of DTF transfers, enthusiasts and professionals can elevate their printing projects, making their custom apparel truly stand out.