When exploring DTF printing mistakes, it’s crucial to recognize how easily things can go awry in this vibrant printing process. Many beginners and even seasoned printers can fall victim to common DTF errors that compromise the quality of their designs. By understanding these pitfalls, you can implement effective DTF printing tips and techniques to fortify your success in fabric printing. Whether you’re looking to improve DTF prints or troubleshoot DTF printing issues, this guide aims to illuminate the essential steps for better results. Join us as we delve into the key mistakes to avoid and the best practices to achieve stunning prints every time.

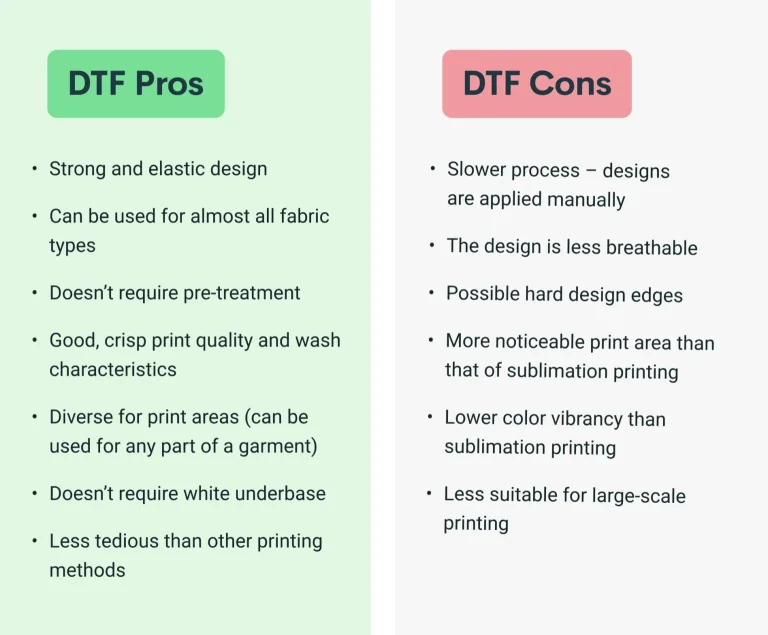

Delving into the world of Direct to Film printing, one quickly learns that mastering this technique plays a significant role in producing striking fabric designs. Despite its popularity, many individuals encounter frequent hurdles that can impede their printing success. Unpacking the fundamental aspects of DTF printing—including missteps and methods for improvement—helps clarify how to navigate this complex craft. From incorrect material selection to improper curing temperatures, understanding each facet is vital for overcoming typical challenges. This article will guide you through various terminologies and practices associated with DTF printing, ensuring you are well-equipped to avoid common pitfalls and elevate your printing projects.

Common DTF Errors and Their Solutions

When delving into DTF printing, it’s easy for beginners and even experienced printers to make common DTF errors that can impact the final result. One prevalent issue is incorrect film selection; utilizing an incompatible film can lead to poor adhesion and print quality. To avoid this, ensure that you choose films that are specifically designed for DTF processes. Selecting the right film not only enhances the quality of your prints but also ensures longevity against washing and wear.

Another common error occurs during the printing process itself, where improper printer settings can cause inadequate ink saturation or poor print resolution. Referring to your printer’s manual for the optimal settings regarding temperature, print speed, and height adjustments is crucial. Additionally, performing test prints can provide valuable insight into the best configurations for achieving clear and vibrant prints.

Understanding DTF Printing Techniques

Mastering print techniques is key to successful DTF printing. Techniques such as the right application of adhesive powder are essential for ensuring durable transfers onto fabrics. Insufficient powder application can result in prints that peel or crack after a few washes. Therefore, utilizing a powder shaker for even distribution is highly recommended to guarantee successful results with your fabric transfers.

In addition to powder application, understanding the curing process plays a vital role in DTF printing. Incorrect curing temperatures and times can leave prints that aren’t fully bonded to the fabric, leading to eventual wear and tear. Curing typically requires a temperature of around 320°F for about 10 to 15 seconds to secure a strong hold, making it critical to monitor this step closely.

Improving DTF Prints through Pre-Treatment

Pre-treatment of the fabric is an often-overlooked critical step in DTF printing that contributes greatly to the quality of the final product. Many newcomers may skip this process, thinking it’s unnecessary, but the truth is that a properly pre-treated fabric allows for better ink adhesion, resulting in more vibrant and durable designs. Investing time in understanding how to pre-treat different types of fabric can yield significant improvements in your prints.

For best results, refer to the guidelines and recommendations specific to the types of fabrics you are using. Understanding the chemical properties of fabric can lead to adjusted pre-treatment methods, which can make a significant difference in the final output of your DTF projects. This knowledge is vital for those looking to elevate their printed designs to a professional level.

Troubleshooting DTF Printing Challenges

Even seasoned DTF printers may encounter unexpected challenges during their printing adventures. Troubleshooting is an essential skill that can save time and resources. Regularly cleaning your printer, particularly the print head, is crucial in preventing streaking or blurriness, ensuring that your prints remain vibrant and clear. Establish a regular schedule to maintain cleanliness, as even minor neglect can cause major disruptions in print quality.

Moreover, familiarizing yourself with common troubleshooting methods can also provide quick solutions to recurring issues. Engaging in communities or forums dedicated to DTF printing can be invaluable for gaining insights from other users’ experiences. The collective knowledge shared within these spaces can guide you through various challenges, enhancing your troubleshooting tactics.

Tips for Successful DTF Printing

To avoid common DTF printing mistakes, staying informed and educated about the latest techniques is essential. Resources such as online tutorials, webinars, and printing courses can provide valuable knowledge, giving you an edge in perfecting your craft. These educational materials often cover everything from basic techniques to advanced troubleshooting tactics, equipping you with the skills necessary to navigate challenges effectively.

Regular practice is equally important; the more you print, the more you learn about the nuances of DTF printing. Experimenting with different materials and configurations can yield useful insights that help you develop a deeper understanding of what works best for your specific needs. In time, this hands-on experience will bring confidence and expertise to your printing process.

Choosing Quality Inks for DTF Printing

The quality of inks used in DTF printing directly impacts the vibrancy and long-lasting qualities of your prints. Opting for inferior quality inks may lead to unsatisfactory results, such as faded colors or inconsistent prints. Therefore, investing in high-quality inks manufactured specifically for DTF applications is essential. It is advisable to research and select reputable brands known for their excellence in DTF solutions.

Quality inks not only enhance the aesthetic appeal of your prints but also contribute to their durability. Prints created with high-quality inks withstand the test of time, maintaining their color and integrity even through multiple washes. Thus, prioritizing ink quality can prevent common printing errors and elevate the overall professionalism of your DTF printed products.

Frequently Asked Questions

What are the most common DTF printing mistakes to avoid?

Common DTF printing mistakes include using the wrong type of film, incorrect printer settings, inadequate powder application, neglecting pre-treatment, inappropriate curing times and temperatures, and using low-quality inks. Identifying and addressing these issues can greatly improve the quality of your prints.

How can I improve DTF prints by avoiding common DTF errors?

To avoid common DTF errors and enhance your prints, ensure you select the right film, configure printer settings correctly, apply adhesive powder evenly, pre-treat fabrics properly, cure transfers at the optimal temperature and duration, and use high-quality inks specifically designed for DTF printing.

What DTF printing tips can help troubleshoot DTF printing issues?

To troubleshoot DTF printing issues, refer to manufacturer guidelines for settings, conduct test prints, consistently check powder application, maintain your printer regularly, and seek advice from online forums or workshops for practical tips on improving results and overcoming common mistakes.

How does improper printer settings lead to DTF printing mistakes?

Improper printer settings can lead to DTF printing mistakes such as insufficient ink saturation or poor resolution. Ensuring your printer settings match the recommended specifications for temperature, speed, and print height can significantly prevent these issues and enhance print quality.

Why is pre-treatment important in avoiding DTF printing mistakes?

Pre-treatment is crucial in DTF printing as it enhances ink adhesion and leads to more vibrant designs. By following specific guidelines for treating your fabric, you can avoid common DTF printing mistakes associated with poor ink bonding, which results in faded or peeling prints.

What are the effects of incorrect curing times and temperatures in DTF printing?

Incorrect curing times or temperatures can result in DTF printing mistakes where prints do not bond properly to the fabric, leading to issues such as cracking or peeling. Ensuring you cure transfers at the recommended temperature and duration is vital for achieving durable and high-quality prints.

| Mistake | Description | Recommendation |

|---|---|---|

| Incorrect Film Selection | Using the wrong type of film affects adhesion and print quality. | Select films specifically manufactured for DTF printing. |

| Improper Printer Settings | Incorrect configurations can lead to inadequate ink saturation or resolution issues. | Refer to the printer’s manual for optimal settings and conduct test prints. |

| Inadequate Powder Application | Insufficient or improper application of adhesive powder can result in peeling prints. | Ensure an even layer of powder using a powder shaker. |

| Neglecting Pre-Treatment | Overlooking pre-treatment can affect ink adhesion and vibrancy. | Follow guidelines for pre-treating your fabric for better results. |

| Incorrect Curing Times and Temperatures | Improper curing can lead to poor bonding of prints to fabric. | Cure transfers at around 320°F for 10-15 seconds. |

| Quality of Inks | Using low-quality inks may lead to fading and inconsistencies. | Choose high-quality inks designed for DTF applications. |

| Cleaning and Maintenance | Neglecting printer maintenance can lead to poor print quality. | Establish a routine cleanup schedule for your printer. |

Summary

DTF printing mistakes can significantly impact the quality of your prints. By addressing these errors proactively, such as choosing the right film and maintaining your equipment, you can ensure that your prints not only look stunning but also stand the test of time. Understanding DTF printing mistakes is essential for anyone looking to master this printing technique, as knowledge and preparation lead to successful outcomes.